H. ZANDER GmbH & Co. KG • Am Gut Wolf 15 • 52070 Aachen • Germany

Tel +49 (0)241 9105010 • Fax +49 (0)241 91050138 •

info@zander-aachen.de • www.zander-aachen.de

2

Emergency Stop Safety Relay SR3C

M03

Ver. B

E61-137-00

Operating Instructions

English translation

Errors and technical changes reserved

Note:

The items listed under “Electrical connection” must be observed during commissioning.

Commissioning

Procedure

5. Starting the device:

Switch on the operating voltage.

Warning:

If the “Automatic start” starting behavior is set, the safety

contacts will close immediately.

If the “Monitored manual start” starting behavior is set, close

the start button to close the safety contacts.

LEDs

K1

and

K2

are lit.

6. Triggering safety function:

Open the emergency stop circuit by actuating the connected

safety switch. The safety contacts open immediately.

7. Reactivation:

Close the emergency stop circuit. If “Automatic start” is

selected, the safety contacts will close immediately.

If the “Monitored manual start” starting behavior is set, close

the start button to close the safety contacts.

Fig. 6:

Monitored manual start.

It is monitored that the start

button was opened before the

emergency stop button closes.

(Prerequisite: operating voltage

must not be interrupted.)

Fig. 7:

Automatic start.

Max perm. delay during closing

of the safety switches on S12

and S13:

S12 before S13: 300 ms

S13 before S12: any

Warning:

Safety contacts switch

immediately when the

power supply is connected.

Depending on the application or the result of the risk assessment according to EN ISO 13849-1, the device must be wired as

shown in Fig. 1 to Fig. 11.

Applications

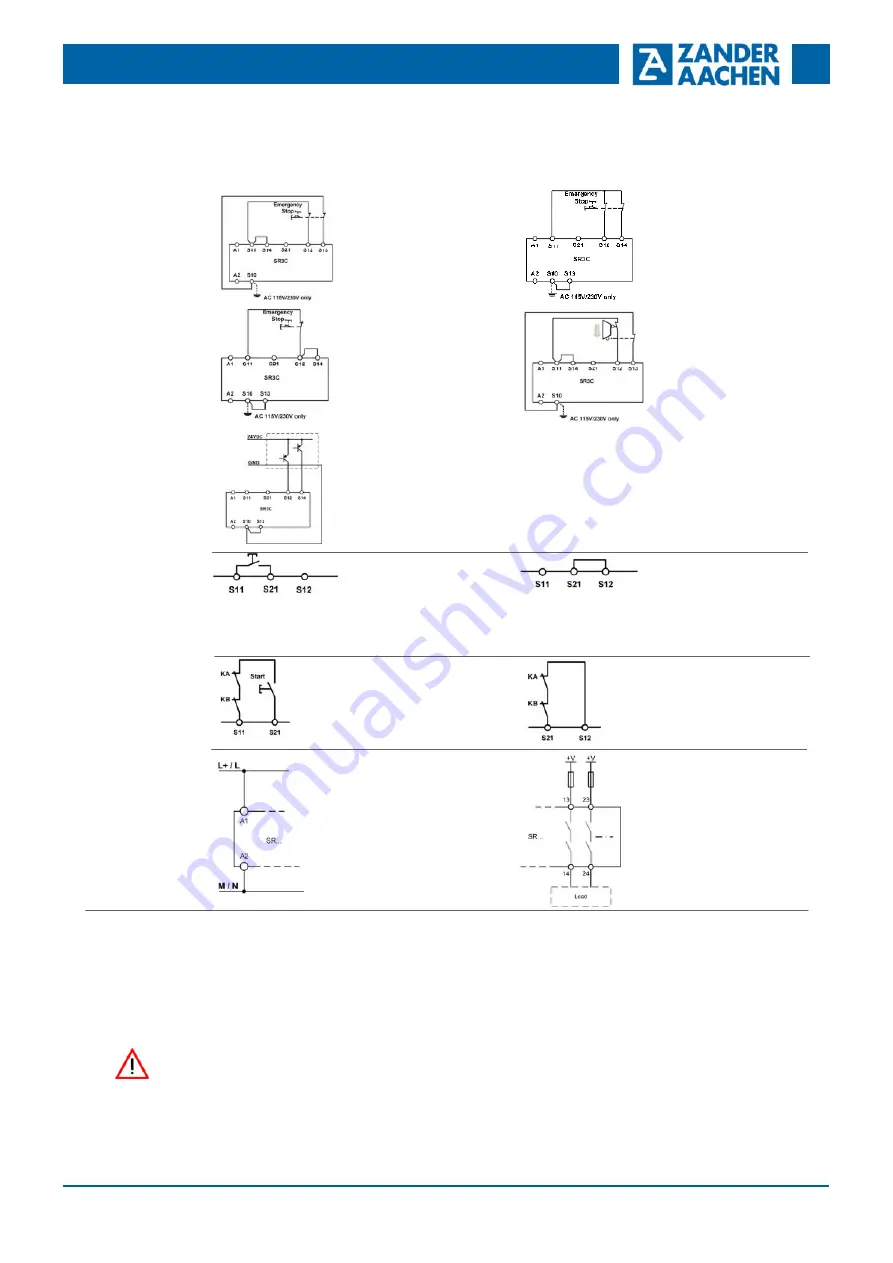

Fig. 3:

Single-channel emergency stop

circuit with earth fault monitor-

ing.

(category 1, up to PL c)

Fig. 2:

Two-channel emergency stop

circuit with earth fault monitoring.

(category 3, up to PL d)

Fig. 1:

Two-channel emergency stop

circuit with short circuit and

earth fault monitoring.

(category 4, up to PL e)

Fig. 4:

Two-channel sliding guard

monitoring with short circuit and

earth fault monitoring.

(category 4, up to PL e)

Emergency Stop

Circuit

Starting Behavior

Fig. 8:

Feedback loop for monitored

manual start:

The feedback loop monitors

contactors or the expansion

modules .

Feedback Loop

Fig. 9:

Feedback loop for automatic

start:

The feedback loop monitors

contactors or the expansion

modules .

Power supply

and

Safety contacts

Fig. 10:

Power supply A1 and A2.

(Power supply according to

techn. Data )

Fig. 11:

Connecting load to safety con-

tacts.

(Figure shows example.

Voltage „+V“ according to techn.

Data)

Notice:

In order to activate earth fault monitoring, S10 must be

connected to PE (protective earth) on the AC 115/230 V

devices. With AC/DC 24 V, connect PE only to the power

supply unit according to EN 60204-1

Corresponded to the application, the starting circuit have to

be wired according to Fig. 6 or Fig. 7.

Fig. 5:

Two-channel emergency stop

with pnp-outputs/OSSD-outputs

with

short circuit monitoring.

(category 4, up to PL e)

1. Input circuit:

Depending on the risk evaluation choose one of the wiring

diagrams in „Applications“ (Fig. 1 to 5).

2. Choose start mode:

Connect the start button with S11 and S21 for monitored

manual start or connect S21 with S12 directly for automatic

start (Fig. 6 or 7).

Warning:

If “Automatic start” is set, bear in mind that the safety con-

tacts will switch immediately after the power supply is

connected. If “Monitored manual start” is set, the start

button must be opened after wiring.

3. Feedback loop:

If external contactors or extension modules are used,

connect them according to Fig. 8 or Fig. 9.

4. Power supply:

Connect the power supply to A1 and A2 (Fig. 10).

Caution:

Power must not yet be activated.