39

Mod. KERA rev 01

Installation

translated from the original text

EN

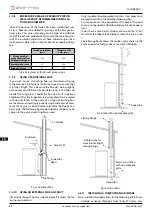

Connection without the DHW kit

fig. 10 connection points without a DHW kit

Ref.

Description

1

Radiator H2O supply ¾”

2

H2O exhaust pipe safety valve ½”

3

Radiator H2O return ¾”

4

H2O hydraulic line input ½”

2.5.6

FLUE GAS EXHAUST DUCT

The exhaust pipe must be constructed by special-

ised, skilled personnel or companies, according to

the indications in this manual. The exhaust system

must be made in such a way as to ensure easy pe-

riodic cleaning without having to disassemble any

parts.

The pipes must ALWAYS be installed according to the standards

and instructions of the manufacturer and anyway with the silicon

gasket supplied to guarantee its sealing.

• IT is prohibited to install dampers or other valves that can

obstruct the flue gas exhaust.

• IT is prohibited to install one flue in which flue gas or vapours of

other appliances (boilers, hoods, etc.) are exhausted.

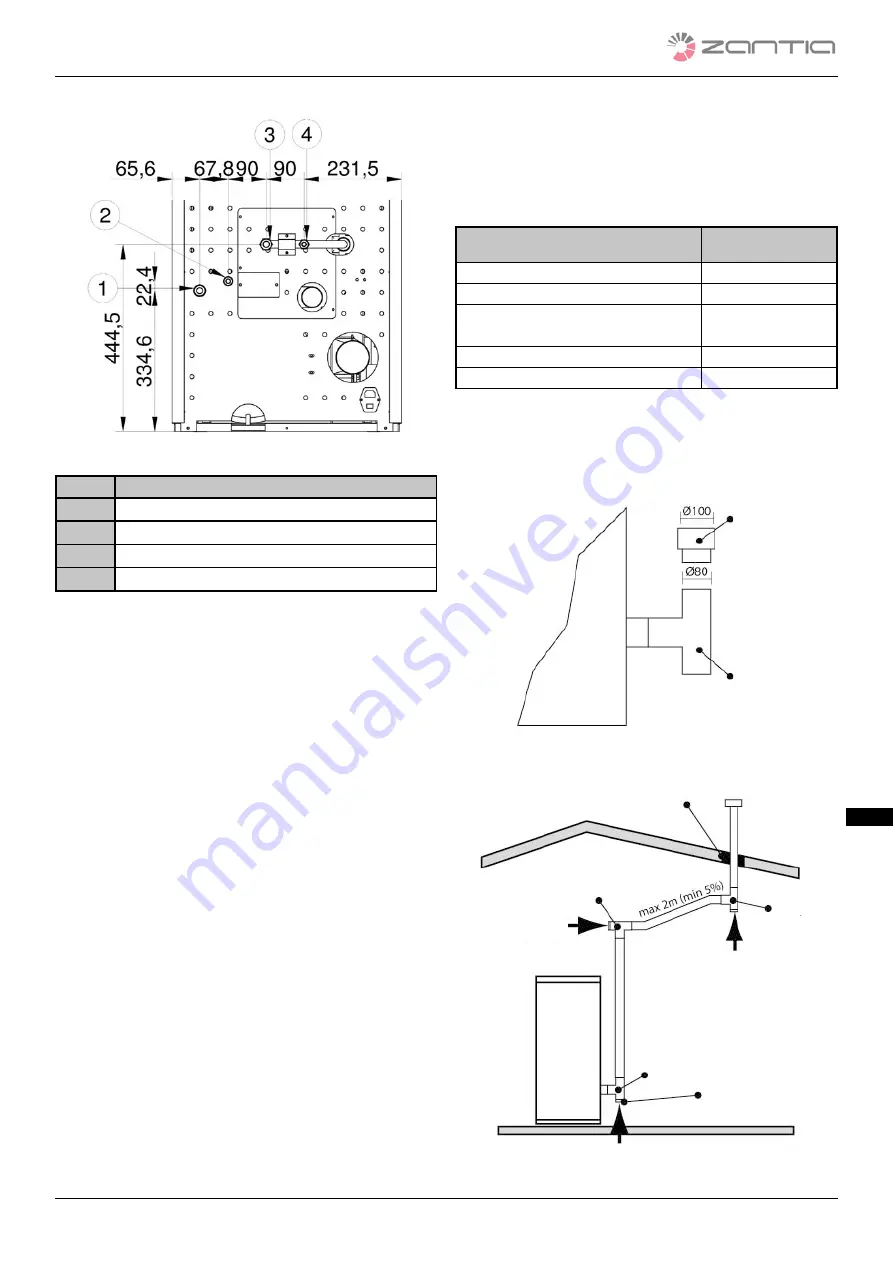

2.5.7

PIPES AND MAXIMUM USABLE LENGTHS

Pipes made of painted aluminised steel (minimum thickness

1.5 mm), stainless steel (Aisi 316) with a 100 mm diameter (for

pipes inside the flue max. 150 mm). Hoses are prohibited; the

male-female coupling collars must have a minimum length

of 50 mm. The diameter of the pipes depends on the type of

system.

TYPE OF SYSTEM

WITH Ø 100 mm DOU-

BLE WALLED PIPE

Minimum length

2m

Maximum length (with 3 90° elbows)

8m

For installations located at over 1200 m asl

mandatory

Maximum number of elbows

4

Horizontal segments with min slope 5%

2m

tab.3 max. pipe length

NOTE: pressure drops of a 90° elbow can be com-

pared to those of a 1 metre pipe; the inspection

tee fitting must be considered as a 90° elbow. Re-

fer to the standards in force in question.

fig. 11 pipe length

Tee fit-

ting

Fitting

Insulation

Tee fitting

Tee fitting

Airtight cap

Tee fitting

Cleaning

direction

Cleaning

direction

Cleaning direction