25

3. Operation Instr uctions

Serial Number

12-15

10-13

8-12

10-15

8-12

5-10

4-8

0

(

OFF

),

1

(

ON

)

0

(

OFF

),

1

(

ON

)

14

1 2

1 0

1 2

1 0

7

5

1

0

1

2

3

4

5

6

7

8

9

Possible causes

Error Code Displayed

Air inlet temperature sensor failure

Water inlet temperature sensor failure

DC motor failure

Wired controller temperature sensor failure

Wired controller humidity sensor failure

Bottom wired controller communication failure

485 wired controller communication failure

E

1

E

2

E

3

E

4(

parameter 9 valid

)

E

5(

parameter 9 valid

)

E

6

E

7(

parameter 9 valid

)

1

2

3

4

5

6

7

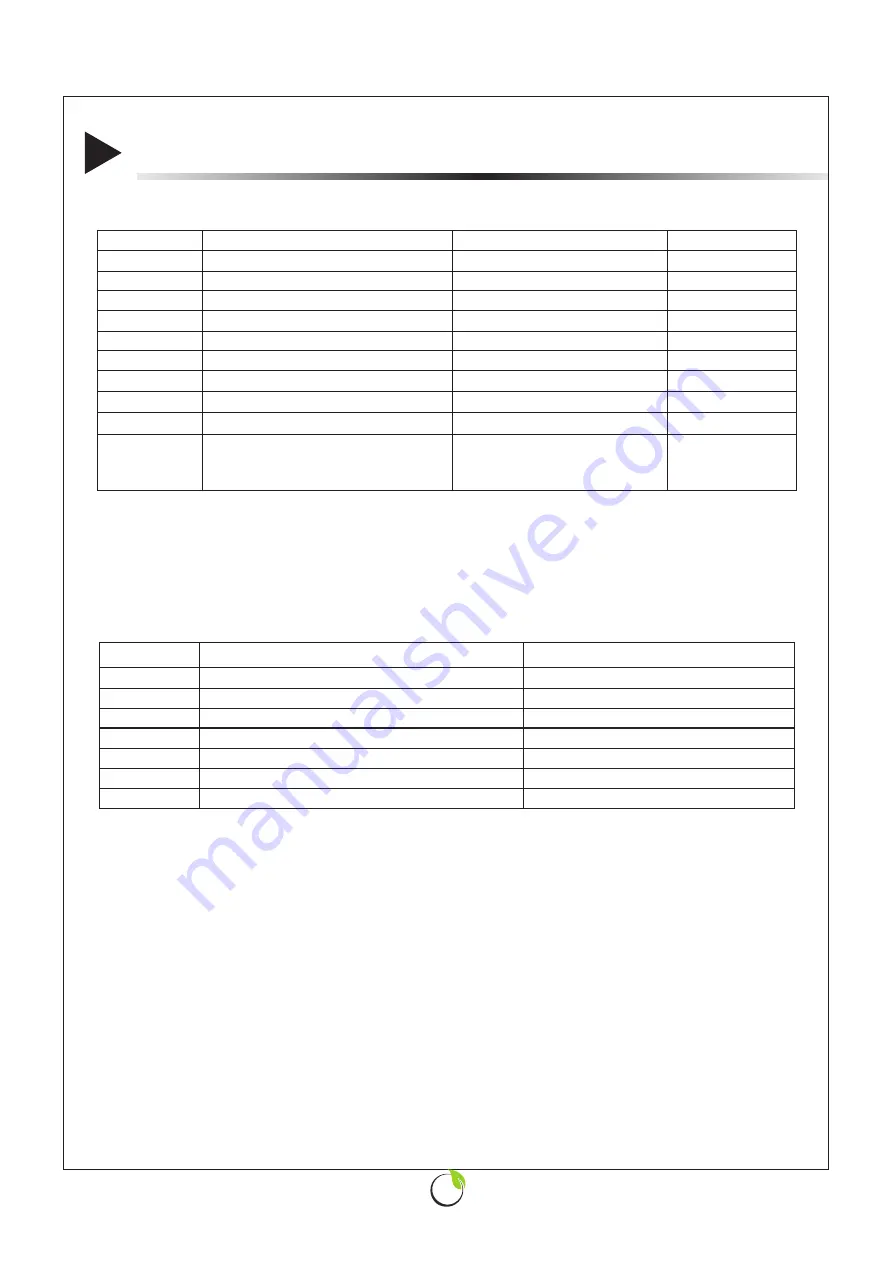

(11) Parameters

Meaning

Range

Default Setting

High fan speed of cooling

Medium fan speed of cooling

Low fan speed of cooling

High fan speed of heating

Medium fan speed of heating

Low fan speed of heating

Super low fan speed of heating

Valve functions

485 communication

Ps

:

Actual fan speed = Setting fan speed * 100

(12) Failure

code

Failure code will flash on the display

.

Multiple failure code will come in sequence

on the display

Serial Number

Failure code shows up when:

1. Air inlet temperature sensor failure: Cancel room temperature control, the error code

shows

up

.

2. Water inlet temperature sensor failure: Cancel water inlet temperature limit, the error code shows

.

3. DC motor failure

:

The unit stops running, the error code

shows

up

.

4. Wired controller temperature sensor failure

:

Cancel room temperature control, the error code

shows

.

5. Wired controller humidity sensor failure

:

It only shows the error code.

6. Bottom wired controller communication failure

:

It only shows the error code.

7. 485 wired controller communication failure

:

The unit stops running, the error code

shows

up

.

10

ON/OFF of display

0(OFF in 5min without

operation of unit is off),

1(always on)

1

Summary of Contents for SLIM-C Series

Page 2: ......

Page 34: ...31 5 Appendix 5 1 Exploded view...

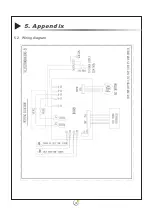

Page 36: ...33 5 2 Wiring diagram 5 Appendix...

Page 38: ...NOTES...

Page 39: ......

Page 40: ...www ZAN TIA com...