6

3 - USE OF COOKING HOB

Fig. 3.1

GAS BURNERS

Each burner is controlled by a gas tap

assuring the opening and the closing of

the gas supply.

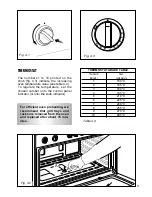

Make the symbols printed on the knob to

match with the indicator on the control

panel to obtain:

– symbol

●

: off

– symbol

: full on (nominal rate)

– symbol

: reduced rate

To light one of the gas burners, hold a

flame (i.e. a match) close to the top part

of the burner, push in and turn the relati-

ve knob in an anti-clockwise direction,

pointing the large flame symbol (i.e.

max. gas flow) towards the indicator on

the control panel.

To reduce the gas flow to minimum,

rotate the knob further anti-clockwise to

point the small flame symbol towards

the control panel indicator.

The maximum aperture position permits

rapid boiling of liquids, whereas the

minimum aperture position allows slower

warming of food or maintaining boiling

conditions of liquids.

Other intermediate operating adjust-

ments can be achieved by positioning

the indicator between the maximum and

minimum aperture positions, and never

between the maximum aperture and

closed positions.