20

www.zanussi.com

Gas information

To tighten some components apply the

following torque forces:

Aluminium pipes to burners, valves,

thermostats: 15 Nm

Thermocouples to top burners cups: 3

Nm

Thermocouples to thermostats: 4 Nm

Push-on connector: 20 Nm

Injectors: 4 Nm

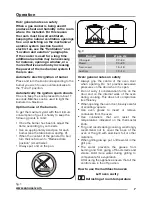

Fig. 10

Conversions

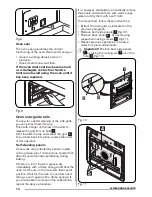

Replacing the injectors

Our burners can be adapted to different

types of gas by simply installing the injectors

suitable for the gas you want to use.

To change the injectors on the hob, remove

the burner cup and head and with a 7 mm Ø

socket spanner replace them (fig. 11).

To help the installer, the table on in the

“Technical information” section.

gives the

burner nominal heat input, injector diameter

and operating pressure of the different gas

types.

After having replaced the injectors, it

will be necessary to proceed with burner

adjustment as explained in the previous

paragraphs. The technician must replace

any seals after the adjustments have

been made.

Fig. 11

Maintenance

Prior to any maintenance work or

changing parts, disconnect the

appliance from the gas and electricity

power sources.

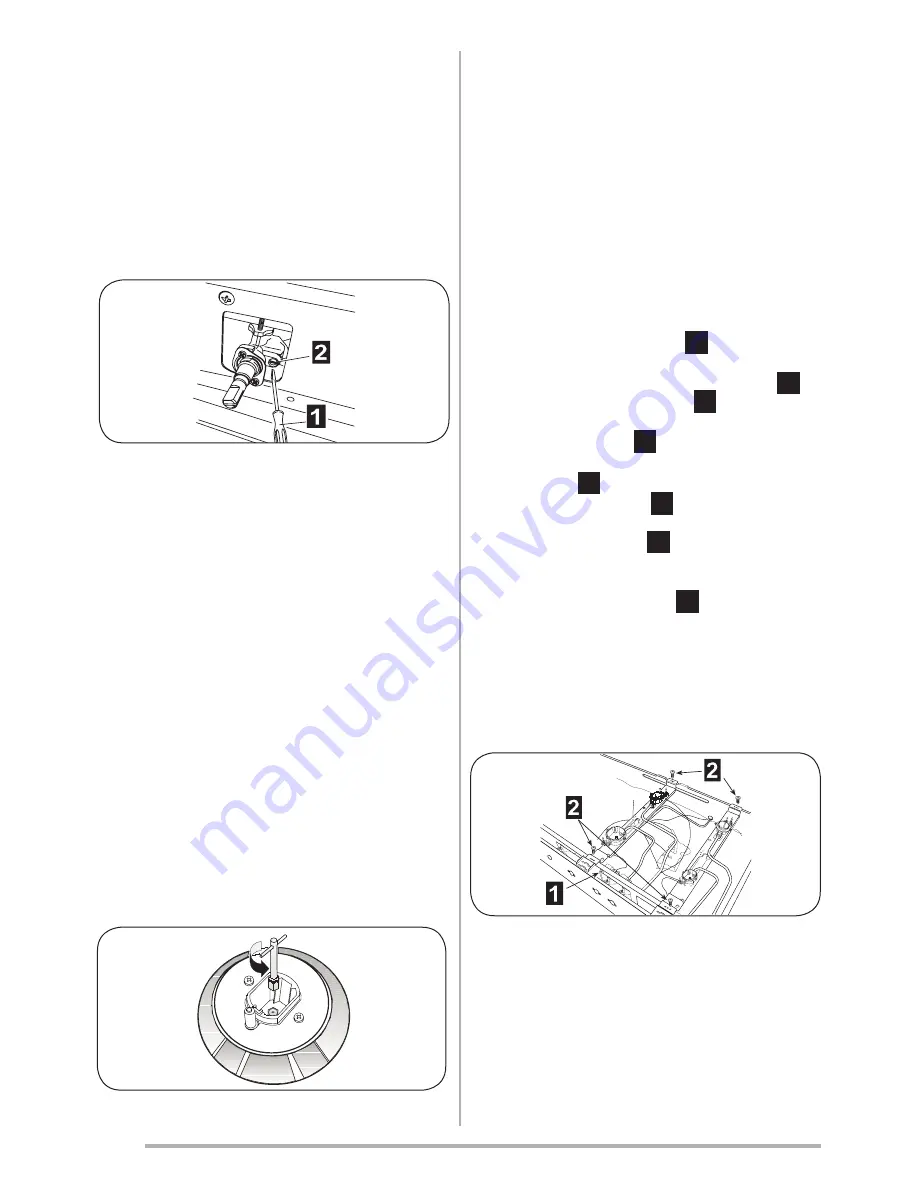

Replacing the taps

Proceed in the following way when replacing

a tap or the thermostat:

• Remove pan supports, burner heads.

• Unscrew the burner fixing screws (four

for ultrarapid burner and two for the other

burners)

• Pull out the knobs.

• Unscrew the fixing screws

1

(fig. 14) which

lock the front panel to the front frame then

slip out from the upper fixing brackets.

2

• Unscrew the fixing screws

1

(fig. 14 which

lock the hob at the back and remove it.

• Unscrew the nuts

2

of the gas aluminium

pipes and pull out the thermocouple quick

connectors

3

(fig.13).

• Unscrew the screws

2

(fig. 12) which lock

the crosspieces.l

• Unscrew the screws

1

(fig. 12) which unite

the the bridles of the taps to the front frame.

• Make to slip the ramp toward the back part

and unscrew the screws

1

(fig. 13) in order

to free the taps.

• Change seal each time a tap is replaced.

This will ensure perfect retention between

the tap and part.

• Reassemble all the parts following the same

procedure but in the reverse order.

Fig. 12