8

The appliance is designed to be connected to 230 V

monophase electricity supply.

The connection must be carried out in compliance with

the laws and regulations in force.

Before the appliance is connected:

1) check that the main fuse and the domestic installation

can support the load (see the rating label);

2) check that the power supply is properly earthed in

compliance with the current rules;

3) check the socket or the double pole switch used for

the electrical connection can be easily reached with

the appliance built in the forniture unit.

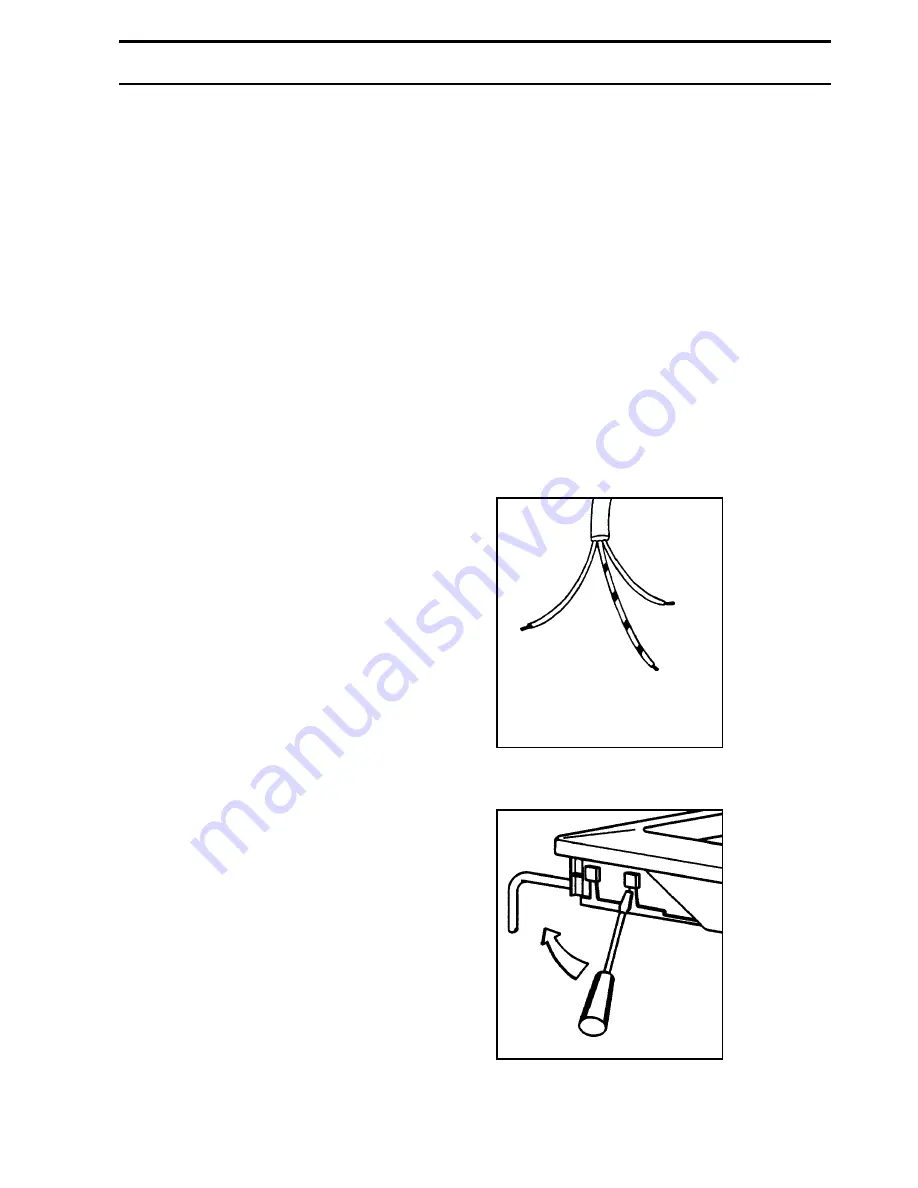

The appliance is supplied with a connection cable. This

has to be provided with a proper plug, able to support the

load marked on the identification plate. To connect the

plug to the cable, follow the recommendation given in

Fig. 8. The plug has to be fitted in a proper socket.

If connecting the appliance directly to the electric system,

it is necessary that you install a double pole switch

between the appliance and the electricity supply, with a

minimum gap of 3 mm. between the switch contacts and

of a type suitable for the required load in compliance

with the current rules.

The earth cable (yellow/green) must not be interrupted

by the interrupter.

The connection cable has to be placed in order that, in

each part, it cannot reach a temperature 90

°

C higher

than the room temperature.

The brown coloured phase cable (fitted in the terminal

block contact marked with "L") must always be connected

to the network phase.

REPLACEMENT OF THE VOLTAGE CABLE

The connection of the voltage cable to the appliance's

terminal block is of type "Y". This means that its

replacement requires the specific equipment of a

technician.

In this case, only cable type H05V

2

V

2

-F T90 must be

used. The cable section must be suitable to the voltage

and the working temperature.

The yellow/green earth wire must be approximately 2

cm. longer than the phase wires (Fig.8).

To open the terminal block and reach the terminals,

proceed as follows:

●

insert the point of a screwdriver into the visible

protrunding part of the terminal block;

●

exert a light pressure and lift (Fig. 9)

7. Electrical Connection

Fig. 8

Fig. 9

FO 0073

FO 0257

Neutral

Earth (yellow/green)