14

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

○

GB

cases, if the ceiling is not strong enough in the area where the hood is to be fixed, the

installer must strengthen the area using suitable plates and counterplates anchored to

resistant structures.

Fixing to the Wooden Buttress

• Connect the base of the frame to the beam using the 4 screws size 5.2x70 with nuts and

washers, provided in bag (1)

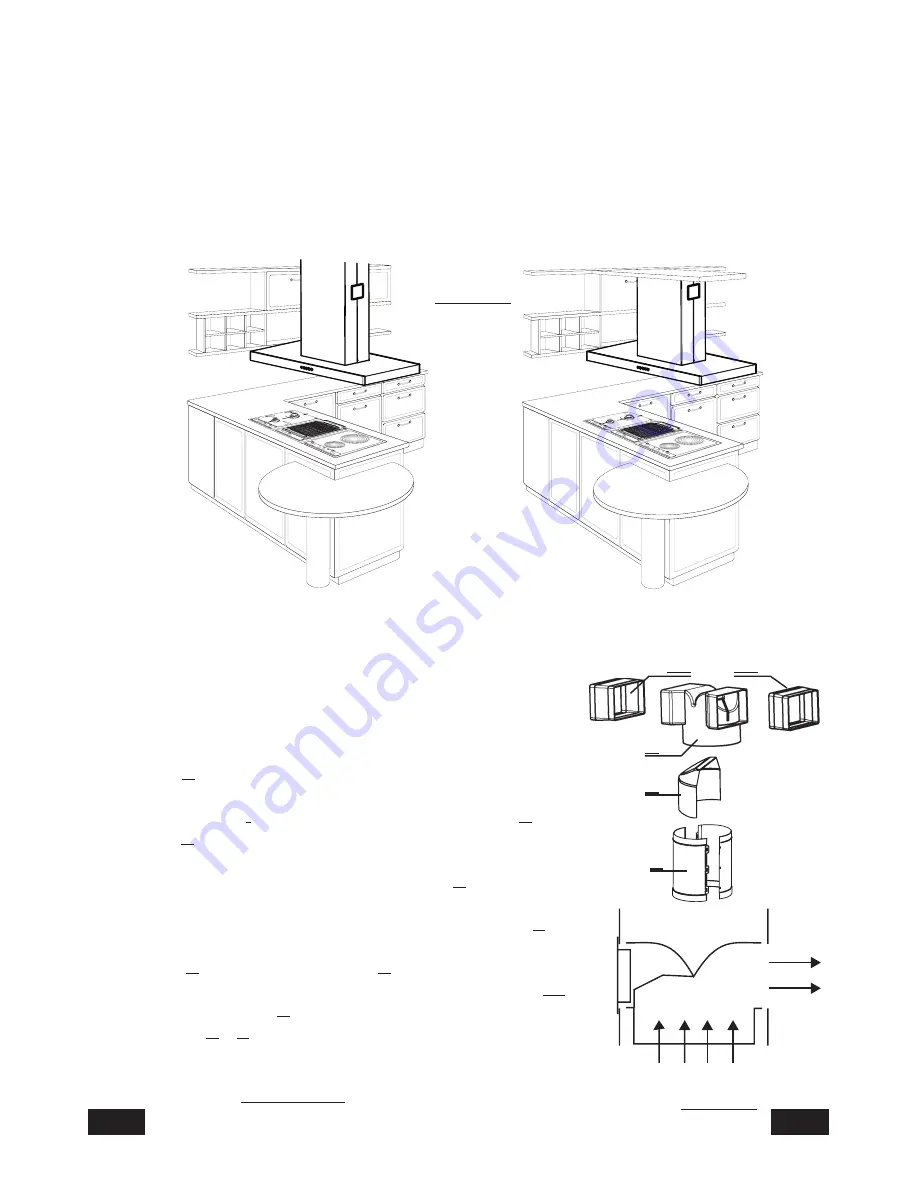

Ducting or recirculation fitting

• Ducting fitting

• The hood can be connected to the ducting by means of

a rigid or flexible pipe Ø 120 or 150 mm, the choice of

which is left to the installer. When installing with the

pipe Ø 120 mm, it will be necessary to use the reduction

flange

A

on the hood outlet.

• To install the hood with the side air outlet from lower

chimney stack

I

, it is necessary to insert deflector

D

into

spigot

R

so as to close off the opening that is not being

used (

fig. 3

).

•

Cut

additional recirculation spigot

P

at a point

corresponding to outlets 1 and 2, indicated directly on

the piece. Connect additional recirculation spigot

P

to

the round diffuser outlet, pushing it downwards, and fit

spigot

R

to additional spigot

P

in a similar manner

(ensure that the two additional recirculation spigots

P1

are fitted to spigot

R

). Make sure that the height of the

assembly

R

+

P

corresponds to the height of the chimney

outlet.

• Remove

the activated charcoal filters, if fitted (see

paragraph on

Maintenance

).

D

R

P1

P1

P

Fig. 3

Fig. 2

A

B

8

7

65

43

2

1

8

7

6

5

43

2

1

8

7

6

5

4

32

1

8

7

65

43

2

1

8

7

6

54

3

2

1

8

7

6

5

43

2

1

8

7

6

5

43

2

1

8

7

6

54

32

1