Installation

Unpacking

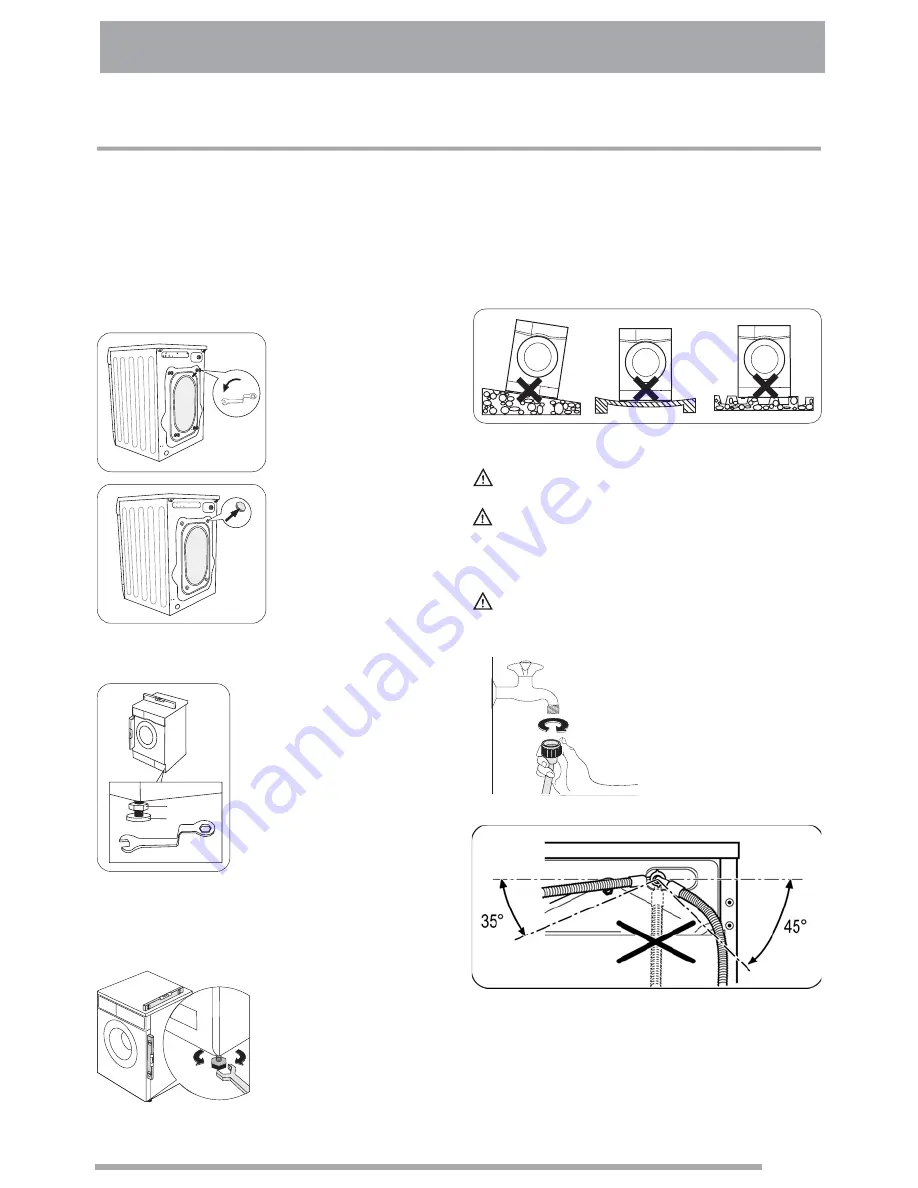

Positioning

All transit bolts and packing must be removed before

using the appliance.

You are advised to keep all transit devices so that

they can be refitted if the machine ever has to be

transported again.

Unscrew the four bolts

using a spanner.

Slide out the relevant

plastic spacers.

Fill the holes with the

corresponding plastic

plug caps supplied in the

bag containing the

instruction booklet.

Install the machine on a flat

hard floor. Make sure that air

circulation around the machine

is not impeded by carpets, rugs

etc. Check that the machine

does not touch the wall or other

kitchen units. Level the

washing machine by raising or

lowering the feet. The feet may

be tight to adjust as they

incorporate a self locking nut,

but the machine MUST be level and stable.

Any necessary adjustment can be made with a

spanner.

If necessary, check the

setting with a spirit level.

Accurate levelling prevents vibration, noise and

displacement of the machine during operation. Never

place cardboard, wood or similar materials under the

machine to compensate for any unevenness in the

floor.

This appliance must be connected to a

cold water supply.

Before connecting up the appliance to

new pipework or to pipework that has not been

used for some time, run off a reasonable amount of

water to flush out any debris that may have collected

Do not use the hose from your previous

appliance to connect to water supply.

Connect the hose to a tap

with a 3/4” thread.

Always use the hose

supplied with the

appliance.

The other end of the inlet hose which connects to the

appliance can be turned as showed in the picture. Do

not place the inlet hose downwards. Angle the hose to

the left or right depending on the position of your

water tap. Set the hose correctly by loosening the ring

nut. After positioning the inlet hose, be sure to tighten

the ring nut again to prevent leaks.

Water inlet

Caution!

Caution!

Caution!

1

2

19

Summary of Contents for ZWF1000M

Page 1: ...ZANUSSI Manual User Machine Washing ZWF180M ZWF1000M ...

Page 21: ......

Page 22: ...ZANUSSI ...

Page 23: ......

Page 24: ...ZANUSSI www zanussi co uk www zanussi be Subject to change without notice ...