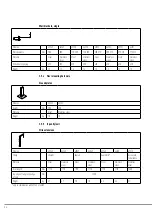

4.3 Special notes

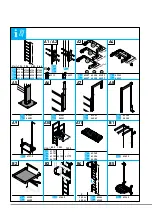

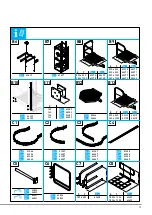

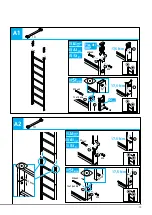

The installation instructions are presented in the form of diagrams.

For installation instructions,

see the illustrations section,

A1

to

C9

The following must also be observed:

– Safety instructions in the section "Safety instructions" (p. 38).

– The notes below on the individual installation steps.

Double-sided wall brackets (U-shaped bar that fixes both sides of the ladder), single-sided wall brackets

– Check that the surface of the substructure is flat and perpendicular; use adjustable

wall brackets if necessary.

– Mount each ladder segment with at least two double-sided U-shaped bars or four

single-sided wall brackets.

• If you intend to install the wall brackets using a screw anchor system, only use ones

that have been approved by the building control authority. The company carrying out

installation is responsible for the work and must examine the masonry thoroughly.

If you are unsure of anything, contact an expert in structural engineering or a technical

consultant from the manufacturer of the screw anchors (mandatory in accordance

with DIN 14094-1). The attachment hardware of each wall bracket must be able to

withstand a total pull-out force of ≥3 kN and, when used in combination with a fall

arrester system (e.g. the ZARGES ZAST fall arrester system), an impact force of ≥6 kN.

Screw anchors are not included in the scope of delivery.

• Standard static calculations are available for wall brackets ..257, ..258, ..259, ..260.

For wall brackets ..261, ..262, static calculations must be requested individually

for each construction project.

• For version with security door:

– Do not attach wall brackets in the area of the hinge attachments.

• For version with emergency exit ladder:

– Countersink drilled hole for attachment of the fixed ladder.

– Use countersunk head screws.

– Restore anti-corrosion protection in the area of the countersink.

Ground plate

Two ground plates can be used instead of the bottom wall bracket.

Landing rail (with floor bracket)

• Use only in combination with stile extension (43243/44243).

Landing rail, angled

• Mandatory within the area of application of DIN 14094-1.

Landing with crossover

The crossovers are designed for a maximum moving working load of 150 kg. They are not

designed as collection or storage points for increased working loads or stationary loads.

The exit ladder must be attached to the building using wall brackets or ground plates.

Installation with ground plates is described in the illustrations section.

If fall protection (guardrails) is required at the sides (e.g. to comply with DIN 18799-3),

it must be provided by the operator.

A3-A4

A5

A8

A10

40

Summary of Contents for 41286

Page 61: ...4 3 B2 1 2 13 17 5 Nm 2 2 1 M8 M8 M8x65 2 1 3 17 5 Nm 4 3 B3 1 2 1 3 61...

Page 63: ...4 3 B5 1 2 M8 M8 17 5 Nm M8 M8 13 2x 17 5 Nm 1 1 2 2 4 3 B6 1 2 M8 M8 17 5 Nm 1 2 13 2x A19 63...

Page 64: ...4 3 B7 1 M8 M8 17 5 Nm 2 13 2x...

Page 68: ...4 3 B12 1 2 3 1 2 13 17 5 Nm 0...

Page 72: ...4 3 C8 13 2x 1 2 10x 1 2 3 4 4 3 C7 13 2x 1 2 1 1 2 4 3 17 5 Nm 5 5 6 17 5 Nm...

Page 73: ...4 3 C9 10 73...