• Screws and nuts:

– Use screws and nuts from ZARGES or screws and nuts of equivalent quality.

– Secure screwed connections with self-locking nuts.

– To ensure easy and safe assembly, use a suitable high-performance anti-wear

agent designed for heavy-duty use on stainless steel screws in the assembly area.

ZARGES recommends the product Chaast manufactured by the company Hebro.

– Tighten screws to the following torques:

Dimensions

Tightening torque (Nm)

M6

7.5

M8

17.5

M10

25.0

M12

60.0

4.2 Recommendations for installation

4.2.1 Preparation

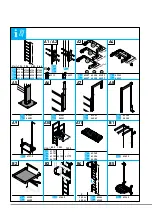

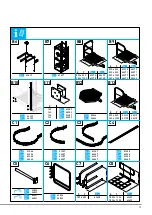

• For a better overview, spread the fixed ladder components out on the ground and

pre-assemble them segment by segment.

4.2.2 Order of installation

As the setup will vary according to specific on-site conditions, there is no prescribed

order of assembly.

Recommendation:

• Carry out installation starting at the top and working towards the bottom.

Observe the prescribed dimensions and spacings.

• The top rung must be flush with the edge of the building or machine.

• The topmost wall bracket should ideally be located in the region of the top two rungs

and should be no lower than between the second and third rung.

• Each ladder section must be attached with two wall brackets or four single wall

brackets. The wall brackets must not be more than 2.0 metres apart.

• The topmost back hoop is attached to the stile extension or the guardrail of

the bridging.

• Wall brackets can be pre-assembled on the supporting structure, following the

planned route of the ladder system. It is essential to ensure flush alignment.

• The platform mounting plates can be pre-assembled for each platform. They must be

assembled flush (both horizontally and vertically).

• Following pre-assembly on the floor, ladder systems (even if they comprise several

ladder segments) can be lifted using lifting tackle of suitable load-bearing capacity.

To prevent damage to the ladder connectors and the overall structure during lifting,

stabilise the ladder system, for example using tensioning straps spanning at least

2 to 3 rungs in the area of the ladder connections. If necessary, reinforce the ladder

system, for example with wood.

• Where necessary, shorten the lower section of the ladder and the ladder safety cage to

suit on-site conditions. Restore anti-corrosion protection.

39

en

Summary of Contents for 41286

Page 61: ...4 3 B2 1 2 13 17 5 Nm 2 2 1 M8 M8 M8x65 2 1 3 17 5 Nm 4 3 B3 1 2 1 3 61...

Page 63: ...4 3 B5 1 2 M8 M8 17 5 Nm M8 M8 13 2x 17 5 Nm 1 1 2 2 4 3 B6 1 2 M8 M8 17 5 Nm 1 2 13 2x A19 63...

Page 64: ...4 3 B7 1 M8 M8 17 5 Nm 2 13 2x...

Page 68: ...4 3 B12 1 2 3 1 2 13 17 5 Nm 0...

Page 72: ...4 3 C8 13 2x 1 2 10x 1 2 3 4 4 3 C7 13 2x 1 2 1 1 2 4 3 17 5 Nm 5 5 6 17 5 Nm...

Page 73: ...4 3 C9 10 73...