10

Inspection steps for components

The centrifugal force weight (4) is not turning:

X

Stop lift movement immediately.

X

Press the EMERGENCY STOP button (2) immediately.

à

The hand lever (1) jumps from position A to

position B.

à

The gripper (6) closes, and lift movement stops.

X

Disconnect the power supply to the winch (7) via the

main switch.

X

Decommission the service lift immediately.

X

Attach a corresponding sign at the main switch of the

service lift.

X

Inform the operator and manufacturer of the service lift.

X

Have the gripper (6) inspected and repaired by

authorised and qualified specialist personnel.

X

Stop lift movement.

à

The brake grips and holds the service lift on the sus-

pension cable.

X

Move the service lift downward.

X

Stop lift movement.

à

The brake grips and holds the service lift on the sus-

pension cable.

The brake does not grip and does not hold the service lift

on the suspension cable:

X

Press the EMERGENCY STOP button (2) immediately.

à

The hand lever (1) jumps from position A to position

B.

à

The gripper (6) closes, and lift movement stops.

X

Disconnect the power supply to the winch (7) via the

main switch.

X

Decommission the service lift immediately.

X

Attach a corresponding sign at the main switch of the

service lift.

X

Inform the operator and manufacturer of the service lift.

X

Have the winch (7) inspected and repaired by authorised

and qualified specialist personnel.

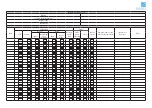

The inspections and results must be documented in the inspection record immediately after the inspection.

X

Tick the "Drive," "Motor brake" and "Centrifugal force weight" fields after the inspection has been carried out.

X

If the inspection failed, tick the "Out of service" field.

X

If all inspections have been completed successfully, tick the "Ready for operation" field.

X

Enter any special items of note in the "Notes" field.

A

B

2.

1.

A

B