4

About these instructions

1

About these instructions

This inspection plan is used for the regular checking of the service lift and is only valid in conjunction with the

original operating instructions. It must be included with every service lift.

Service lifts with Tractel Greifzug components (original operating instructions as old as or older than the revision

from 1 July, 2015) must be provided with this inspection plan and seals immediately and before any further use.

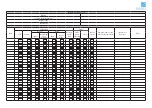

The inspection steps listed in this inspection plan must be carried out and recorded at least once for each day the

service lift is used. The inspection must always be carried out before the first use of the service lift.

The operating instructions and this inspection plan must be followed precisely. Service records must be filled out

without gaps, completely and carefully. Defects must be reported to the operator and the manufacturer of the

service lift immediately. The service information (TBA6000) included with the operating instructions can be used

for this purpose.

Each emergency lowering (see original operating instructions for definition) must be documented specifically in

the inspection plan and reported to the operator and the manufacturer of the service lift. The service information

included with the operating instructions can be used for this purpose. The service lift must be decommissioned

until it has been examined by qualified and trained personnel.

The inspection stickers supplied with this document must be provided with the date of the initial commissioning,

the date of the most recent servicing by qualified and trained personnel and the date of the last inspection by

an expert, all in accordance with the documentation. The inspection stickers must be filled out at the intended

location at the service lift before the lift is operated.

The seals (item number 61875) supplied with this document must be fitted by a person qualified by the operator

and trained by ZARGES in accordance with the instructions in this inspection plan.

1.1 Symbols used

Symbol

Meaning

"Important information"

Information on preventing property damage, fostering understanding or optimising work flows

X

Symbol for an action.

X

If there are multiple steps with actions, follow them in the order presented.

1.2 Structure of warnings

Signal word

Type, source and consequence of the danger

f

Measures for preventing the danger.

2

Safety

If the gripper and winch are not inspected properly, there is a risk of serious injury or death due to falling!

The gripper and winch of the service lift must be fully functional. To ascertain their functionality, all the inspection

steps listed in this inspection plan must be carried out and recorded on a daily basis before the first use of the

service lift.

If one of the inspections fails, the service lift must be decommissioned immediately.

A corresponding sign must be attached at the main switch of the service lift.

Inspection steps to be carried out:

à

Chapter 7 “General inspection steps” on Page 7

à

Chapter 8 “Inspection steps for components” on Page 8

If the gripper and winch are not serviced properly, there is a risk of serious injury or death due to falling!