6

Procedure for triggering the gripper

4

Procedure for triggering the gripper

The gripper may be triggered, in particular with higher towers (hub height over 80 m), if:

à

Lift movement due to the elasticity of the suspension cable while starting or stopping (stop-and-go move-

ment) is incorrectly detected at the safety cable as lift movement at an excessive speed.

In this case, the gripper can be recommissioned. For this purpose:

X

Open the gripper manually or through a short upward movement using the hand crank and the brake venting

lever.

X

Document the catch in the inspection plan.

If an upward movement is not possible (e.g. due to suspension device breakage, lack of traction, damaged sus-

pension cable or similar malfunction causes) or if the gripper is triggered again:

X

Send the gripper to the manufacturer to be examined in accordance with the specifications of the manufactur-

er (see original operating instructions of the service lift and gripper).

X

Do not commission the service lift again until the cause of the fault has been verifiably eliminated.

X

Tick the "Catch" field in the inspection plan, document it separately and inform the operator and manufacturer

of the service lift.

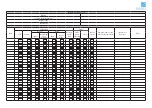

5

Fitting seals

5.1 Seal on the winch

X

Clean the area around the opening for overload

setting with alcohol (or similar).

X

Fit the seal over the opening for overload setting.

5.2 Control box sealing

X

Clean the area with alcohol (or similar).

X

Fit the seal on the control box.