ZPrinter

®

450 Hardware Manual

ZPrinter 450 Overview

3

All Rights Reserved

10/2/07

•

3.2GHz processor or better (recommended)

•

2GB RAM or better (strongly recommended)

•

True Color Graphics

•

64 MB Video Card, or better

•

1024 X 768 pixels, or better

•

16-bit or better with graphics card accelerated for OpenGL

•

1GB free space

•

Ethernet 100/10 Base T

These system configurations may require a higher performance computer based on file size and type.

For more information, please contact your local Reseller, or visit our Website at

www.3dpuser.com

.

1.4 How 3D Printing Works

The 3D Printing System is based on the Massachusetts Institute of Technology's patented 3DP™ Technol-

ogy (3D Printing). The 3D Printing process requires:

•

A 3D Printer

•

Importing a solid 3D modeling file into the ZPrint Software

•

Setting up your files to print in the ZPrint/ZEdit Software

•

Printing, powder removal, and drying the part

•

(Optional) Applying post-processing materials to the printed part

To start, the ZPrint Software takes a three-dimensional design file, (ZPrint is compatible with most 3D mod-

eling software files) and converts it into cross-sections, or layers, that are between 0.0035" - 0.004" (0.089

- 0.102 mm) thick. Before printing, ZPrint evaluates the part geometry and checks if there are enough

materials in the printer to print the number of layers required to build the part. If there are, the printer then

prints each layer, one after the other, from the bottom of the part to the top. If not, ZPrint will prompt you to

add powder, to add binder, or to change a print head before it will start the print job.

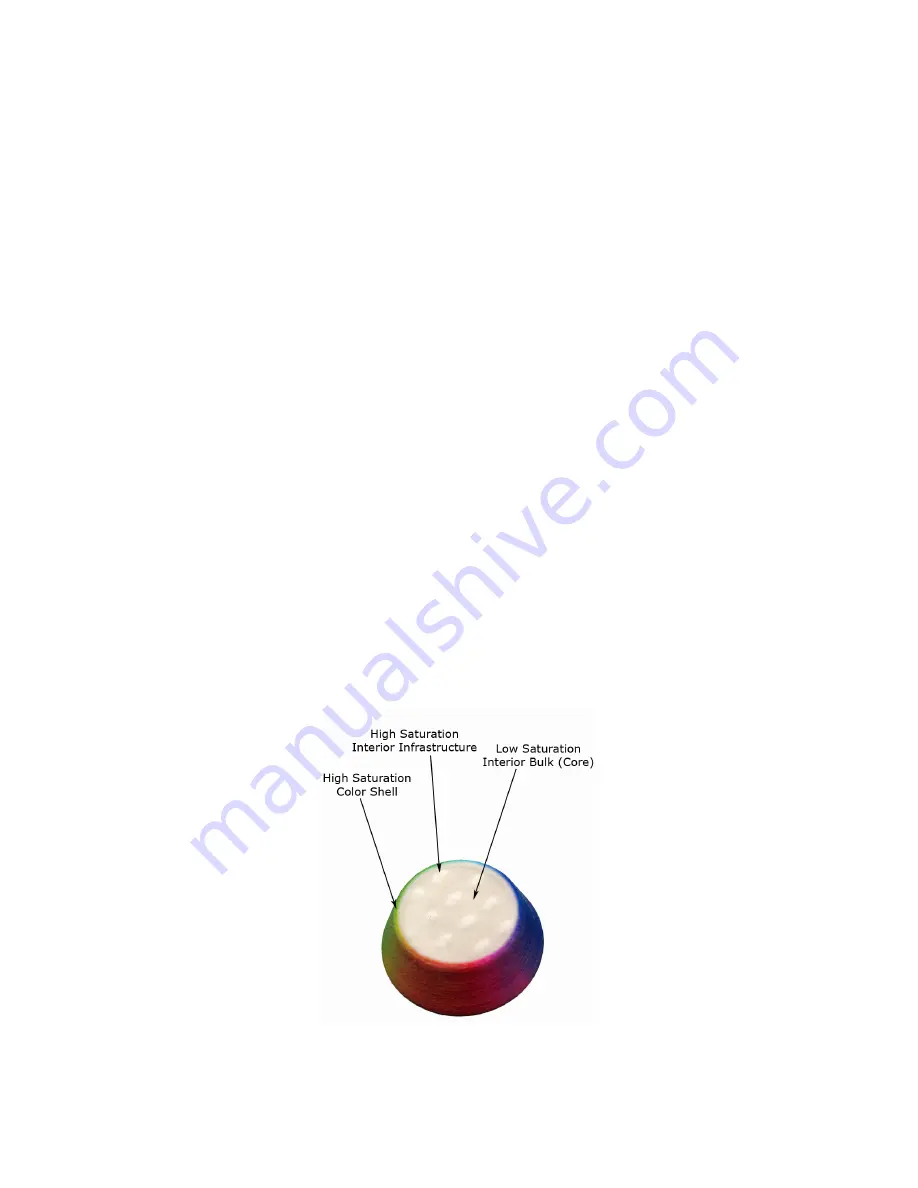

During printing, binder is first applied with a higher saturation to the edges of the part, creating a strong

"shell" for the part exterior. Next, an infrastructure that works like strong scaffolding is created for the part

walls, which are also built with a higher saturation of binder for added strength. The remaining interior

areas are printed with a lower binder saturation, which gives the part its stability.

When the part is finished printing, the printer heats up to the appropriate temperature and dries the part

while it is still in the Build Bed surrounded by powder. When the drying cycle is finished, an automatic pow-