ZPrinter

®

450 Hardware Manual

ZPrinter 450 Overview

4

All Rights Reserved

10/2/07

der removal cycle empties the Build Bed of most of the excess powder around the part, and returns that

powder to the Feeder for reuse. After the bulk of the powder removed, the part is moved from the Build

Bed to the integrated Fine-Powder Removal Chamber where any remaining powder is cleaned off the part.

After the part is powder-free, it is ready to be removed from the printer. You can evaluate the part as it is, or

you can choose to post-process the part with infiltration products to give it additional strength, durability,

and color vibrancy. With the finished part in your hands, you can start improving or modifying your design

within the same day, and usually within hours.

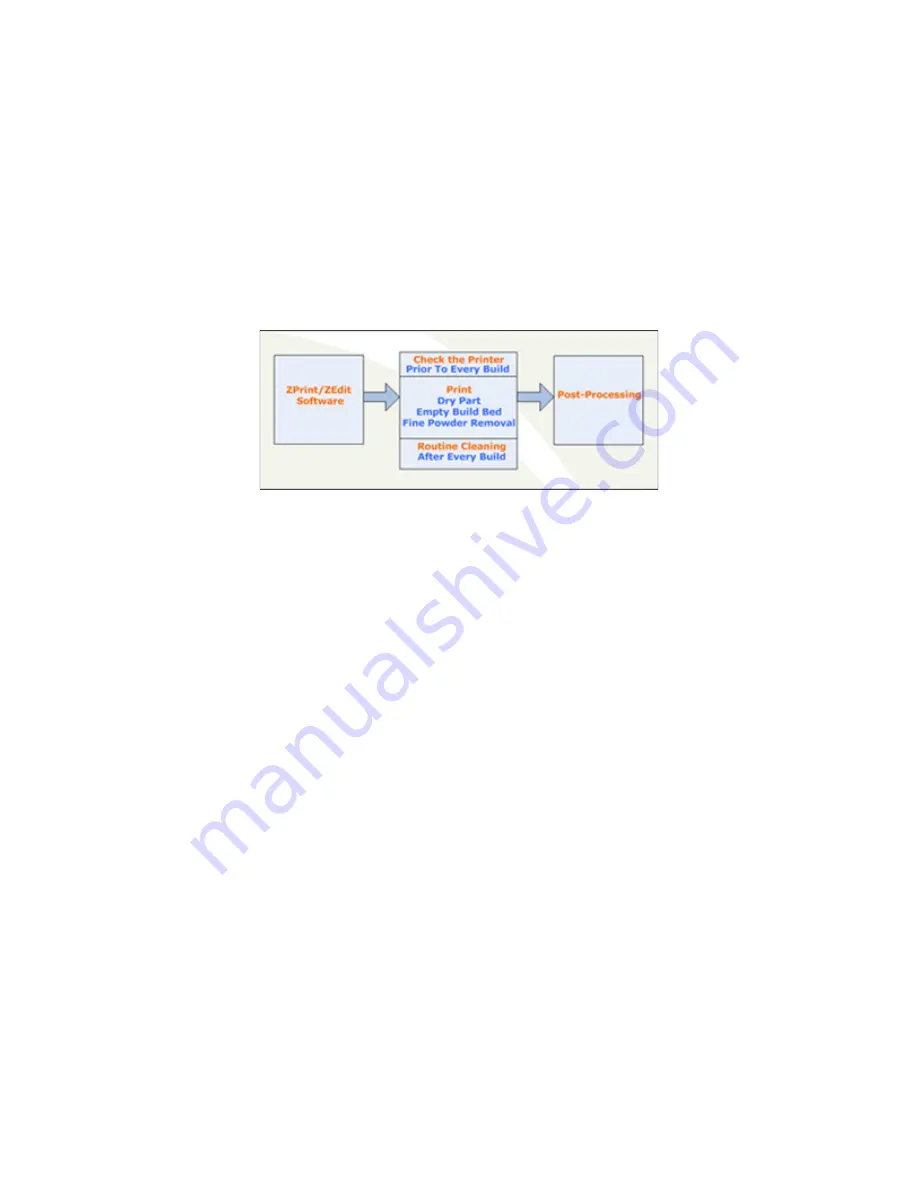

1.5 3D Printing Process Diagram

1.6 Important Terms

Air Wand

- The tool located in the Fine-Powder Removal Chamber that supplies air pressure. Use this tool

to remove all remaining powder from a part after the initial (automatic or manual) powder removal.

Alignment Sensor Window

- Located on the underside of the Carriage unit. Wipe powder off of the Align-

ment Sensor Window every time you replace a print head, or whenever you remove a print head to clean

the contacts.

Binder

- Solution that is dispensed through the HP11 print head and applied to the powder. The binder sat-

uration value will vary depending on the part geometry. The ZPrint software uses a default core and shell

saturation value that is suitable for most part geometries.

Build Bed

- The 8” x 10” x 8” area in front of the Feeder where the part is printed. The platform of the Build

Bed can be raised or lowered using the appropriate command on the printer LCD menu. Before each build,

the printer fills the Build Bed with powder and then spreads a layer of powder to ensure the surface of the

Build Bed is completely smooth.

Build Chamber

- The left, interior side of the printer that houses the Build Bed, Service Station, Parking

Caps, the Debris Filter, the Carriage, the Gantry assembly, the Vacuum Hose, the Heater Vent, and the

Feeder.

Carriage

- Assembly that houses the Print Heads, Pogo Pin Connectors, and the Alignment Sensor Win-

dow.

Consumables

- Powder-Binder-Infiltrant products that are available in a variety of systems for all of your

color or monochrome modeling needs. All consumables have been developed for the fastest printing

speeds and lowest materials costs.