6.TROUBLESHOOTING

Use the table below to troubleshoot problems before contacting service

personal or your local dealer. If the probem continues after troubleshooting,

call your local dealer for istance.

Follow all safety precautions whenever diagnosing or servicing the tool

Disconnect power supply before service.

14

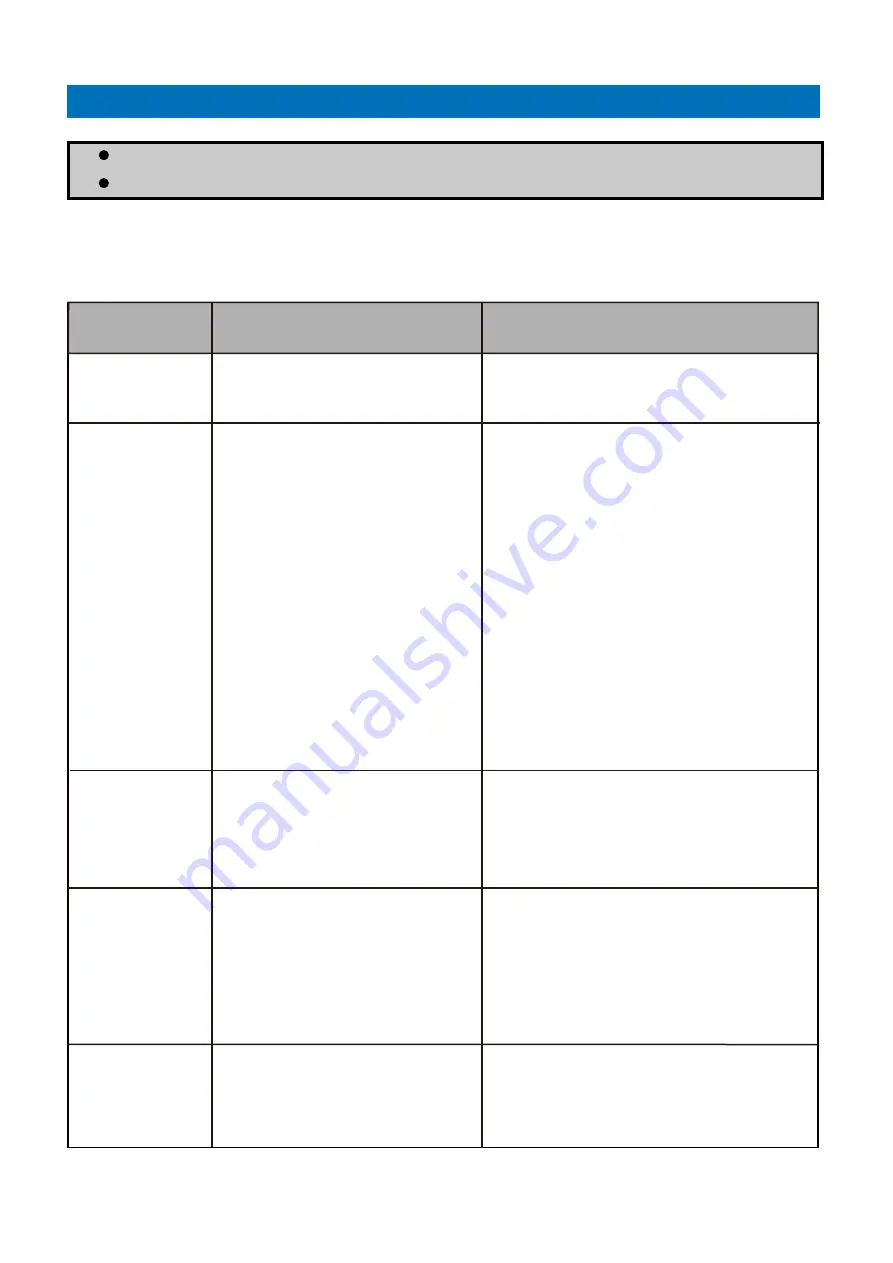

Failure

Possible Cause

Corrective Action

Motor overheats

1.Incorrect power cords

2.Winch is running too long

1.Use only supplied power cords

2.Allow winch to cool down periodically

Motor does

not turn on

1.Remote battery is dead

2.Loose battery cable connec-

tions

3.Vehicle battery needs charging

4.Solenoid is malfunctioning

5.Remote damaged

6.Defective motor

7.water has entered motor

8.Internal damage or wear

1.Replace remote battery

2.Tighten nuts on all cable connections

3.Fully charge battery

4.Tap solenoid to loosen

contacts. Apply 12 volts to coil

terminals directly. A clicking

indicates proper activation

5.Replace remote

6.Check for voltage at armature port with

switch pressed. If voltage is

present, replace motor

7.Allow to drain and dry. Run in

short bursts without load until

completely dry

8.Have technician service winch

Motor runs but

wire rope

drum does not

run

Clutch not engaged

Move the clutch handle to the

engaged position. If problem persists,

a qualified technician needs to check

and repair

Motor runs

slowly or

without normal

power

1.Insufficient current or

voltage

2.Loose or corroded battery

cable connections

3.Incorrect power cords

1.Battery weak, recharge it. Run

winch with vehicle motor running

2.Clean, tighten, or replace

3.Use only supplied power cords

Motor runs in

one direction only

1.Defective or stuck solenoid

2.Remote damaged

1.Tap solenoid to loosen contacts Repair

or replace solenoid

2.Replace remote

Summary of Contents for 2500LB

Page 1: ...ZEAK 2500LB WINCH ...