20 - EN

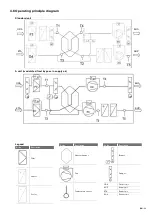

Assign the second connected digital input of the

3 Position switch to option 2 “Ventilation speed

2” (in the case of the schematic displayed in the

installation chapter this is digital input 5).

Assign the third connected digital input of the 3

Position switch to option 1 “Ventilation speed 1”

(in the case of the schematic displayed in the

installation chapter this is digital input 6).

SAG 0-M (M09 option 3)

When a “SAG 0-M” switch is

present, the switch must be

assigned in parameter M09 to the

“Proportional ventilation” function.

Check which analog input the

switch is connected to and choose

option 3 for that analog input/switch.

When the switch is fully opened (10V) the unit will run

on the set air volume of ventilation speed 4. When

the switch is fully closed (0V) the fans of the unit will

turn off.

6.6 Sensor (0..10V) control

(M02-10 M04-11,

M09)

When using a sensor to control the ventilation, the

unit must be set to option 3 “0..10V (positive)” or

option 4 “0..10V (negative)” in M02-10. (see chapter

“Air volume control” to learn the difference between

positive and negative control)

Each connected sensor must be assigned in

parameter M09 to the correct “air flow” function.

Check the location of sensor connected and to

which analog input the sensor is connected and

choose option 8 for a supply sensor or option 9 for

an exhaust sensor for that analog input/sensor.

The preset value of the desired setpoint can be

changed in parameter M02-15 (supply air) and/or

M02-16 (exhaust air).

Only one sensor present (M04-11)

When only one sensor is present, an air ratio factor

must also be set in parameter M04-11.

6.7 Constant pressure control

(M02-10,

M04-11, M09)

When using a pressure sensor to control the

ventilation, the unit must be set to option 1

“Constant Pressure (positive)” or option 2 “Constant

Pressure (negative)” in M02-10. (see chapter “Air

volume control” to learn the difference between

positive and negative control)

Each connected pressure sensor must be assigned

in parameter M09 to the correct “air pressure”

function. Check the type of sensor connected and

to which analog input the sensor is connected and

choose the correct option for that analog input/

sensor.

Pressure functions in M09

Option

0..500Pa supply

4

0..500Pa exhaust

5

0..300Pa supply

6

0..300Pa exhaust

7

The preset value of the desired pressure setpoint

can be changed in parameter M02-11 (supply air)

and/or M02-12 (exhaust air).

Only one sensor present (M04-11)

When only one pressure sensor is present, an air

ratio factor must also be set in parameter M04-11.

6.8 Switch to second setpoint

(M02, M05

option 25)

When a switch is present to switch to a second

setpoint, the switch must be assigned in parameter

M05 to the “Second setpoint select” function. Check

which digital input the switch is connected to and

choose option 25 for that digital input/switch.

Constant pressure control (M02-13, M02-14)

When the ventilation setting of the unit is controlled

by one or more pressure sensors the preset value

of the desired second setpoint can be changed

in parameter M02-13 (supply air) and/or M02-14

(exhaust air).

Sensor (0..10V) control (M02-17, M02-18)

When the ventilation setting of the unit is controlled

by one or more sensors , the preset value of

the desired second setpoint can be changed in

parameter M02-17 (supply air) and/or M02-18

(exhaust air).

Summary of Contents for ComfoAir 1500

Page 1: ...ComfoAir XL ComfoAir Eco Manual Cooling Fresh Air Clean Air Heating...

Page 45: ...EN 45...

Page 46: ...46 EN...

Page 47: ...EN 47...