17 - EN

hot water (max. 40 °C).

b. Rinse the heat exchanger with clean hot tap wa-

ter (max. 40 °C).

c. Clasp the heat exchanger between both hands

(on the coloured side surfaces) and shake the

water from the heat exchanger.

Only an enthalpy exchanger with a blue co-

ver can be washed with water. When having

an enthalpy exchanger with a white cover

never wash it with water.

Do not use aggressive cleaning agents or

solvents.

If the fans or preheater element filter also

need maintenance do not re-install the heat

exchanger yet.

10.

If no more maintenance is necessary install

all parts in reverse order, reconnect the pow-

er and carry out the self-test in accordance

with menu P76

.

Fasten the screws to a maximum of 1.5 Nm.

This is roughly equal to setting 2 of an ave-

rage battery-powered drill.

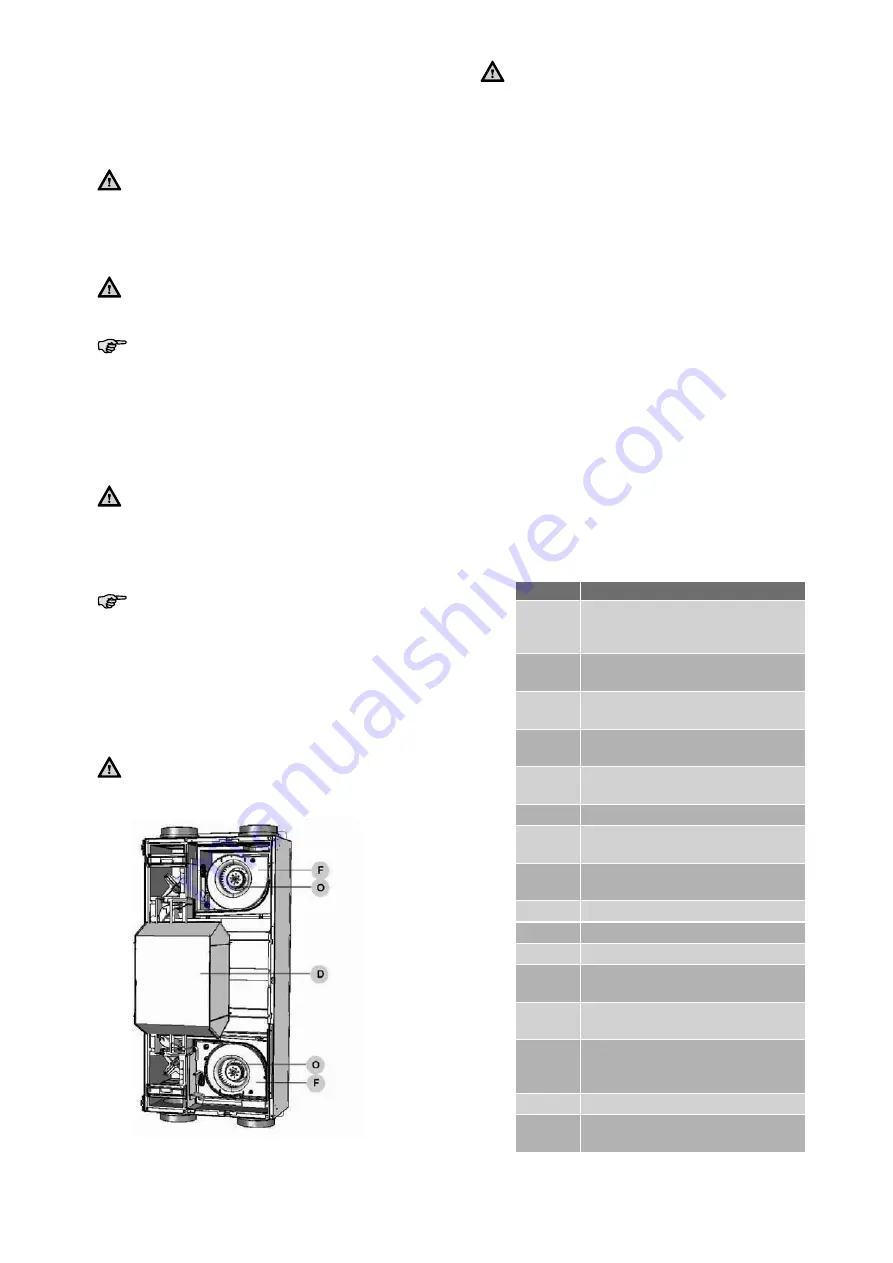

2.9.2 Inspecting and cleaning the fans

Check the fans once every 2 years.

1. Remove the heat exchanger as instructed in the

maintenance chapter of the heat exchanger

2.

Remove

the inflow nozzle (F) by unscrewing the

2 screws surrounding the scroll casing.

3. Inspecting and if necessary clean the fans (O).

- Use a soft brush to clean the fan impellers.

- Use a vacuum cleaner to remove dust.

Do not damage the fan impellers or tempe-

rature sensor.

4.

Install

all parts in reverse order.

5.

Carry out

the self-test in accordance with menu

P76.

Fasten the screws to a maximum of 1.5 Nm.

This is roughly equal to setting 2 of an ave-

rage battery-powered drill.

2.10 Malfunctions

Malfunctions in the ComfoAir are reported as follows:

■

The malfunction alert appears on the ComfoS-

ense panel;

■

The malfunction alert appears on the display;

■

The malfunction indicator on the 3-position

switch lights up.

Malfunction alerts may not appear on the digital oper-

ating device in all cases, even though there is a mal-

function (or problem). A concise explanation of both

types of malfunction (or problem) is given in the fol-

lowing paragraphs.

2.10.1 Malfunction alerts on the digital

operating device

In the event of a malfunction, the corresponding mal-

function code will be displayed on the digital operat-

ing device of the ComfoAir.

Below is a list of the malfunction alerts on the digital

operating device.

In the chapter about troubleshooting is explained

how to solve these malfunctions

Code

Description

A0

NTC sensor TGe is defective.

(= geothermal heat exchanger tem-

perature)

A1

NTC sensor T1 is defective.

(= outside air temperature)

A2

NTC sensor T2 is defective.

(= supply air temperature)

A3

NTC sensor T3 is defective.

( =return air temperature)

A4

NTC sensor T4 is defective.

(= exhaust air temperature)

A5

Malfunction in the bypass motor.

A6

Malfunction in the

Pre heater motor.

A7

Pre heater does not heat suffi-

ciently.

A8

Pre heater becomes too hot

E1

Exhaust fan not rotating.

E2

Supply fan not rotating.

EA1

Enthalpy sensor measures exces-

sive Relative Humidity (RH) values.

EA2

No communication between the

enthalpy sensor and the ComfoAir.

COMM

ERROR

No communication between the

ComfoSense panel and the Com-

foAir.

FLTR

Internal Filter is dirty.

FLTR

EXT

External Filter is dirty.