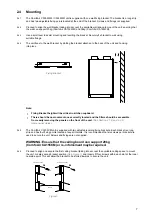

2.9 Wiring The Unit

Step 1

Undo four screws from electrical connection cover and remove

ComfoAir CA155WM

ComfoAir CA185WM

ComfoAir CA155CM

HR155WM

HR185WM

HR155CM

Figure 14 - Top View

Figure 15 - Top View

Figure 16 - Top View

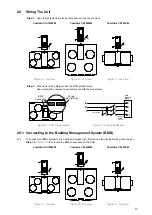

Step 2

Wire as per wiring diagram into the PCB terminal block.

Upon completion, replace cover and secure with the four screws.

PCB CLOSEUP

BMS

Connection

Wiring

Terminal block

Wiring

E

N

N

L

L

L1

PCB

Terminal

Block

Triple-pole

Isolating

Switch

E

Light Switch

Light

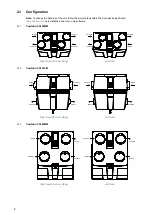

Figure 17 - PCB Terminal Block

Figure 18 - Wiring Specification

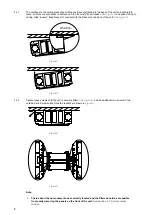

2.9.1 Connecting to the Building Management System (BMS)

2.9.2

To connect your BMS system to the ComfoAir Compact unit, first remove the electrical wiring cover as per

Step 1

in

Section 2.9

, then locate the BMS connections on the PCB.

ComfoAir CA155WM

ComfoAir CA185WM

ComfoAir CA155CM

HR155WM

HR185WM

HR155CM

Figure 19 - Top View

Figure 20 - Top View

Figure 21 - Top View

13