28 - EN

EN - 29

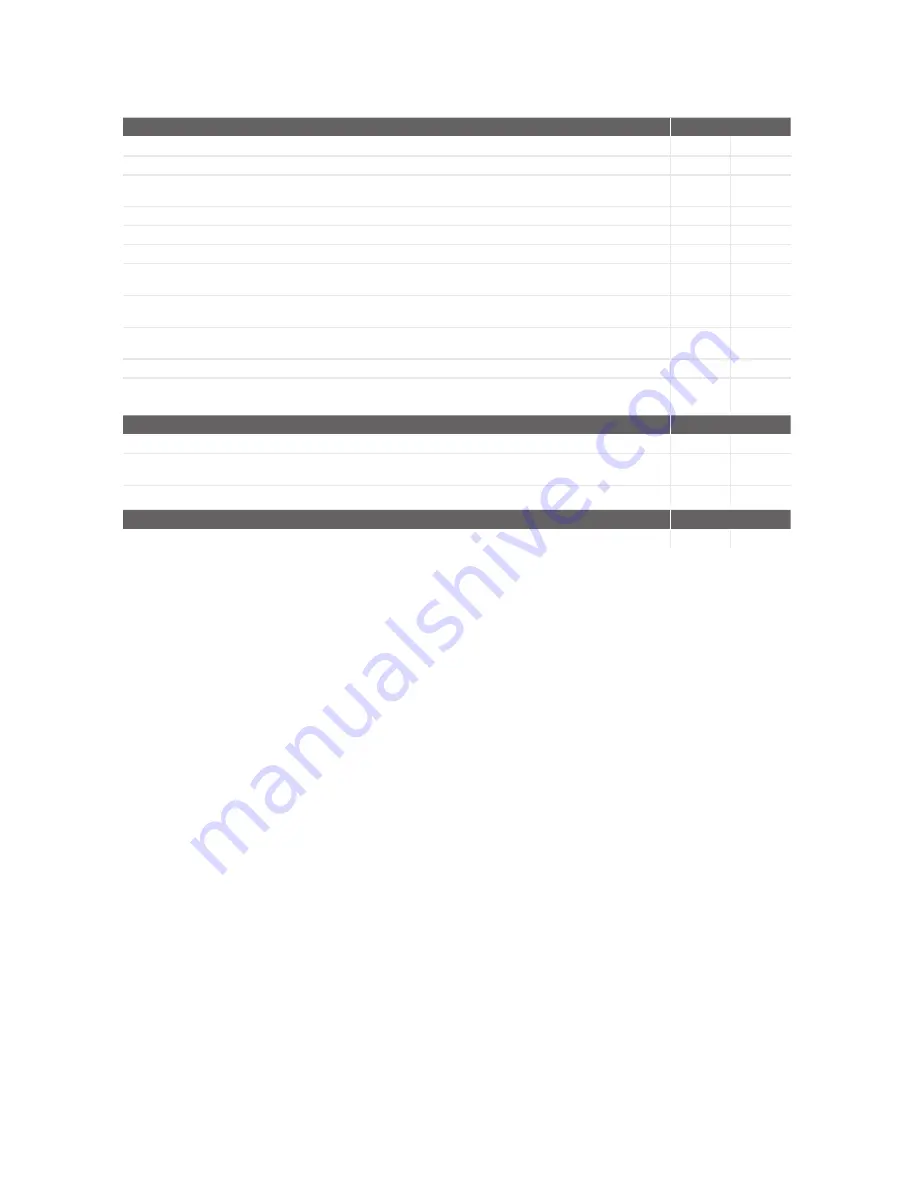

Part 2b - Inspection of installation

This section should be completed by the commissioning engineer prior to completing Part 3.

2.3a Visual inspections - General (all systems)

Total installed equivalent area of background ventilators in dwelling

mm

Total floor area of dwelling

m2

Does the total installed equivalent ventilator area meet the requirements given in

tables 5.2a, 5.2b, or 5.2c in ADF?

Yes

No

Have all background ventilators been left in the open position?

Yes

No

Have the correct number and location of extract fans/terminals been installed that satisfies table 5.2a in ADF?

Yes

No

Is the installation complete with no obvious defects present?

Yes

No

Do all internal doors have sufficient undercut to allow air transfer between rooms

(i.e. 10 mm over and above final floor finish)

Yes

No

Has all protection/packaging been removed (including background ventilators)

such that system is fully functional?

Yes

No

For ducted systems, has the ductwork installation been installed in such manner that air resistance and

leakage is kept to a minimum?

Yes

No

Are the correct number and size of background ventilators provided that satisfy ADF?

Yes

No

Has the entire system been installed such that there is sufficient access for routine maintenance and

repair/replacement of components?

Yes

No

2.3a Visual inspections - General (systems 3 and 4 only)

Have appropriate air terminal devices been installed to allow system balance?

Yes

No

Has the heat recovery unit (System 4 only) and all ductwork been effectively insulated where

installed in unheated spaces?

Yes

No

Condensation connection is complete and drains to an appropriate location (System 4 only)?

Yes

No

2.3c Other inspections - General (systems 1, 3 and 4 only)

Upon initial start up, was any abnormal sound or vibration experiences, or unusual smells detected?

Yes

No

Summary of Contents for ComfoAir Q 350 ST

Page 1: ...Cooling Fresh Air Clean Air Heating Ventilation system Zehnder ComfoAir Q User manual ...

Page 4: ...4 EN ...

Page 33: ...EN 33 Data Activity Initials ...

Page 34: ......

Page 35: ......