2 - EN

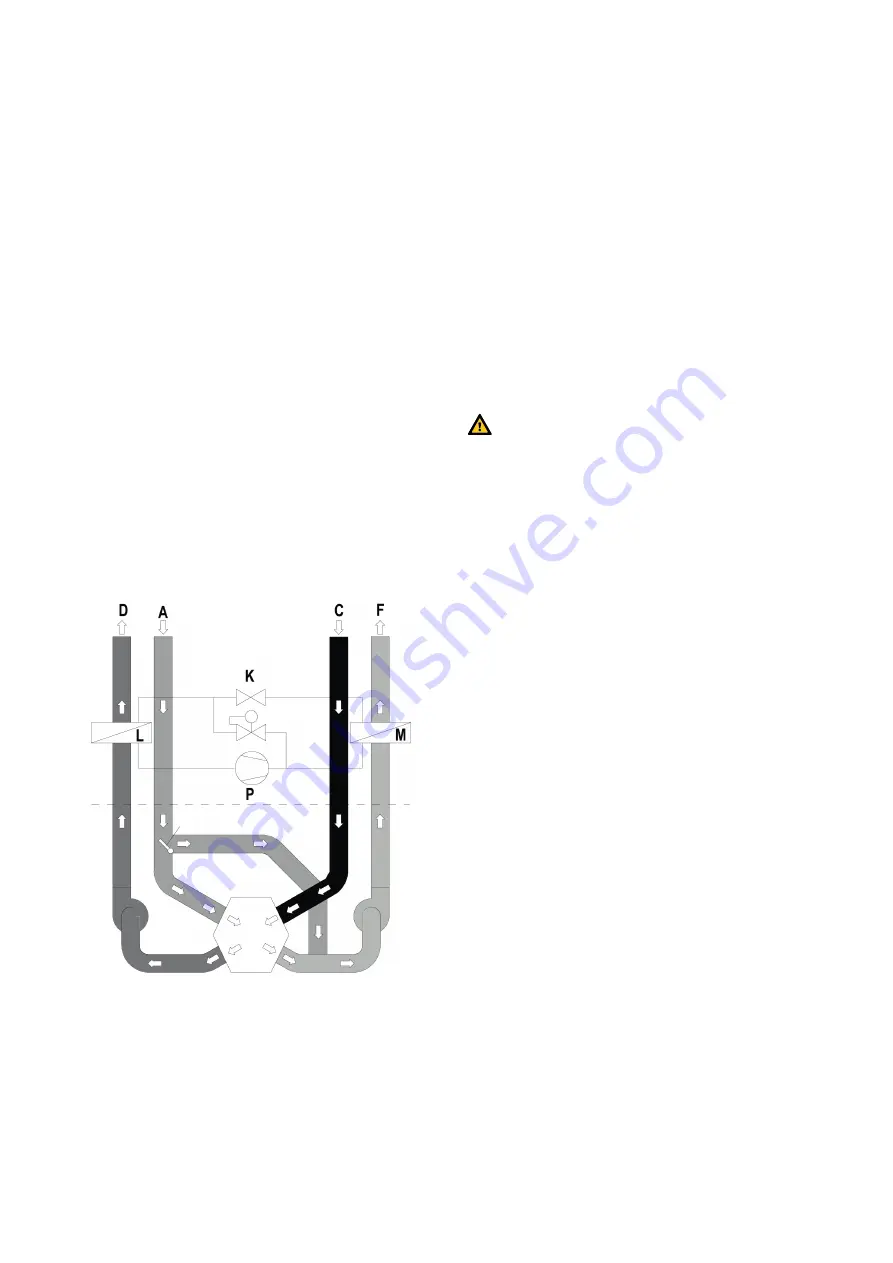

3 Summary and principle

Read this chapter if your are interested in how the Comfo-

Cool works.

The ComfoCool is equipped with a compression cooling

system, as is used in fridges. The electrically driven com-

pressor

(P)

pumps coolant round the condenser

(M)

, the

capillary

(K)

and the evaporator

(L)

in that order.

In the condenser

(M)

the coolant is converted from a gas to

a liquid (condensation). This process releases energy that is

discharged in the air extracted from the dwelling.

The capillary

(K)

ensures reduced pressure in the cool-

ant, making it boil. This is the opposite effect of a pressure

cooker, which raises boiling point by increasing pressure.

In the evaporator

(L)

the coolant converts from liquid to

vapour. This phased process requires energy, which is

extracted from the supply air

(D)

. This cools the supply air.

The fins of the evaporator

(L)

are colder than the air that

passes them. This creates condensate, dehumidifying the

air. The condensate is drained to the waste-water system.

The result is that energy is transferred from the supply air

(D)

(which becomes cooler and drier as a result) to the

exhaust air

(F)

(which heats up as a result). The combina-

tion of ComfoCool and heat-recovery unit cools more effi-

ciently, as the heat-recovery unit then behaves more like a

“cold-recovery unit” in warm weather. Warm fresh air is pre-

cooled by the heat-recovery unit and is then cooled further

by the ComfoCool.

4 Installation

4.1. Installation conditions

In order to determine whether the ComfoCool can be

installed in a certain area, the following aspects must be

taken into account:

General

• The ComfoCool must be installed according to the gen-

eral and locally applicable safety and installation regu-

lations of power and water companies, as well as the

instructions in this manual.

• The ComfoCool must be installed in a frost-free space

with climate zone N (16-32°C).

• The heat-recovery unit should be mounted on a support

frame (see under service parts), which should stand on

a stable floor. The ComfoCool is placed on an adaptor

set which is then mounted on the heat-recovery unit.

Fitting to a heat-recovery unit mounted on a wall is

NOT permitted for safety reasons.

• The ComfoCool is fitted with fall protection, which

should be firmly attached to the wall.

• The following must be available: Ø180mm air duct con-

nections, 230V electrical connection with sufficient

capacity, and facilities for condensation drainage.

• The roof vents should be made airtight and damp-

proof.

•

ATTENTION: All supply and exhaust ducts should be

damp-proofed.

This prevents condensation forming on

the inner or outer duct surface and improves cooling

efficiency.

• The exhaust duct should drain in the direction of the

unit.

• The condensation must be drained off frost-free, at a

gradient and incorporate a ‘U’ bend.

• DO NOT connect a powered extractor hood to this sys-

tem.

• We recommend fitting the ComfoCool with silencers

right up to the unit, on both the supply and return pipes.

For more information, please contact Zehnder.

• The place of installation must be chosen so that there

is sufficient room around the unit for air duct connec-

tions, intake and exhaust piping and in order to carry

out installation work. Keep at least 1 metre free in front

of the unit. At least 250mm should be kept free at the

side with the condensation drain.

ComfoAir 350 Luxe

• The height when mounted should be at least 185cm,

beyond the space required for the duct connection.

ComfoAir 550 Luxe

• The height when mounted should be at least 173cm,

beyond the space required for the duct connection.

A 10mm gap should be left under the inside doors in order

to ensure effective and draught-free airflow in the house. If

these openings are obstructed, due to draught excluders

or deep-pile carpet, the airflow in the house will stagnate.

As a result, system performance will be compromised or

fail altogether.