10

1.

General

1.1

Application

This operating instruction is valid for the jet pump MP, the booster set MPD and the booster kit HMP

.

Non-compliance with the operating instructions - in particular with the safety instructions - as well as non-manufacturer modification or use

of non-original spare parts will result in loss of guarantee coverage. The manufacturer accepts no liability for damage or injury resulting from

incorrect use of the equipment.

This product may also pass as any other electrical equipment in cause of lacking electrical supply. If you may get any damages thereby,

please calculate in accordance to the use an emergency power generator, a second pump and/ or a network independent alarm system. As the

manufacturer we will be after the buying at your disposal for near information. In cause of defects or damages please contact your retail

trader.

Manufacturer

:

ZEHNDER Pumpen GmbH

Zwönitzer Straße 19

08344 Grünhain-Beierfeld

MP 155

MPD 350

HMP 350

Product variations

MP 255

MPD 450

HMP 450

Instruction last modified

:

December

2018

1.2

Queries and Ordering

For queries and orders, please contact your authorized retail trader.

1.3

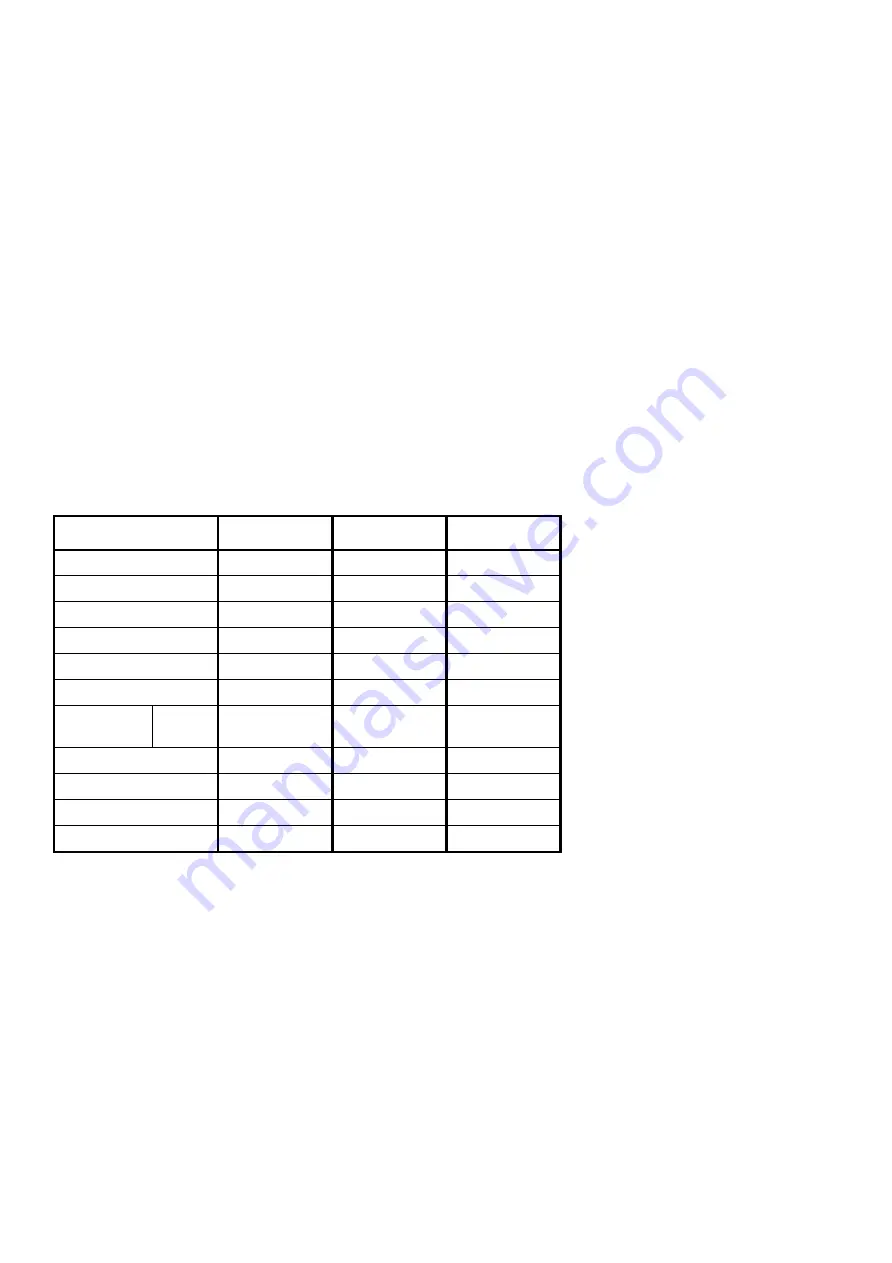

Technical data:

MP/HMP/MPD

350

MP/HMP/MPD

450

MP 450

Three-phase

Power P1

1,0 kW

1,7 kW

1,5 kW

Power P2

0,7 kW

1,3 kW

1,3 kW

Voltage

230 V 50 Hz

230 V 50 Hz

230/400 V 50 Hz

Nominal current

4,4 A

7,4 A

5,4/3,1 A

max. capacity

4,3 m³/h

6,0 m³/h

6,0 m³/h

max. head

44 m

50 m

50 m

max. Final

pressure

With pre-pressure

from the suction

side

60 m / 6 bar

60 m / 6 bar

60 m / 6 bar

Sucking to max.

8,5 m

8,5 m

8,5 m

Pressure line

1“

1“

1“

Pressure inflow

1“

1“

1“

Weight

9,5/13,5

11,0/15,0 kg

11,0 kg

The pumps at series MP, MPD and HMP are applicable to a liquid temperature of max. 40° C.

Materials:

Pump housing:

Impeller:

Motor shaft:

Screws:

Seals:

Stainless steel

Polyphenilenoxyd (PPO-GF)

Stainless steel

Stainless steel

NBR

Mechanical seal: Carbon/ceramic/NBR/ stainless steel

Diaphragm vessel: powder coated steel (HMP) resp. stainless steel (HMP- E), wear resistant butyl-membrane (HMP-P)

1.4

Areas of application

The pumps will be used to deliver clean water out of wells, creeks and tanks for irrigation, domestic water supply, etc. The pumps are

designed for pumping thin, clean, non-explosive liquids, not containing solid particles or fibres. The temperature of the pump liquid must not

exceed 40°C.

Sand and other abrasive parts may damage the seals or other parts of the pump (use a pre-filter).