15

Commercial water loop

Commercial systems typically

include a number of units

connected to a common piping

system. Any unit plumbing

maintenance work can

introduce air into the piping

system; therefore air elimination

equipment is a major component

of the mechanical room

plumbing. Consideration should

be given to insulating the piping

surfaces to avoid condensation.

Zehnder Rittling recommends

unit insulation any time the water

temperature is expected to be

below 60 ºF (15.6 ºC). Metal-to-

plastic threaded joints should

never be used due to their

tendency to leak over time.

Piping installation

Teflon

®

tape thread sealant

is recommended to minimize

internal fouling of the heat

exchanger. Do not over tighten

connections and route piping so

as not to interfere with service or

maintenance access. Depending

upon selection, hose kits may

include shut-off valves, P/T plugs

for performance measurement,

high pressure stainless steel

braided hose, “Y” type strainer

with blow down valve, balancing

valve, and/or “J” type swivel

connection. Balancing valves and

an external low pressure drop

solenoid valve for use in variable

speed pumping systems may

also be included in the hose kit.

The piping system should

be flushed to remove dirt,

piping chips, and other foreign

material prior to operation

(see “Piping System Cleaning

and Flushing Procedures” in

this manual). The flow rate is

usually set between 2.25 and

3.5 gpm per ton (2.9 and 4.5

l/m per kW) of cooling capacity.

Zehnder Rittling recommends

3.3 gpm per ton (4.3 l/m per

kW) for most applications of

water loop heat pumps. To

ensure proper maintenance

and servicing, P/T ports are

imperative for temperature and

flow verification, as well as

performance checks.

Loop conditions

Water loop heat pump (cooling

tower/boiler) systems typically

utilize a common loop,

maintained between 60-90 °F

(16-32 °C). The use of a closed

circuit evaporative cooling tower

with a secondary heat exchanger

between the tower and the

water loop is recommended. If an

open type cooling tower is used

continuously, chemical treatment

and filtering will be necessary. For

low entering water temperature

applications, Zehnder Rittling

recommends following the water

limit guidelines:

Table 1:

Water limit guidelines

EWT

min.

(°F)

Min. flow

rate

(GPM/ton)

Antifreeze

required?

50

1.5

No

40-50

3

No

40-50

1.5

Yes

20-40

3

Yes

Low water temperature

cutout setting

Zehnder Rittling’s heat pump

controller includes a user

configurable switch (DIP switch 2

on the PCB controller) to change

the low water temperature cutout

(FP1) setting between water

(30 °F) and Glycol (10 °F). When

loop conditions allow (antifreeze is

used), the FP1 DIP switch should

be set to the Glycol (10 °F) setting

to avoid nuisance faults.

Water loop

applications

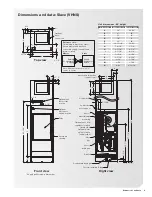

Applications