Unit and system checkout: Before powering

Unit checkout

■

■

Filter

Clean or replace filter, if

required.

■

■

Balancing/shut-off valves

Ensure that all isolation valves

are open and water control

valves are wired.

■

■

P-trap connections

Ensure all condensate P-trap

connections are secure.

Failure to do so could cause

extensive damage to drywall

and flooring.

■

■

Drain pan

Ensure drain hose from air coil

is properly positioned over

drain pan. Failure to do so

could cause extensive damage

to drywall and flooring.

■

■

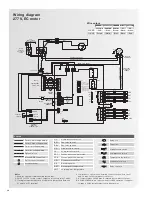

Line voltage and wiring

Verify that voltage is within an

acceptable range for the unit.

Verify wiring and fuses/breakers

are properly sized. Verify that

low voltage wiring is complete.

■

■

Unit controls

Verify that the microprocessor

dip switches are set for

proper operation and system

configuration and the thermostat

is properly configured.

■

■

Entering water and air

Ensure that entering water and

air temperatures are within

operating limits of Tables 12

and 13.

■

■

Unit fan

Manually rotate fan to verify

free rotation and ensure that

blower wheel is secured to

the motor shaft. Be sure to

remove any shipping supports

if needed. Do not oil motors

upon start-up. Fan motors are

permanently lubricated from

the factory. Check unit fan

speed selection and compare

to design requirements.

■

■

Condensate line

Verify that condensate line is open

and properly pitched toward drain.

■

■

Water flow balancing

Record inlet and outlet water

temperatures for each heat pump

upon startup. This check can

eliminate nuisance lock outs and

high velocity water flow that could

erode heat exchangers.

System checkout

■

■

System water temperature

Check water temperature for

proper range and also verify

heating and cooling set points for

proper operation.

■

■

System pH

Check & adjust water pH if necessary

to maintain levels indicated in

Table 5. Proper pH promotes

longevity of hoses & fittings.

■

■

System flushing

Verify that all hoses are connected

end to end when flushing to ensure

that debris bypasses the unit heat

exchanger, water valves and other

components. Water used in the

system must be potable quality

initially and clean of dirt, piping

slag and strong chemical cleaning

agents. Verify that all air is purged

from the system. Air in the system

can cause poor operation and/or

system corrosion.

■

■

Cooling tower/boiler

Check equipment for proper set

points and operation.

■

■

Standby pumps

Verify that the standby pump is

properly installed and in operating

condition.

■

■

System controls

Verify that system controls

function and operate in the proper

sequence.

■

■

Low water temperature cut-out

Verify that low water

temperature cut-out controls

are provided for the outdoor

portion of the loop. Otherwise,

operating problems may occur.

n

System control center

If applicable, verify that the

control center and alarm panel

have appropriate set points

and are operating as designed.

Verify that ALL water control

valves are open and allow

water flow prior to engaging the

compressor. Freezing of the coax

or water lines can permanently

damage the heat pump.

To avoid equipment damage,

DO NOT leave system filled in

a building without heat during

the winter unless antifreeze is

added to the water loop. Heat

exchangers never fully drain by

themselves and will freeze unless

winterized with antifreeze.

47

Start-up