7

After making welding seam move the

electrode back. This is necessary for

filling the welding crater.

DanGerous factors when

performinG welDinG

operations

Fire prevention

• All inflammable materials should be

removed from the welding area.

• Do not strike the arc on a gas tank or

near it.

• Never attempt to weld fuel tanks or

tanks filled with gas unless all measures

are taken to guarantee that they contain

no fumes.

• Before welding fuel tanks they must be

thoroughly cleaned with steam.

Welding fumes

When welding, toxic fumes are emitted.

Always work in well ventilated areas.

Electric arc light

Always use protecting mask or welding

helmet, equipped with corresponding

glass filter. Never use damaged safety

equipment.

High temperature

Use protective gloves. They provide

hands protection from ultra-violet light

and heat, emitted by electric arc. It is

recommended to wear special clothing.

aDDitional protective

cloths

When welding with heavy current use

protecting apron, which will protect you

from spatter.

When performing overhead welding use

adequate head wear, which will protect

your head and neck.

It is recommended to wear closed safety

boots with steel toe caps.

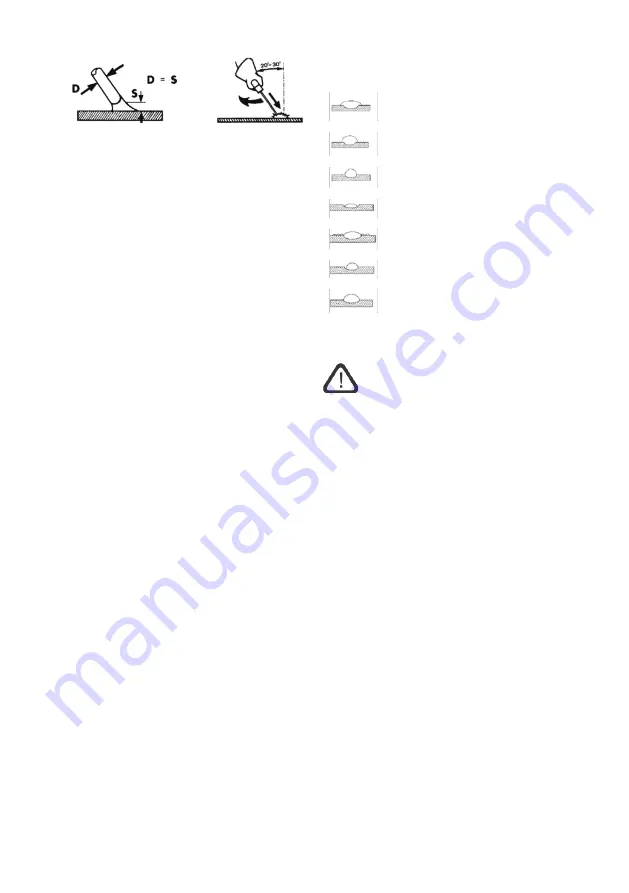

welDinG seam specifications

Electrode movement is too slow

Very short arc

Very low welding current

Electrode movement is too fast

Very long arc

Very high welding current

Normal seam

maintenance

WARNING! Before disassembling

any panel of the machine for performing

any operations inside disconnect the plug

from the receptacle.

Regularly, depending on usage in dusty

environment, perform maintenance of

the machine internals. Remove dust from

internal components of the machine with

low pressure air flow.

After maintenance reinstall panels and

tighten screws.

Never perform welding when the

machine is open!

troubleshootinG

Before contacting service center

for technical assistance perform the

following checks:

• Ensure the welding current regulated by

potentiometer corresponds the diameter

and type of the used electrode.

• Power indicator (On) shall not lit when

there is power failure (check cables,

outputs, fumes etc.).

• Yellow indicator shows overheating,

short circuit, too low or too high voltage.

• Check voltage of the power line.