Page 6 of 12

Zenith Autoboil - Installation & Operating Instructions - 81433 - June 2012 v1.01

Step 3 – Connecting

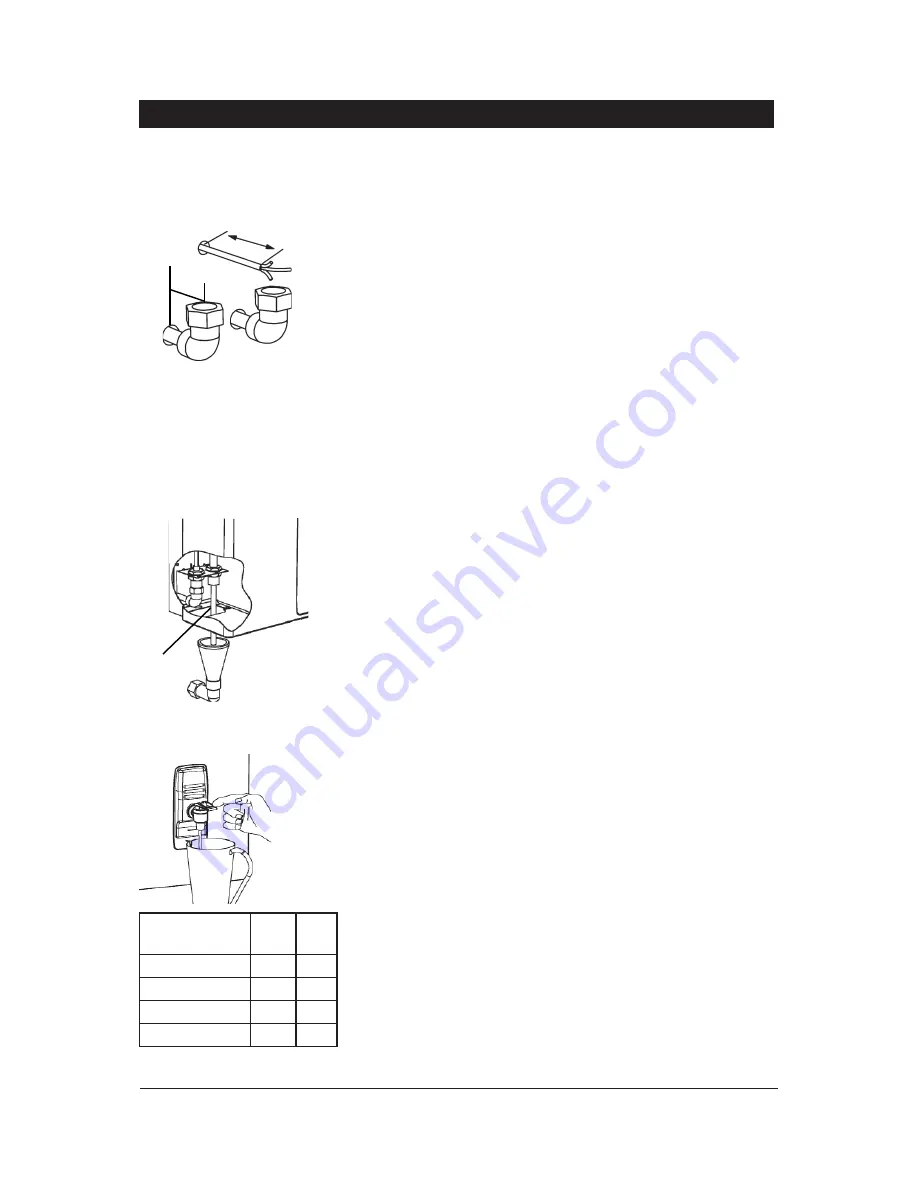

a) Plumbing

For exposed plumbing connection, connect the cold water inlet pipe from the base

of the heater directly to the 1/2” or 12.7 mm compression fittings.

For concealed plumbing connections, connect the cold water pipe through the rear

of the chassis using a 1/2” or 12.7 mm capillary elbow (# 63 Swivel Elbows).

Cold water pipes must be flushed before connection to the inlet. Any clogging

due to sediment or fines will adversely affect the operation of the heater.

It is recommended that the heater be installed with a stop cock which allows it

to be isolated from the mains supply for servicing.

Water pressure requirements:

Minimum - 1 bar (100 kPa) maximum - 7 bar (1000 kPa).

Warning:

If pressure is likely to exceed 7 bar, a pressure limiting valve must be

installed in the cold water supply line. Zenith recommends a valve rated at 3.5

bar (350 kPa) for this application.

b) Venting

A vent at the base of the heater must be plumbed to a safe visible location as,

under certain conditions, it may discharge cold or boiling water and/or steam.

For exposed vent plumbing, connect vent outlet from the base of heater to a 1/2”

or 12.7 mm pipe which has a continuous fall, is no more than 3 meters long, has

no more than 3 right angle bends, and discharges to a waste water drain.

For concealed vent plumbing, connect plumbing to the vent outlet from the

heater rear using a capillary elbow protruding 45 mm from the wall.

Alternatively attach a tun dish to the wall as shown and plumb away to waste.

d) Electrical

For concealed electrical connection, connect a power cable through the rear

access opening of the heater to the terminal block within the heater as shown.

For exposed electrical connection, connect a flex to a standard 13 amp double

pole fused spur power outlet on the wall within 1500 mm of the heater.

All isolation switches must have a contact separation of at least 3 mm in all poles.

Do not turn the power ON until the heater is filled with water.

Step 4 – Assembling

Place the heater case back on to the heater and secure the top 2 case screws.

Secure two bottom case screws.

Step 5 – Commissioning

Check previous steps. Turn water supply ON. Water is now flowing into heater,

check connections for leaks. Wait approximately 5 minutes and check outlet

tap for water. This is achieved by pulling the tap handle forward.

Power is only to be turned on when water is available from this outlet.

Turn power ON. After a short period, boiling water will be available and will be

maintained close to boiling point thereafter. Initial heating periods are shown in

the table on the left.

Installation Procedures

Continued

250mm

Wring

Concealed

Vent

Concealed

Inlet

45 mm

Visible Tundish

Vent line

Inlet water

temperature

15°C

10°C

1.5 Litre models

10 min 11 min

3.0 Litre models

16 min 17 min

5.0 Litre models

16 min 17 min

7.5 Litre models

23 min 24 min