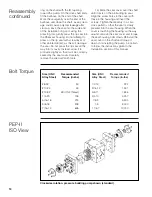

Size (UNC

Recommended

Alloy Steel)

Torque (in-lbs)

1/2-13

922

9/16-12

1,331

5/8-11

1,836

3/4-10

3,257

7/8-9

5,800

1-8

8,000

1 1/8-7

12,000

10

Reassembly

continued

Bolt Torque

Size (UNC

Recommended

Alloy Steel)

Torque (in-lbs)

#8-32

30

#10-24

43

#10-32

49 (UNF thread)

1/4-20

103

5/16-18

213

3/8-18

378

7/16-14

605

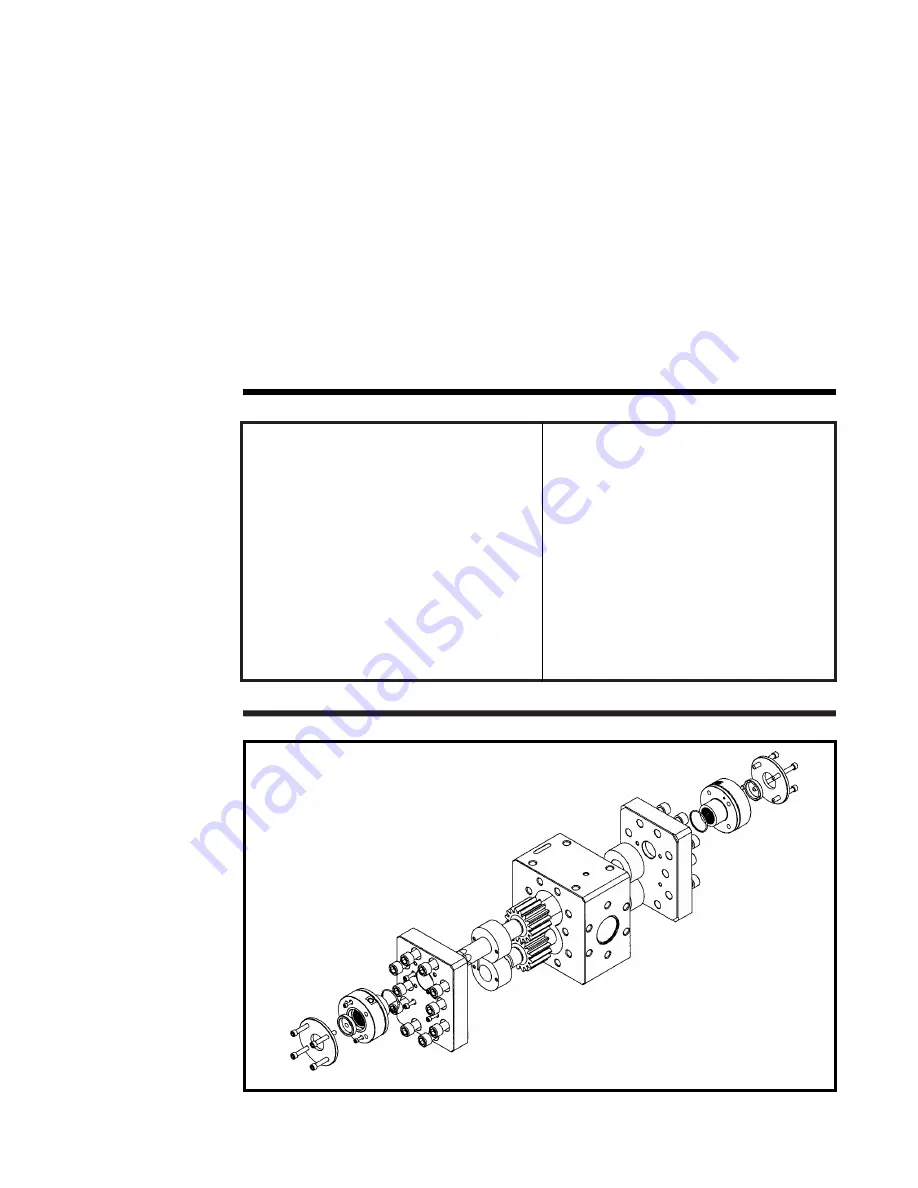

PEP-II

ISO View

Clockwise rotation, pressure building pump shown (standard).

ring on the shaft with the ID tapering

toward the pump. On the drive shaft ends,

fit the bullnose on the end of the shaft.

Work the seal gently over the end of the

bullnose and down the shaft, as any dam-

age could cause polymer leakage after

start-up. Ease the seal into the wide end

of the installation ring and, using the

pressing tool, gently press the lip seal into

the Rheoseal housing. Do not attempt to

press on the lip seal with screwdriver or

other pointed object, as this will damage

the seal. Do not press the lip seal all the

way into its cavity. Instead, allow it to

protrude slightly so that it will be correctly

seated by the seal cover. Carefully

remove the special Zenith tools.

14) Slide the seal cover over the shaft

until it rests on the protruding lip seal.

Align the screw holes in the cover with

those in the housing and insert the

screws. Tighten them evenly in a criss-

cross pattern so that the seal is slowly

pressed into the seal housing. When the

cover is touching the housing all the way

around, remove the seal cover and torque

the seal housing bolts down. Reinstall the

seal cover on the shaft and torque it

down. In reinstalling the pump, be certain

to follow the instructions given in the

Installation section of this manual.