Zenith

®

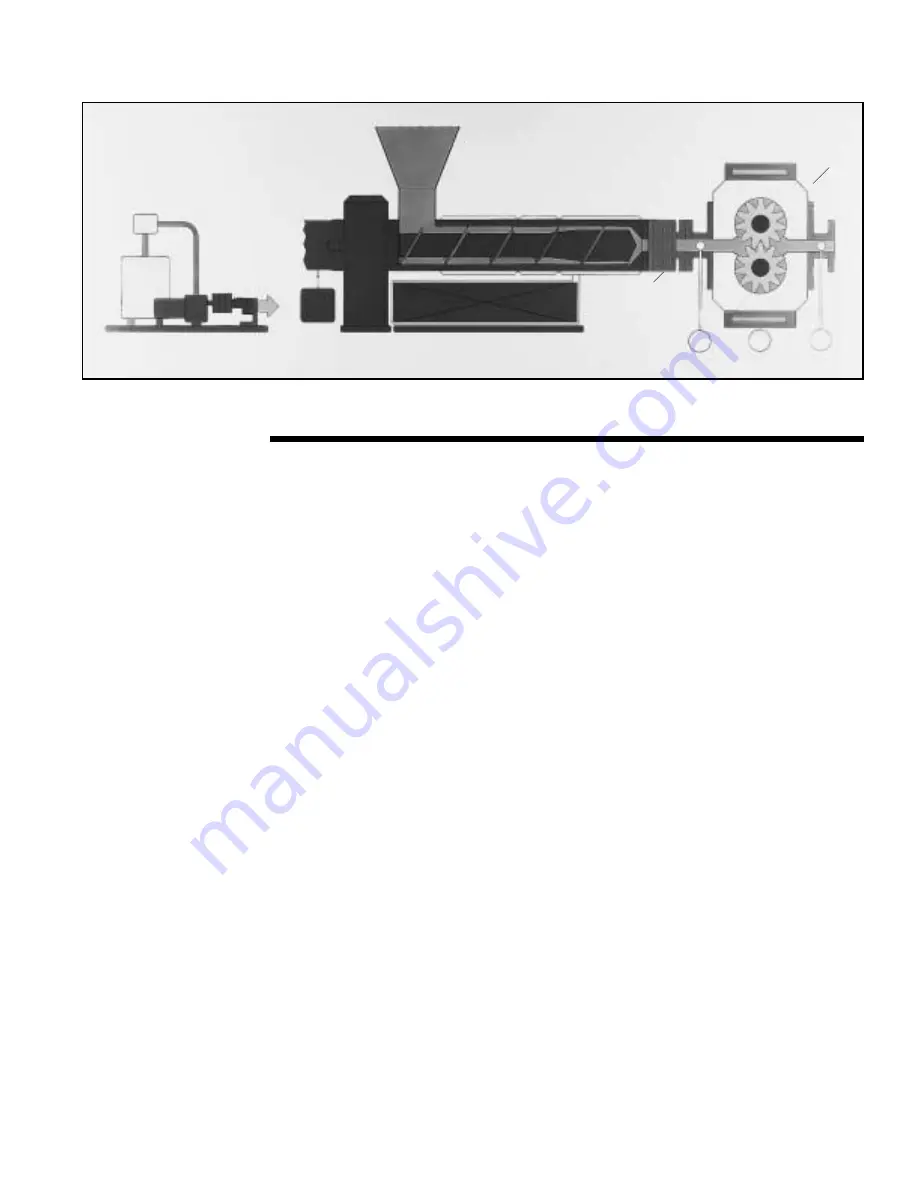

Pumps and The Extrusion Process

Design

Zenith Pumps can handle all your extrusion pumping applications including

additive injection for on-line compounding of tackifiers, colorants, stabilizers, etc.

3

ZENITH

ADDITIVE

INJECTION

SYSTEM

ELECTRIC

HEAT PLATE

PUMP

TEMPERATURE

INLET

PRESSURE

DISCHARGE

PRESSURE

ZENITH

PEP-II

PUMP

CHANGER

P

P

T

EXTRUDER

The PEP-II pump is constructed of two

gears rotating in mesh within a closely fit-

ted housing that is comprised of three

plates. The center, or gear plate, fits

closely around the outside diameter of the

metering gears and bearings. The front

and rear, or cover plates, sandwich the

center plate and restrict axial movement

of the gears and bearings. In capacities

of 5 cc/rev and larger, the driving gear is

manufactured integral with the drive shaft,

and the driven gear is machined integral

with its shaft. In capacities of 3.0 cc/rev

and below, the gears are keyed to their

respective shafts. In all capacities the

shafts are supported by “D” shaped

bearings which fit into the center plate. In

capacities of 40 cc/rev and above, these

bearings are located by two screws which

pass through the cover plates. In capacities

of 20 cc/rev and below, the bearings are

keyed to each other for accurate location.

Each cover plate is secured to the

center plate by 10 screws (6 screws for

below 5 cc/rev). Each side of the center

plate has a circular port in the center of a

bolt circle for the mounting of adapter

flanges that fit the pump to your equiment.

Threaded holes are provided on the top

and bottom of the center plate for the

mounting of heat plates and for the

mounting of the pump to its stand.

Thermocouple wells (1/8-27 NPT) are

located on the body of the pump.

A Zenith Rheoseal assembly secured

to each cover plate (front cover plate only

on 3.0 cc/rev and below) prevents leakage

around the shaft, using both dynamic and

static types of sealing mechanisms. A

Rheoseal consists of a helical groove on

the inner diameter, a cooling jacket and a

static, backup seal counter bore and

gland. These spiral grooves allow the

Rheoseal to act as a screw-type pump.

As the fluid attempts to leave the gear

pump, the shaft's rotary motion forces the

fluid into the grooves. This creates a pres-

sure greater than the pressure forcing

polymer out of the pump, thus returning

the polymer back towards the pump.

Since the rotary motion is required of the

shaft, two other static types of seals are

employed on the Rheoseal—a spring

energized lip-seal or a packing seal

secured by the gland. Also a flushing

cooling jacket surrounds a portion of the

grooved seal. Use of the cooling jacket

may be required for effective sealing if the

viscosity is below 1,000 poise at process

conditions. If used, water passing through

the housing cools the polymer, increasing

the effectiveness of the seal's pumping

action. A thermocouple well is provided

in the seal housing to allow for measuring

the temperature close to the region where

sealing actually occurs.

A complete line of accessories is

available and includes heating plates

(electric, oil and steam), adapter flanges,

mounting blocks and pump drive systems

complete with power package controls

and process controls. Please contact

Zenith or your local Zenith representative

for further information.