Operation

6

Installation

Polymer enters the PEP-II pump on the

suction side where shaft rotation exposes

gear tooth volumes between the gear

teeth. Polymer fills these spaces and is

transported to the discharge side where

the gear teeth mesh together, decreasing

the gear tooth volumes and displacing the

polymer. Due to the precision tolerances

and close clearances within the rotating

spaces, very high pressures can be

achieved at the pump discharge with

extremely high volumetric efficiencies.

As PEP-II pumps rely on the metered

polymer for lubrication of internal bearing

surfaces, the operating speed is designed

to be from 10 to 90 rpm on most extrusion

processes depending on process parame-

ters.

Do not allow the pump to run dry

or attempt to pump poor lubricating

fluids such as water or solvent.

When

high-viscosity fluids are used, more time

is required to fill the tooth volumes. As a

result, the inlet pressure must be

increased or the gears must rotate at a

slower speed to ensure complete volume

filling. Proper speed and inlet pressure

must always be maintained to prevent

cavitation and to ensure proper lubrication.

Slip can occur across the sides

of the gears from the high-pressure side

to the low-pressure side. The amount of

slip depends on four factors: polymer

viscosity, speed, differential pressure

and pump clearances. Under reasonably

stable operating conditions, slip is repeat-

able and predictable, and pump operation

can be adjusted to compensate.

Pumps should be carefully unpacked to

make sure that the shipment is complete.

If any items are missing or damaged, the

freight carrier and Zenith should be noti-

fied immediately.

To prepare the pump for use:

1) Where required, install the heat

plates as follows. Zenith-supplied heat

plates are machined to tolerances that

eliminate the need for heat transfer cement.

All bolts used should be lubricated with

high-temperature thread lubricant such

as DAG Dispersion 154, Felpro C-100 or

equivalent.

2) Place the top heat plate on the

pump, then place the insulation jacket on

top of the heat plate. Install and tighten

the bolts, taking care not to crack the

insulation block.

3) Repeat for the bottom plate, noting

that bottom heat plate mounting bolts are

typically used to mount the pump to its

mounting block.

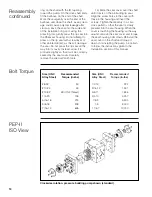

4) Place the supplied metal O-rings

into the counterbores in the pump ports,

and attach the inlet and discharge porting

flanges with lubricated screws. Replace

the O-rings after each use. Torque down

the screws in a crisscross pattern, taking

them first to 1/4 the recommended torque

value, then to 1/2, to 3/4 and finally to

their full recommended torque value as

shown on the table on page 10. If the

flanges are not supplied by Zenith, make

certain that their mating faces are flat,

with no pilots that protrude into the pump.

Check that the pump rotates freely by

turning the shaft with your hand.

5) The pump drive shaft should be

connected to the motor drive assembly

with a flexible coupling, a double universal

joint shaft or an appropriate Zenith SJMC

coupling. Side loading on the pump shaft

is to be avoided at all costs.

6) If water is used for sealing, connect

either 1/8-27 or 1/4-18 NPT fittings to the

Rheoseal and turn on the water. Be sure

to avoid excessive cooling, or damage to

the pump may occur.

7) Turn on the pump heaters. A 250° F

temperature rise per hour is recommended

for cold starts. No attempt should be

made to start the pump until the entire

pump is at operating temperature.

Cold

starts are the most common cause of

pump failure.

On start-up, a small amount of molten

polymer should be introduced into the

pump by slowly rotating (less than 5 rpm)

the pump by hand to ensure that the

pump is free turning and well lubricated.

With sufficient inlet pressure, the pump

can then be started at a very slow speed,

with discharge pressure low enough to

maintain low loading. When operating

satisfactorily, the pump and system may

now be gradually brought up to normal

process speeds and pressures.