- 4-13 -

DECK MECHANISM ADJUSTMENT

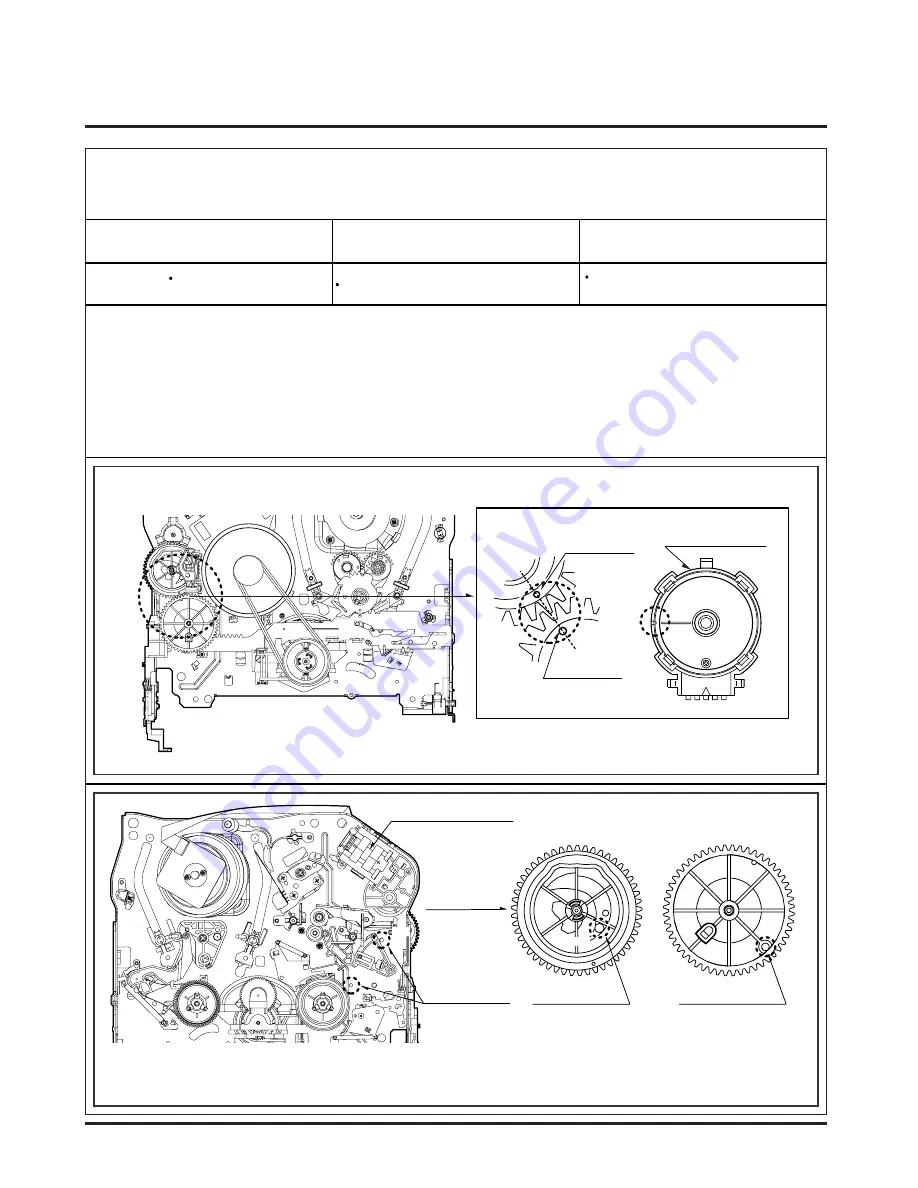

Purpose:To determine if the Mechanism is in the correct position, when a Tape is ejected.

1. Mechanism Alignment Position Check

1) Turn the Power S/W on and eject the Cassette by press-

ing the Eject Button.

2) Remove the Top Cover and Plate Assembly Top, visual-

ly check if the Gear Cam Hole is aligned with the

Chassis Hole as below Fig. C-2.

3) IF not, rotate the Shaft of the Loading Motor to either

clockwise or counterclockwise until the alignment is as

below Fig. C-2.

4) Remove the Screw which fixes the Deck Mechanism and

Main Frame and confirm if the Gear Cam is aligned with

the Gear Drive as below Fig. C-1(A).

5) Confirm if the Mode S/W on the Main P.C.Board is

aligned as below Fig. C-1(B).

6) Remount the Deck Mechanism on the Main P.C.Board

and check each operation.

Gear Cam

Gear Drive

(A)

Mode S/W

(B)

L/D Motor Assembly

Gear Cam

Chassis Hole

Gear Cam Hole

(A)

(B)

(A’)

(B’)

Gear Drive Hole

Test Equipment/ Fixture

Blank tape

Test Conditions (Mechanism

Condition)

Eject Mode (with Cassette ejected)

Check Point

Mechanism and Mode Switch Position

Fig. C-1

Fig. C-2

CHECK DIAGRAM

BOTTOM VIEW

TOP VIEW

Gear Cam (

o

) and Gear Drive (

o

) groove alignment

Summary of Contents for XBS341 Series

Page 1: ...SERVICE MANUAL MODELS XBS341...

Page 10: ...2 1 SECTION 2 AUDIO PART...

Page 12: ...3 2 VCR ELECTRICAL TROULBESHOOTING...

Page 13: ...3 3...

Page 27: ...SECTION 4 MECHANSIM OF VCR PART...

Page 39: ...4 12...

Page 41: ...4 14...

Page 51: ...4 24...

Page 58: ...5 1 DVD ELECTRICAL TROUBLESHOOTING 1 Test debug flow SECTION 5 DVD PART...

Page 59: ...5 2...

Page 60: ...5 3...

Page 61: ...5 4...

Page 62: ...5 5...

Page 63: ...5 6...

Page 67: ...5 10 2 Tray close waveform 3 Tray open waveform...

Page 69: ...5 12 6 LASER POWER CONTROL RELATED SIGNAL NO DISC CONDITION 7 DISC TYPE JUDGEMENT WAVEFORM...

Page 70: ...5 13...

Page 71: ...5 14 8 FOCUS ON WAVEFORM...

Page 72: ...5 15 9 SPINDLE CONTROL WAVEFORM NO DISC CONDITION...

Page 73: ...5 16 10 TRACKING CONTROL RELATED SIGNAL System checking...

Page 74: ...5 17 11 RF WAVEFORM 12 MT1379 AUDIO OPTICAL AND COAXIAL OUTPUT ASPDIF...

Page 75: ...5 18 13 MT1379 VIDEO OUTPUT WAVEFORM 1 Full colorbar signal CVBS 2 Y...

Page 76: ...5 19 3 C 14 AUDIO OUTPUT FORM AUDIO DAC 1 Audio related Signal...

Page 77: ...5 20 MEMO...

Page 80: ...2 2 2 3 BLOCK DIAGRAM...

Page 81: ...2 4 2 5 AUDIO SHEMATIC DIAGRAMS U COM SCHEMATIC DIAGRAM...

Page 82: ...2 6 2 7 FUNCTION POWER SCHEMATIC DIAGRAM...

Page 83: ...2 8 2 9 MAIN AMP SCHEMATIC DIAGRAM...

Page 84: ...2 10 2 11 WIRING DIAGRAM...

Page 86: ...2 14 2 15 PRINTED CIRCUIT DIAGRAM MAINAMP FRONT P C BOARD SOLDER SIDE...

Page 87: ...2 16 2 17 MAINAMP FRONT P C BOARD COMPONENT SIDE...

Page 88: ...2 18 2 19 FUNCTION POWER P C BOARD SOLDER SIDE...

Page 89: ...2 20 2 21 FUNCTION POWER P C BOARD COMPONENT SIDE...

Page 90: ...3 17 3 18 VCR SHEMATIC DIAGRAMS SYSTEM SCHEMATIC DIAGRAM...

Page 91: ...3 19 3 20 A AUDIO V VIDEO SCHEMATIC DIAGRAM...

Page 93: ...3 23 3 24 HIFI TUNER SCHEMATIC DIAGRAM...

Page 94: ...3 25 3 26 A V JACK SCART SCHEMATIC DIAGRAM...

Page 96: ...3 29 3 30 PRINTED CIRCUIT DIAGRAMS TUNER P C BOARD...

Page 97: ...3 31 3 32 VCR P C BOARD...

Page 98: ...3 33 3 34 VCR P C BOARD...

Page 99: ...5 22 5 21 DVD PART SCHEMATIC DIAGRAMS MPEG SCHEMATIC DIAGRAM...

Page 100: ...5 23 5 24 SERVO SCHEMATIC DIAGRAM...

Page 101: ...5 25 5 26 AUDIO SCHEMATIC DIAGRAM...

Page 102: ...5 27 5 28 INTERFACE SCHEMATIC DIAGRAM...

Page 103: ...5 29 5 30 VOLTAGE SHEET IC TR...

Page 104: ...5 31 5 32 PRINTED CIRCUIT DIAGRAM DVD P C BOARD SOLDER SIDE...

Page 105: ...5 33 5 34 DVD P C BOARD COMPONENT SIDE...

Page 107: ...MEMO MEMO...

Page 109: ...MEMO MEMO...

Page 115: ......