4-18

DECK MECHANISM ADJUSTMENT

Purpose: To correct for shift in the Roller Guide and X value after replacing the Drum.

8-2. Checking for tape curling or jamming

Test Equipment/ Fixture

• T-160 Tape

• T-120 Tape

Specification

• Be sure there is no tape jamming or curling at

the begining, middle or end of the tape.

VCR(VCP) State

• Run the CUE, REV, Play mode at the

beginning and the end of the tape.

Test Conditions (Mechanism Condition)

1) Confirm that the tape runs smoothly around the roller

guides, Drum and A/C Head Assemblies while abruptly

changing operating modes from Play to CUE or REV.

This is to be checked at the begining, middle and end

sections of the tape.

2) Confirm that the tape passes over the A/C Head

Assembly as indicated by proper audio reproduction and

proper tape counter performance.

Checking Procedure

7. Adjustment after Replacing Drum Assembly (Video Heads)

Test Equipment/ Fixture

• Oscilloscope

• Alignment Tapes

• Blank Tape

• Post Height Adjusting Driver

• Screw ) Type 5mm

Connection Point

• CH-1: PB RF Envelope

• CH-2: NTSC: SW 30Hz

PAL: SW 25Hz

• Head Switching Output

Test Point

• RF Envelope Output Test Point

Test Conditions

(Mechanism Condition)

• Play the Blank Tape

• Play an Alignment Tape

Adjustment Points

• Guide Roller Precise

Adjustment

• Switching Point

• Tracking Preset

• X-Value

Checking/Adjustment Procedure

Play a blank tape and check for tape curling or creasing around

the Roller Guide. If there is a problem then follow the procedure

4. "Guide Roller Height" and 5. "Audio Control(A/C) Head

Adjustment".

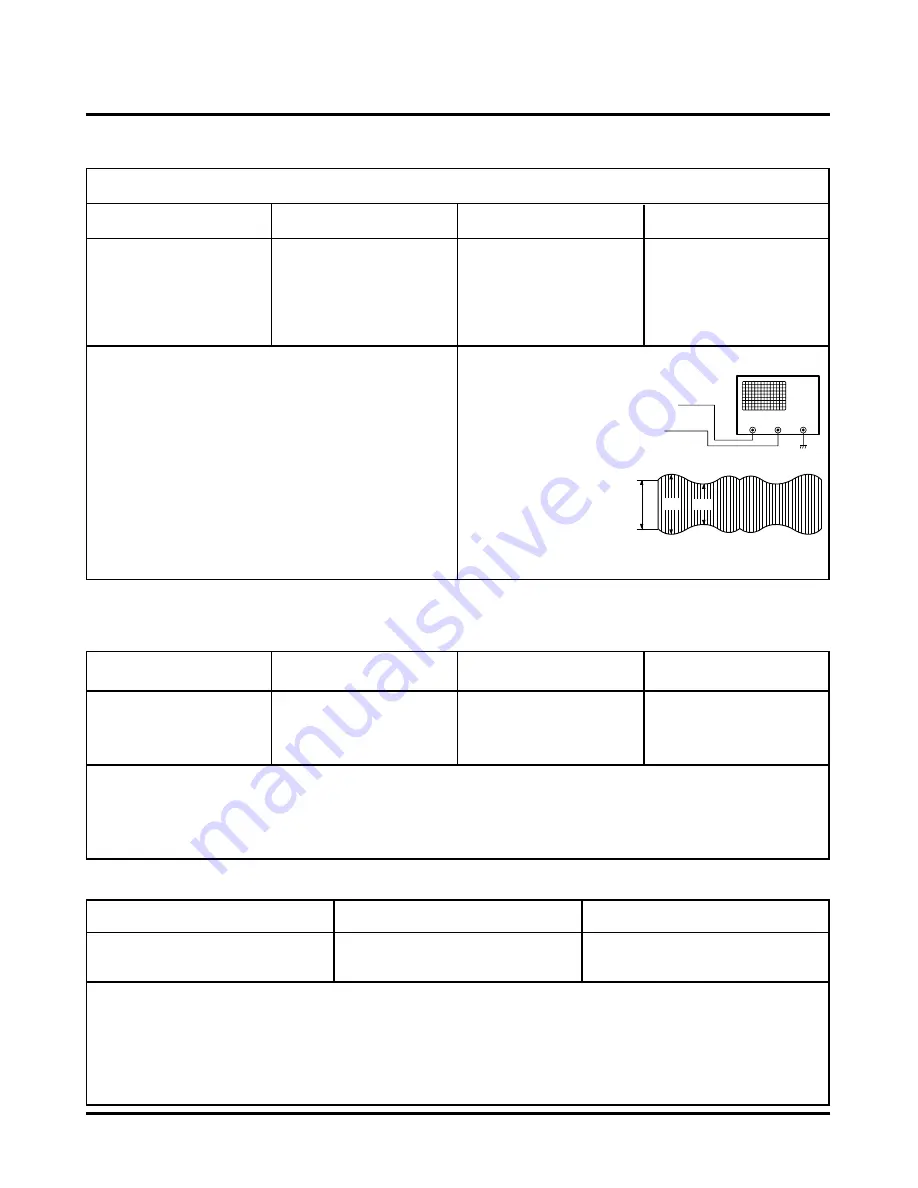

RF ENVELOPE OUTPUT TEST POINT

OSCILLOSCOPE

HEAD SWITCHING OUTPUT TEST

POINT

Connection Diagram

Waveform

V1/V MAX

E

E

0.7

V2/V MAX

E

E

0.8

RF ENVELOPE OUTPUT

Fig. C-7

8. Check the Tape Travel after Reassembling Deck Assembly.

8-1. Checking Audio and RF Locking Time during playback and after CUE or REV (FF/REW)

Test Equipment/ Fixture

• Oscilloscope

• Alignment Tapes(with 6H

3KHz Color Bar Signal)

• Stop Watch

Specification

• RF Locking Time: Less than 5

sec.

• Audio Locking Time:Less than

10sec

Test Equipment

Connection Points

• CH-1: PB RF Envelope

• CH-2: Audio Output

• RF Envelope Output Point

• Audio Output Jack

Test Conditions

(Mechanism Condition)

• Play an Alignment Tape

(with 6H 3kHz Color Bar

Signal)

Checking Procedure

Play an Alignment Tape then change the operating mode to

CUE or REV and confirm if the unit meets the above listed

specifications.

NOTES:

1) CUE is the forward search mode

2) REV is the backward search mode

3) Refer to the Play mede

V1

V

V2

CH1 CH2

Connection Points

Summary of Contents for XBS344 Series

Page 2: ......

Page 10: ...2 3 951 954 960 961 953 957 959 955 956 963 A90 2 Woofer Speaker Section DTE 5105WE...

Page 11: ...2 4 850 852 851A 851 853 854 857 858 A80 3 Speaker Section DTE 550TE...

Page 38: ...3 34 3 35 2 POWER SMPS CIRCUIT DIAGRAM 2 SR13601A R171 4 7K...

Page 39: ...3 36 3 37 3 JACK TUNER CIRCUIT DIAGRAM 03 08 15 SR13605A...

Page 43: ...3 44 3 45 7 KEY CIRCUIT DIAGRAM SR13610A...

Page 46: ...3 50 3 51 PRINTED CIRCUIT DIAGRAMS 1 MAIN P C BOARD LOCATION GUIDE...

Page 47: ...3 52 3 53 2 TUNER P C BOARD LOCATION GUIDE 3 POWER P C BOARD...

Page 48: ...3 54 3 55 4 KEY 1 LEFT P C BOARD LOCATION GUIDE 5 KEY 2 RIGHT P C BOARD LOCATION GUIDE...

Page 49: ......

Page 69: ...3 75 3 C IC507 PIN 26 FIG 12 3 2 Y IC507 PIN 21 FIG 12 2...

Page 77: ......

Page 79: ...CD DVD LD will not on SR13608A VZ DV51V SANYO 3 85 3 86 2 RF SERVO CIRCUIT DIAGRAM...

Page 80: ...VZ DV51V SANYO TUNER_L TUNER_R 3 87 3 88 3 AUDIO _COM CIRCUIT DIAGRAM DVD AMP...

Page 81: ...VZ DV51V SANYO FRONT_R FRONT_L REAR_R REAR_L 3 89 3 90 4 DIGITAL AMP CIRCUIT DIAGRAM DVD AMP...

Page 82: ...5 PWM CODEIC CIRCUIT DIAGRAM DVD AMP VZ DV51V SANYO 12 288MHz R R L L R L OPTICAL_IN 3 91 3 92...

Page 83: ...6 INTERFACE CIRCUIT DIAGRAM DVD AMP VZ DV51V SANYO 3 93 3 94...

Page 86: ...LOCATION GUIDE LOCATION GUIDE 3 99 3 100 PRINTED CIRCUIT DIAGRAMS 1 DVD AMP P C BOARD...

Page 87: ......

Page 119: ...MEMO...

Page 125: ......

Page 127: ......

Page 159: ......