MAINTENANCE/INSPECTION PROCEDURE

4-20

2. Required Maintenance

The recording density of a VCR(VCP) is much higher than

that of an audio tape recorder. VCR(VCP) components must

be very precise, at tolerances of 1/1000mm, to ensure com-

patibility with the other VCRs. If any of these components are

worn or dirty, the symptoms will be the same as if the part is

defective. To ensure a good picture, periodic inspection and

maintenance, including replacement of worn out parts and

lubrication, is necessary.

3. Scheduled Maintenance

Schedules for maintenance and inspection are not fixed

because they vary greatly according to the way in which the

customer uses the VCR(VCP), and the environment in which

the VCR(VCP) is used.

But, in general home use, a good picture will be maintained

if inspection and maintenance is made every 1,000 hours.

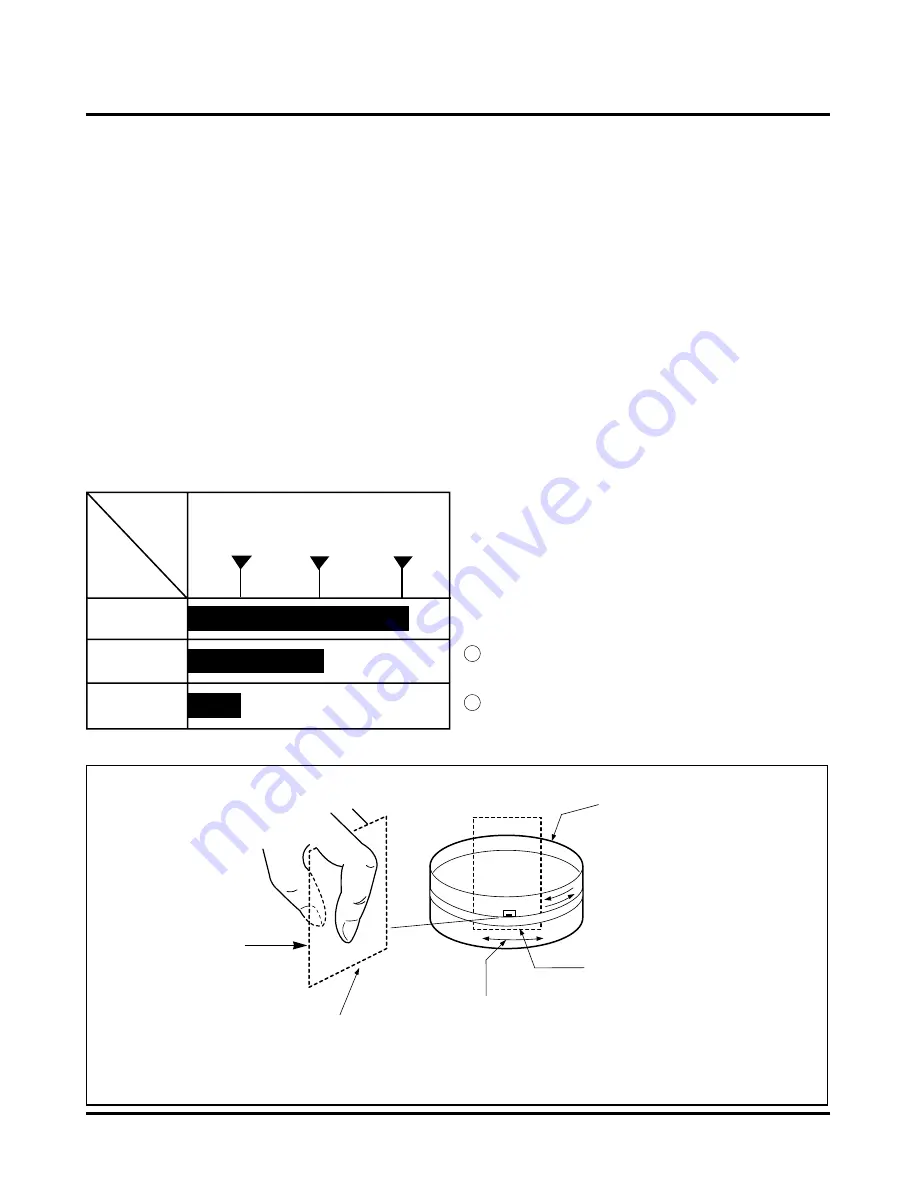

The table below shows the relation between time used and

inspection period.

Table 1

4. Supplies Required for Inspection and

Maintence

(1) Grease : Kanto G-311G (Blue) or equivalent

(2) Isopropyl Alcohol or equivalent

(3) Cleaning Patches

(4) Grease : Kanto G-381(Yellow)

5. Maintenance Procedure

5-1) Cleaning

(1) Cleaning video head

First use a cleaning tape. If the dirt on the head is too

stubborn to remove by tape, use the cleaning patch. Coat

the cleaning patch with Isopropyl Alcohol. Touch the

cleaning patch to the head tip and gently turn the

head(rotating cylinder) right and left.

(Do not move the cleaning patch vertically. Make sure

that only the buckskin on the cleaning patch comes into

contact with the head. Otherwise, the head may be dam-

aged.)

Thoroughly dry the head. Then run the test tape. If lso-

propyl Alcohol remains on the video head, the tape may

be damaged when it comes into contact with the head

surface.

(2) Clean the tape transport system and drive system, etc, by

wiping with a cleaning patch wetted with Isopropyl

Alcohol.

NOTES:

1

It is the tape transport system which comes into contact

with the running tape. The drive system consists of those

parts which moves the tape.

2

Make sure that during cleaning you do not touch the tape

transport system with excessive force that would cause

deformation or damage to the system.

About 1

year

One hour

Two hours

Three hours

When

inspection is

necessary

Average

hours used

per day

About 18

months

About 3

years

Fig. C-9-4

Drum

(Rotating Cylinder)

Head Tip

Coat With Isopropyl Alcohol

Touch this section of cleaning

patch to the head tip and gently

turn the Drum (Rotating Cylinder)

Cleaning Patch

Summary of Contents for XBS344 Series

Page 2: ......

Page 10: ...2 3 951 954 960 961 953 957 959 955 956 963 A90 2 Woofer Speaker Section DTE 5105WE...

Page 11: ...2 4 850 852 851A 851 853 854 857 858 A80 3 Speaker Section DTE 550TE...

Page 38: ...3 34 3 35 2 POWER SMPS CIRCUIT DIAGRAM 2 SR13601A R171 4 7K...

Page 39: ...3 36 3 37 3 JACK TUNER CIRCUIT DIAGRAM 03 08 15 SR13605A...

Page 43: ...3 44 3 45 7 KEY CIRCUIT DIAGRAM SR13610A...

Page 46: ...3 50 3 51 PRINTED CIRCUIT DIAGRAMS 1 MAIN P C BOARD LOCATION GUIDE...

Page 47: ...3 52 3 53 2 TUNER P C BOARD LOCATION GUIDE 3 POWER P C BOARD...

Page 48: ...3 54 3 55 4 KEY 1 LEFT P C BOARD LOCATION GUIDE 5 KEY 2 RIGHT P C BOARD LOCATION GUIDE...

Page 49: ......

Page 69: ...3 75 3 C IC507 PIN 26 FIG 12 3 2 Y IC507 PIN 21 FIG 12 2...

Page 77: ......

Page 79: ...CD DVD LD will not on SR13608A VZ DV51V SANYO 3 85 3 86 2 RF SERVO CIRCUIT DIAGRAM...

Page 80: ...VZ DV51V SANYO TUNER_L TUNER_R 3 87 3 88 3 AUDIO _COM CIRCUIT DIAGRAM DVD AMP...

Page 81: ...VZ DV51V SANYO FRONT_R FRONT_L REAR_R REAR_L 3 89 3 90 4 DIGITAL AMP CIRCUIT DIAGRAM DVD AMP...

Page 82: ...5 PWM CODEIC CIRCUIT DIAGRAM DVD AMP VZ DV51V SANYO 12 288MHz R R L L R L OPTICAL_IN 3 91 3 92...

Page 83: ...6 INTERFACE CIRCUIT DIAGRAM DVD AMP VZ DV51V SANYO 3 93 3 94...

Page 86: ...LOCATION GUIDE LOCATION GUIDE 3 99 3 100 PRINTED CIRCUIT DIAGRAMS 1 DVD AMP P C BOARD...

Page 87: ......

Page 119: ...MEMO...

Page 125: ......

Page 127: ......

Page 159: ......