22

10. Storage

• Aged fuel is one of major causes of engine

starting failure. Before storing the unit, empty the

fuel tank and run the engine until it uses all the

fuel left in the fuel line and the carburetor. Store

the unit indoor taking necessary measures for

rust prevention.

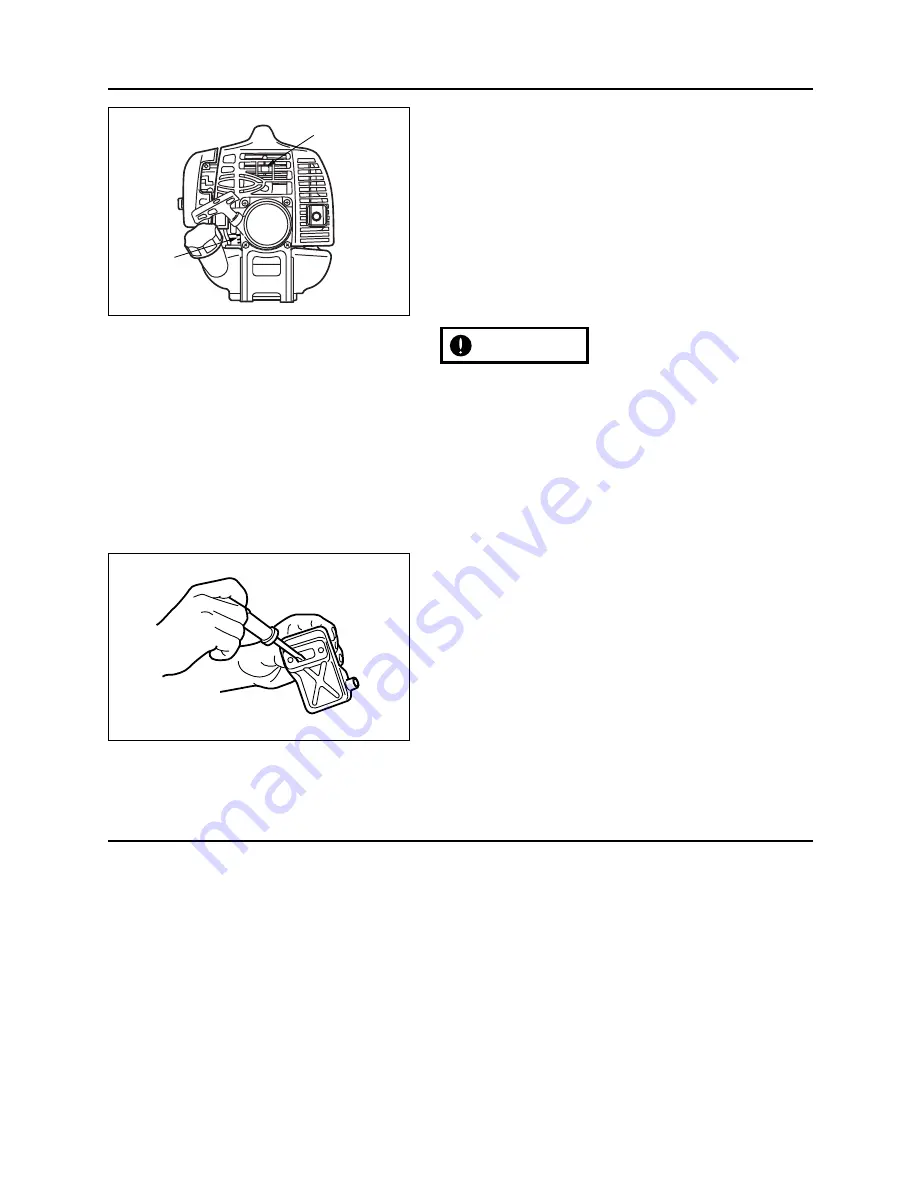

9. Maintenance

sure that the muffler is clean and free of

wood chips, leaves, and other waste before

use.

• Check the intake air cooling vent and the area

around the cylinder cooling fins after every 25

hours of use for blockage, and remove any

waste which has attached itself to the

brushcutter. Note that it is necessary to remove

the engine cover shown in (MA7) in order to be

able to view the upper part of the cylinder.

• If waste gets stuck and causes blockage around

the intake air cooling vent or between the

cylinder fins, it may cause the engine to

overheat, and that in turn may cause mechanical

failure on the part of the brushcutter. (MA7)

(1) cylinder

(2) intake air cooling vent (back)

■

PROCEDURES TO BE PERFORMED AFTER

EVERY 100 HOURS OF USE

1. Remove the muffler, insert a screwdriver into the

vent, and wipe away any carbon buildup. Wipe

away any carbon buildup on the muffler exhaust

vent and cylinder exhaust port at the same time.

2. Tighten all screws, bolts, and fittings.

3. Check to see if any oil or grease has worked its

way in between the clutch lining and drum, and if

it has wipe it away using oil-free, lead-free

gasoline.

IMPORTANT

MA8

(1)

(2)

MA7