GB-17

BK3420FL-EZ

G

B

9. Maintenance

WARNING

• Be sure to stop the engine when carrying out inspection and maintenance.

• Do not modify the machine or disassemble the engine.

• Use ZENOAH’s genuine parts or designated parts when replacing parts.

• If you cannot inspect or maintain the machine yourself, contact the shop where you bought it.

1 Blade

2 Debris guard

3 Grip

4 Throttle lever

5 Throttle wire

6 Fuel tank

7 Shoulder belt

8 Flexible shaft

9 Gear case

10 Parts to be tightened

•

The mounting bolt has become loose.

•

Tighten

• Broken, cracked, chipped, or bent.

• Replace

•

The blade edges have worn out.

• Re-sharpen or replace

• Mounted has become loose.

•

Tighten

• Broken.

• Replace

• Oil has stuck to the grip.

• Wipe of

f

• Does not move smoothly

.

• Repair or replace

• The play is too large or too small.

• Repair

• The throttle wire does not move smoothly

.

• Repair or replace

• Fuel leaks out.

• Repair or replace

•

The fuel pipe has been damaged.

• Replace

• Broken or cracked.

• Repair or replace

•

The connecting part has become loose.

• Repair or replace

• Cut off, cracked, discolored, or deformed.

• Replace

•

The shaft has become loose.

• Repair or replace

• Loose or slipped of

f.

•

Tighten or repair

�

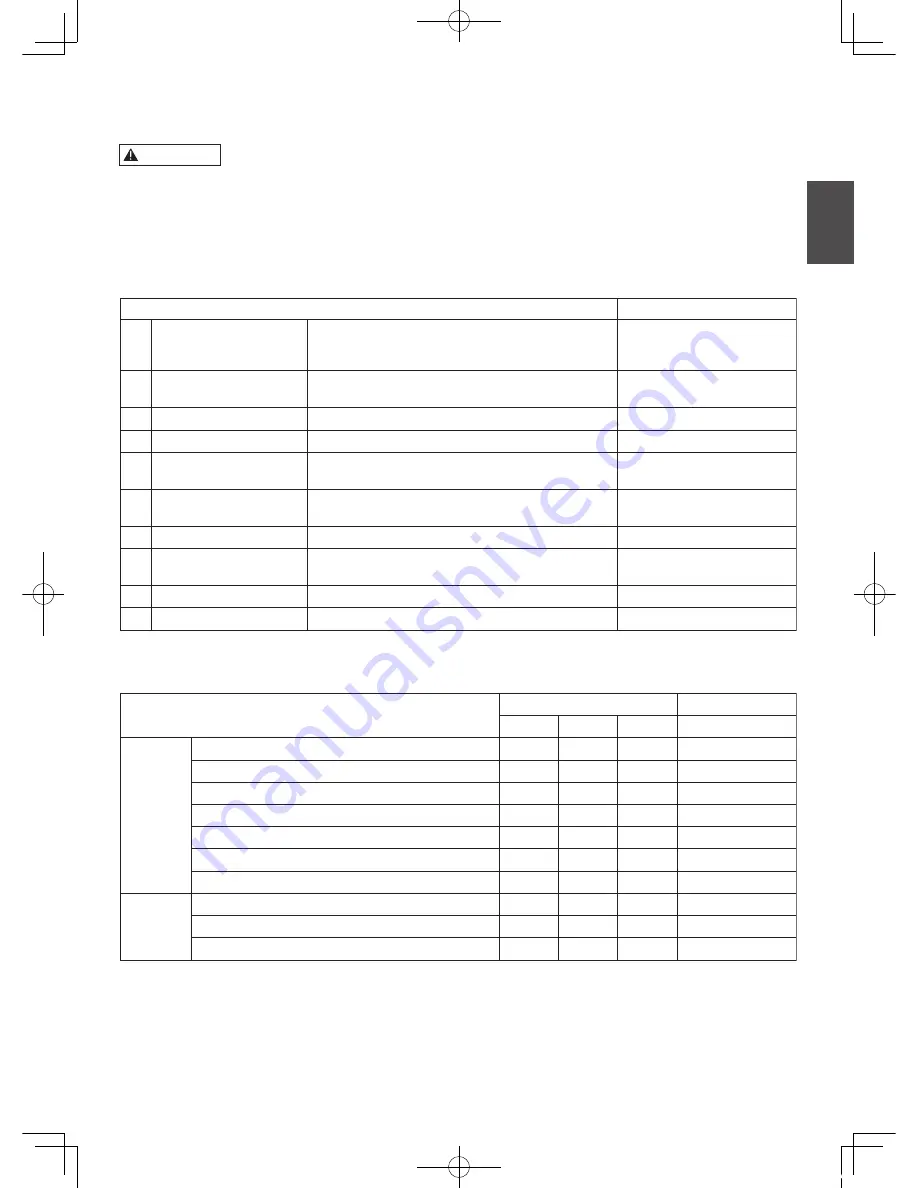

INSPECTION BEFORE AND AFTER CUTTING

Inspect the following items before and after cutting.

INSPECTION ITEMS

MEASURES

25 hours 50 hours 100 hours

Removal of dust from cylinder fin

O

O

O

Cleaning of the air cleaner element

O

O

O

Checking, cleaning and adjustment of the spark plug

O

O

O

Gap 0.6 to 0.7 mm

Engine

Cleaning of the fuel tank

O

O

Additional tightening of the bolt for mounting the cylinder

O

Additional tightening of the parts for the engine

O

Removal of the carbon from the muffler

O

Supply of grease for the gear case

O

O

O

Main body Removal of the contamination of the clutch drum

O

Supply of grease for the flexible shaft

O

O

O

�

REGULAR INSPECTION

Carry out inspection for each period of use as specified below.

INSPECTION AND MAINTENANCE ITEM

PERIOD OF USE

REMARKS

01-BK3420FL-EZ_GB_207_三.indd 17

12.9.21 1:24:16 PM