GB-20

BK3420FL-EZ

9. Maintenance

■

GEAR CASE

Supply lubricating grease to the gear case every 25

hours of use.

Designated grease

Lithium-based heat-resistant grease (#2)

[How to supply grease]

1. Remove plugs both sides of gear case, and pour

grease from the one side plug hole.

2. Stop supplying the grease when all the old grease

has been pushed out from the opposite plug hole,

and mount the plug in its original position.

3. Wipe off the pushed-out grease, and mount the blade

and the blade rest plate in their original positions.

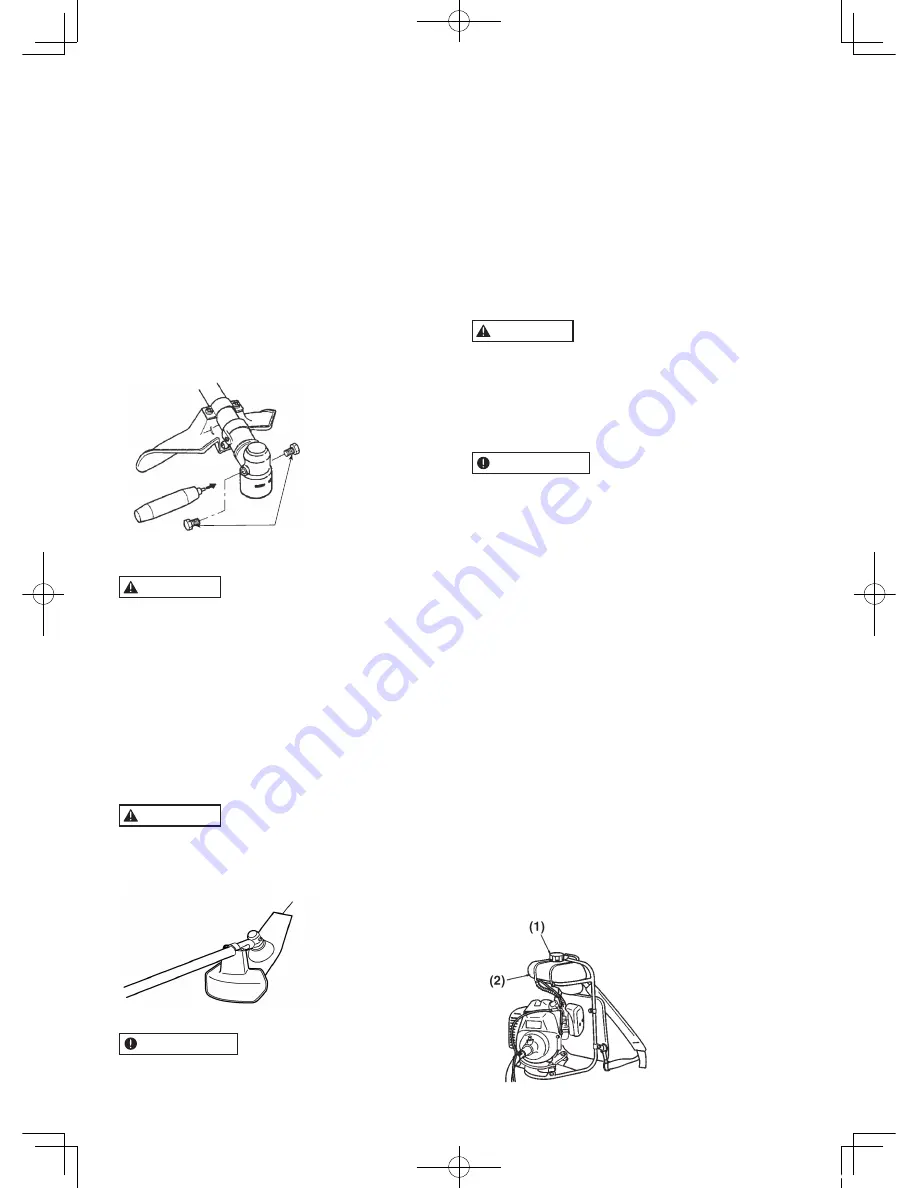

(1)

(1) Plug

■

BLADE

WARNING

• In order to carry out cutting work safely, be sure

to check the blade before you begin and after you

finish your work. If you continue to use a blade

which has become loosened, chipped, cracked,

broken, or bent, such a blade might disintegrate

and broken pieces might hit you or adjacent work-

ers, causing a serious injury.

• Be sure to stop the engine before checking the

blade. If you check the blade with the engine still

in operation, the blade might begin to rotate be-

cause of overturning of the machine, etc.

WARNING

• When checking the blade, be sure to stop the

engine and wear gloves. Handling the blade with

bare hands might cause an injury.

(1) Blade

(1)

IMPORTANT

Do not use a blade which has worn away and has be-

come round. Such a blade does not cut well, and grass

and twigs easily wind themselves around it, thus increas-

ing the load on your arm during cutting and affecting the

fuel consumption and life-span of the machine.

Be sure to check the blade before or after using the

machine. If anything is wrong with the blade, replace it

with a new one, or sharpen it again.

■

MAINTENANCE BEFORE LONG-TERM STOR-

AGE

WARNING

This machine is highly inflammable.

• When you take fuel out, keep the fuel tank well

away from flames.

• Be careful not to spill the fuel, and completely wipe

off all fuel spills.

IMPORTANT

• If you will not use the machine for a long time (two

months or more), take out the fuel from the fuel tank

and carburetor. If you leave the fuel tank and carbu-

retor filled with fuel for a long time, the fuel might

deteriorate and clog the inside of the carburetor, thus

causing engine problems (such as wrong start or

insufficient output).

• When storing the machine for a long time, loosen the

cap of the fuel tank slightly. Excessive tightening of

the cap might deform its packing over time.

1. Brush off dirt from the machine, and check the dam-

age or slack of each part. If you find any abnormal

part, repair it completely ready for the next time the

machine is used.

2. Extract fuel from the fuel tank, switch on the engine,

and leave it running until it stops naturally.

3. Remove the spark plug, and pour 1 to 2 ml of 2-cycle

oil into the engine. Draw the starter rope two to three

times, set the plug back, and stop it at the contrac-

tion position.

4. Supply some grease to the gear case, and apply

anti-rust oil to the metal parts such as the throttle

wire.

5. Apply a little oil to the blade, put the cover on the

blade, and keep the machine in a safe place away

from heat and humidity.

(1) Tank cap

(2) Fuel tank

01-BK3420FL-EZ_GB_207_三.indd 20

12.9.21 1:24:18 PM