9. Maintenance

(EX-LRT only)

■

BLADES (MA1)

• When refilling the tank or resting, it is often a

good idea to use the time to oil the cutting

blades.

• If a gap exists between the upper and lower

blades, follow the procedure below to adjust

them so that they fit more closely together.

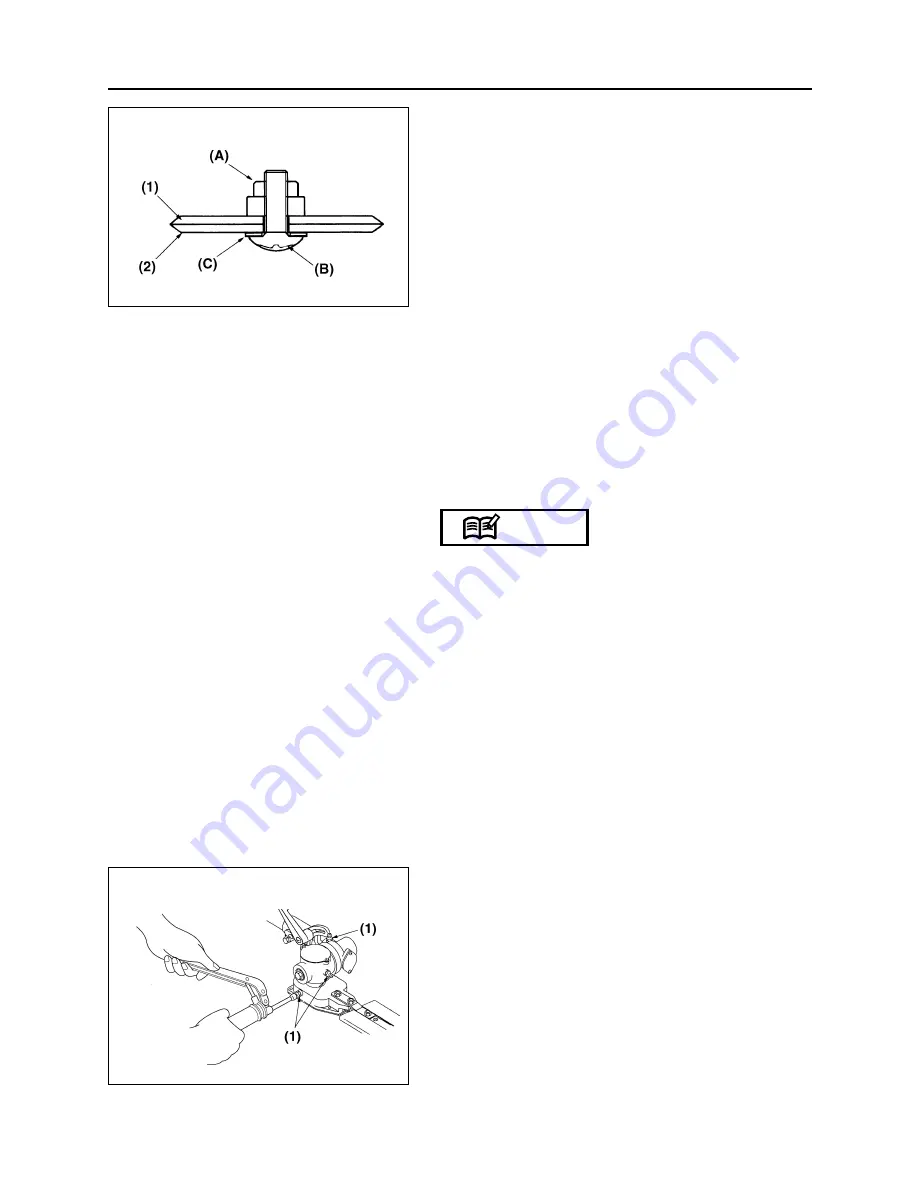

1. Loosen lock nut (A) as shown in the diagram.

2. Tighten screw (B) fully, and then turn one-

third to one-half of a rotation backward.

3. While holding onto the screw to keep it in

position, tighten the lock nut.

4. Check to make sure that the flat washer (C) is

loose enough so that it may be turned by

pressing on it with a finger.

(1) Upper blade

(2) Lower blade

Screwing in the screw too tightly may make it

impossible for the blades to move. Conversely, not

screwing in the screw tightly enough may make the

blades of the trimmer feel dull and cause leaves

and branches to become caught in the blades of

the trimmer.

QUICK TIP

If the blades become so worn down that it is no

longer possible to eliminate the gap between them,

you should contact the authorized RedMax

servicing dealer from which you purchased your

RedMax® trimmer to have the blades resharpened

or replaced.

■

GEAR CASE

The reduction gears are lubricated by

multipurpose, lithium-based grease in the

gearcase.

Supply new grease every 25 hours of use or more

often depending on the job condition.

When adding lubricant, use a grease gun to insert

lubricant into the three grease nipples located on

the gear case. (MA2)

(1) Grease fitting

NOTE

EX-LRT

MA1

EX-LRT

MA2

39

Summary of Contents for EX-BC

Page 46: ...12 Parts list 46 Fig 1 EXZ PU S N 302845 and up...

Page 48: ...12 Parts list 48 Fig 2 EX BC S N 302960 and up...

Page 50: ...Fig 3 ENGINE UNIT 50100000 and up 50 12 Parts list...

Page 52: ...12 Parts list 52 Fig 4 EX LRT S N 000531 and up...

Page 54: ...12 Parts list 54 Fig 5 EX PS S N 000000 and up...

Page 56: ...12 Parts list 56 Fig 6 EX HE S N 000101 and up...