NS3526

GB-10

NOTE

• When restarting immediately after stopping the en-

gine, set the choke lever to "open" and the throttle

lever to "slow".

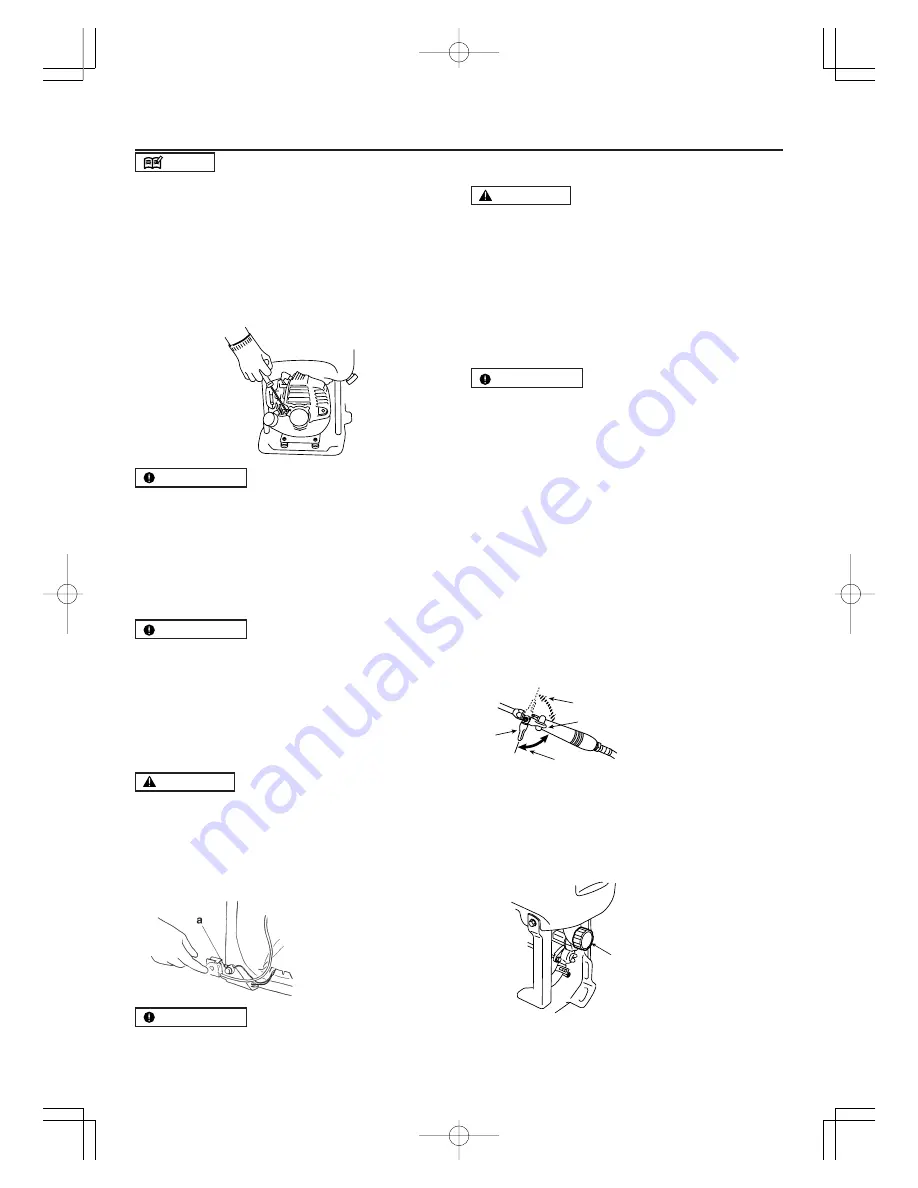

3. Place the sprayer in a stable location, and pull the

starter knob with the right hand while holding the

chemical tank down with the left hand. The starter knob

should first be pulled out lightly, then, when resistance

is felt, pulled more swiftly and vigorously.

IMPORTANT

• Do not pull the rope out completely or release the knob

so that the rope returns, as this can cause starter mal-

function.

4. Once the engine has started, gradually open the

choke, warm up at low speed for 1-2 minutes, then

return the throttle lever to the "slow" position.

IMPORTANT

• If the rope is pulled continuously with the choke

closed, the spark plugs may become flooded and the

engine may fail to start. If so, you should first remove

the spark plugs and dry the electrodes, then repeat

the starting procedure.

■

Stopping engine

WARNING

• Stop the engine immediately in the event of an emergency.

1. Lower the throttle lever fully and cool the engine down

for 1-2 minutes at low speed.

2. Hold down stop switch on the left side of the sprayer

frame until the engine has come to a complete stop .

IMPORTANT

• Except for an emergency, avoid stopping the engine

while pulling the throttle trigger.

■

Spraying

WARNING

• Please use correctly, observing the precautions in this

Manual ("For Safe Operation", p5 to 7).

• Before lifting the sprayer onto your back, check that

the chemical tank and fuel tank caps are tightly closed.

• When spraying, do not point the nozzle at your face,

or at other people, animals, etc.

• If the sprayer is tilted too much, chemical fluid or fuel

may leak out through the air holes in the cap. When

using, always try to maintain an upright posture.

IMPORTANT

• If the chemical tank becomes empty while spraying,

reduce the engine to low speed immediately. Empty

running of the engine may cause the spray pump to

break.

• Please avoid using multiple nozzles, jet nozzles, or

other nozzles that give a large spray volume, as spray-

ing efficiency is sometimes impaired owing to insuffi-

cient pressure.

■

Spraying procedure

1. Start the engine, and lift the sprayer onto your back.

2. Adjust the carrying band to a suitable length for car-

rying.

3. Increase the engine speed, and open the spray cock.

Chemical fluid starts to spray out from the nozzle in

the form of mist.

4. When stopping work, close the spray cock fully and

reduce the engine speed.

c

a

b

b

■

Cleaning after completion of spraying

1. Loosen the fluid drain cap , transfer the chemical fluid

left inside the tank into a suitable container, and pro-

cess appropriately with all due consideration to safety.

2. Pour about 5 litres of clean water into the chemical

tank, spray through the nozzle for 2-3 minutes, and

drain the water left inside the tank.

a

a. Stop switch

a. Spray cock

b. Close

c. Open

a. Fluid drain cap

9. Operation

When disposing your machine, fuel or oil for the machine,

be sure to allow your local regulations.

■

Disposal