9

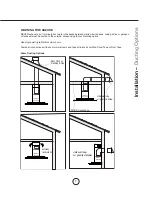

1. Measure from range top to hood bottom and mark line A.

(28” minimum from range top) .

2. Plum and mark center line.

3. Mark mounting height line B. (16” from line A)

4. Mark mounting spread from C/L. (8-7/8”)

5. Fasten (2) M4 x 1-1/2” screws into studs on line B but

do not tighten all the way.

Note: Wood blocking may

need to be added behind the drywall if no studs are

present. Wall anchors may also be used but check

local codes before using wall anchors.

6. Remove the (2) metal mesh fi lters.

7. Remove the (2) charcoal fi lter brackets located inside

the hoood behind the metal mesh fi lters. Each bracket is

secured with (4) 3/16 x 6 Philips head screws.

Note: If

you are not recirculating the hood you may discard

the charcoal brackets.

8. Hang hood onto the mounting screws and hand tighten

each screw. (fi g A) Secure third M4 x 1-1/2” screw

through inside of hood into wall for extra support. (fi g A2)

9. Center and attach duct cover mounting bracket to wall

just below the ceiling or soffi t using (2) M4 x 1” screws.

10. Install electrical and duct work. Seal duct work with

aluminum duct tape.

11. Power up hood and check for leaks around duct tape.

12. Place telescopic duct covers onto hood and extend

inner (top) duct cover upwards and secure to duct cover

bracket using (2) M3.5 x 8 screws. Secure bottom duct

cover to hood body by also using (2) M3.5 x 8 screws.

* If using hood in recirculating mode you must secure the air

diverter plate onto wall before installing duct work and

duct covers. Turn to page 10 for more details.

16”

28” min

Brackets are

pre-installed

CAUTION: At least two installers are

required due to the weight and size of the

hood.

!

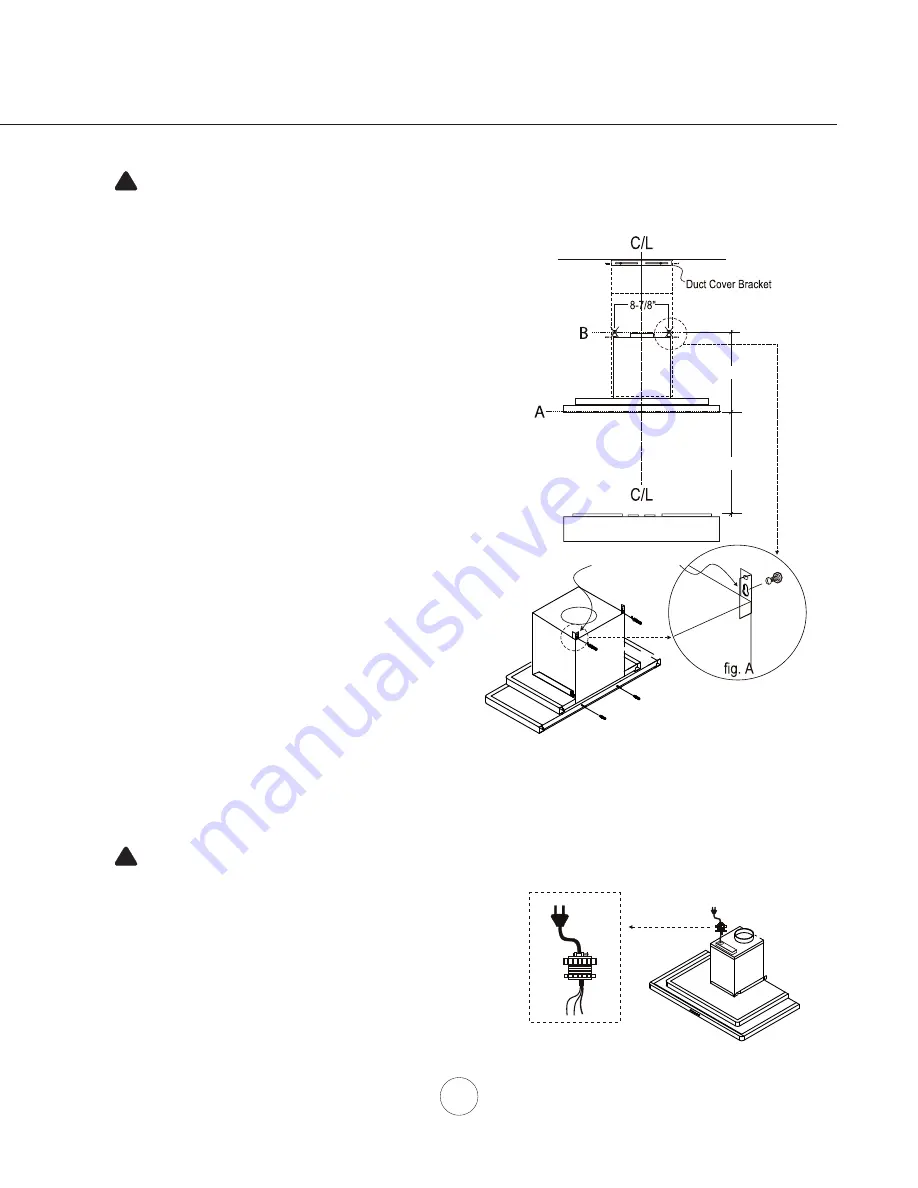

WARNING: Electrical wiring must be done by a qualified person(s) in

accordance with all applicable codes and standards. This range hood must be

properly grounded. Turn off electrical power at service entrance before wiring.

!

Installation –

Mounting the Hood

Cable Lock

Cable Lock

A cable locking connector (not supplied) might

be required by local codes. Check with local

requirements and codes, purchase and install

appropriate connector if necessary.

Summary of Contents for Firenze ZFI-M90S

Page 2: ...www zephyronline com...