7

10.

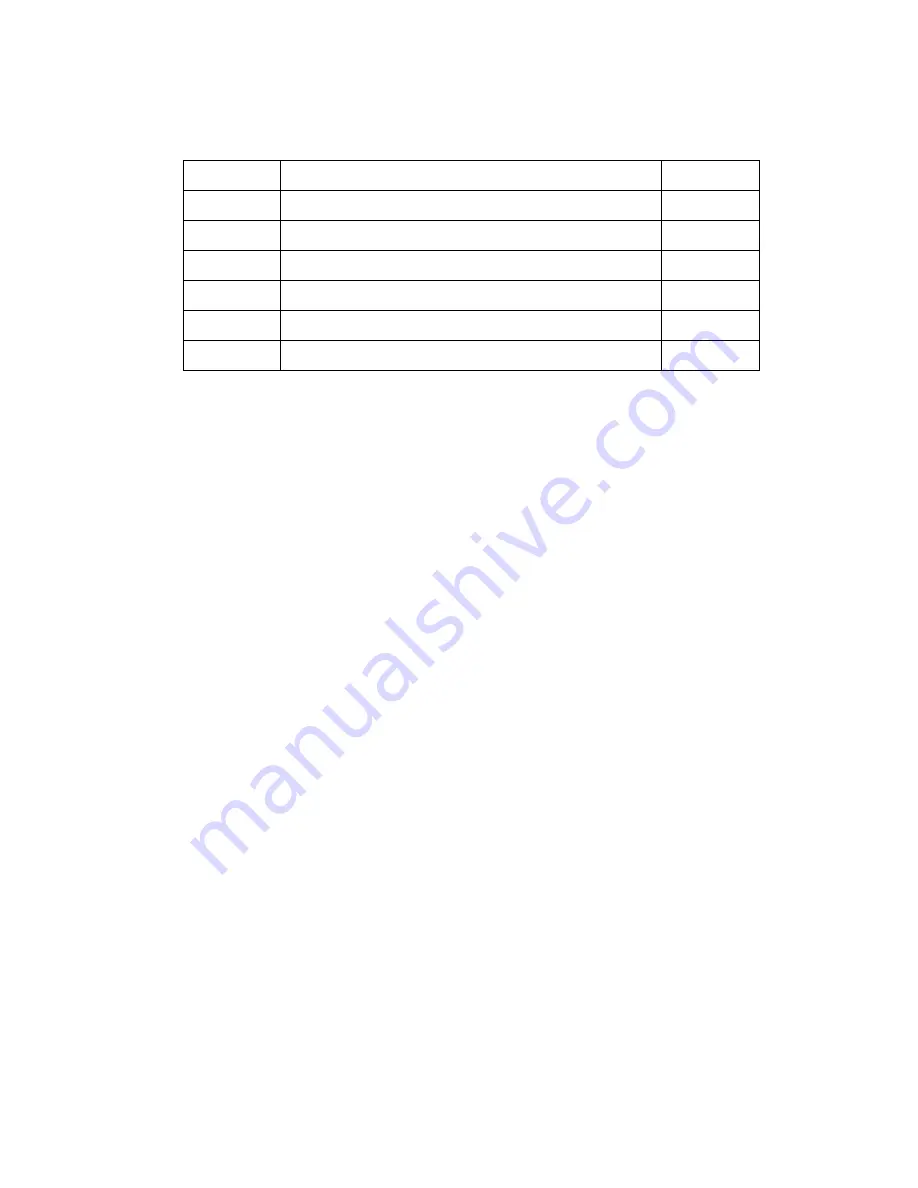

List of Contents

NO

Description

Qty

1

Air Compressor

1

2

Air Filter

2

3

Oil Breather Plug

1

4

Rubber Dampers

2

5

Operation Manual

1

6

Wheel Kit

1

11.

Warranty Information

SWP’s Zephyr range of air compressors are covered by a 12-months warranty

period providing the unit has been serviced maintained and installed in accordance

with SWP guidelines.

All compressors must be installed in a large, well ventilated, dust free area and

sheltered away from either rain or frost. The unit should be positioned with at

least one metre of free space all around the unit to aid both ease of service and

cooling airflow.

All single phased compressors fitted with a 13amp plug are designed to plug

directly in to a standard 13amp socket.

Exclusion to warranty cover are detailed below:

A

The cost of routine replacement parts and consumable items,

e.g. Air filters, belts, lubricants shall not be covered by the

warranty.

B

Any breakdown or failure caused by interference of any kind

with the product or its mechanisms or by modifications or

repairs carried out by an unauthorized person or business.

C

Damaged to the product or its component parts caused by

incorrect use, abuse, negligent, lack of proper maintenance or

by external cause. E.g. incoming power supply or local

environment.

D

Minor adjustments of any part or components on the machine which do

not necessitate the repair or replacement of part.

Summary of Contents for ZC350

Page 7: ...5 9 Parts Diagram...