ZDK 250 135/155

Installation

29

www.zepro.com

2x M12x100 8.8

80 Nm

2x M12x80 8.8

80 Nm

2x M12x80 8.8

80 Nm

2x M12x100 8.8

80 Nm

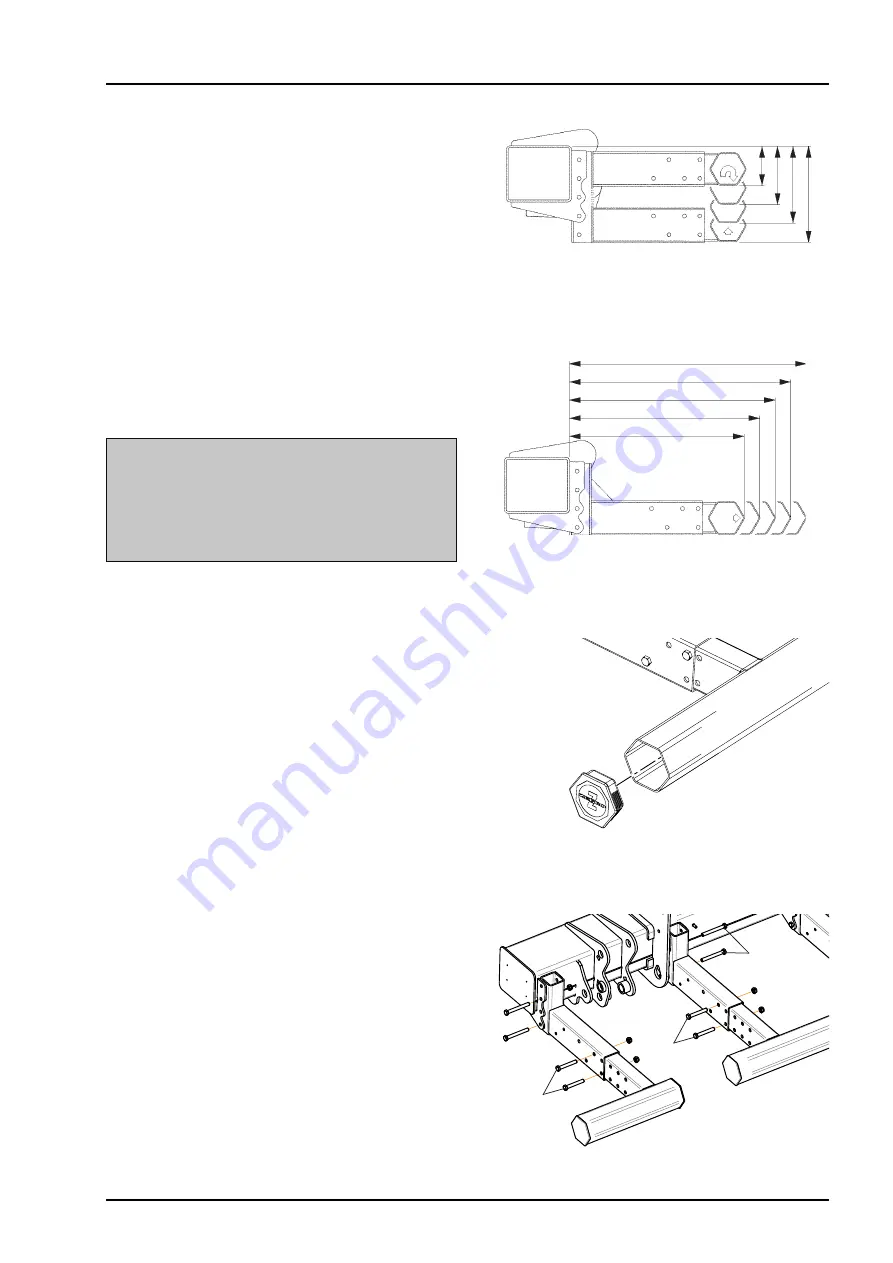

4.5.1

Underrun protection

Test the position of the underrun protection without

tightening the bolts to check that the statutory

dimensions are obtained. Adjust if necessary then

tighten the bolts with a torque wrench.

1. Fit the inner part of each bracket at one of four

heights. Select the height that meets the statuto-

ry requirements, see section "3.2 Statutory dimen-

sions" on page 9. Use the corresponding bolts

M12x100. Assemble without tightening the bolts,

see Image 46.

2.

Fit the outer part of each bracket at one of five

positions. Select a position that meets the statu-

tory requirements, see section "3.2 Statutory

dimensions" on page 9.

Use the corresponding bolts M12x80. Assemble

without tightening the bolts. See Image 47.

3. Check that the installation meets the statutory

requirements.

4. Tighten all the bolts using a torque wrench.

Tightening torque: 80 Nm.

5. Fit the member end caps, rotated so the logo is

the right way up, and press them firmly to secure.

If necessary, tap carefully with a rubber hammer.

Image 46. The inner part of the brack-

ets can be fitted at one of four heights

Image 47. The outer part of the brack-

ets can be fitted in one of five positions

Image 48. Fit the member end caps

Image 49. Installing underrun protection

133

193

241

301

617

667

717

767

817

m

WARNING!

Check carefully that there is no risk of the outer

part of each bracket colliding with any part of

the cylinders when using the lift’s functions. In

particular, check in relation to the cylinders’ hose

connections, especially when the outer part of the

brackets is installed a long way in.

Summary of Contents for ZDK 250 135

Page 2: ......

Page 65: ...ZDK 250 135 155 Registration 65 www zepro com...