ZHD 2500-130/150

Installation

21

www.zepro.com

6.4

Main power cable

6.4.1

Cable routing

1. Route the main power cable from the lift to the battery.

Route the cable through a plastic casing and ensure

it is not clamped to the brake line or the vehicle's existing electrical system.

The cable must not be clamped to brake lines or the normal on-board electrical system.

The cable must be protected by rubber grommets when it passes through beams or walls, see Image 20.

The cable must be installed sufficiently far

from, or be protected against, sharp edges so that it cannot

chafe or otherwise sustain damage that can lead to a short circuit and cable fires.

Do not bend the cable with too small a radius as this can cause damage to the cable.

In general, care must be taken when routing all the cables in order to obtain a longer cable service life

and to reduce the risk of unnecessary stoppages.

NOTE!

The fuse box must be located in a well protected position as close to the battery as possible.

NOTE.

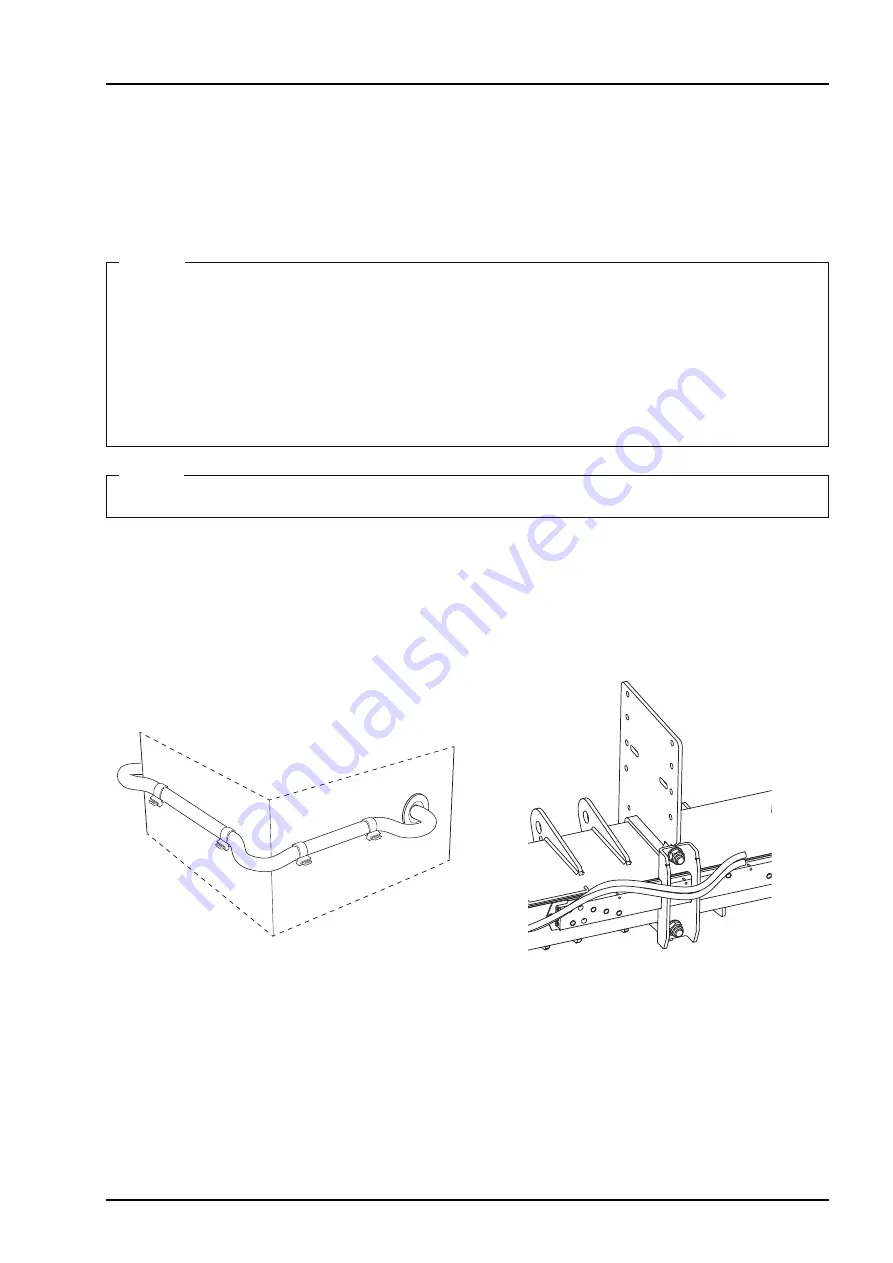

2.

Check that the hydraulic unit is effectively earthed. Certain commercial vehicle manufacturers provide

special earth connection points.

3. Connect the main power cable to the hydraulic unit, see "9 Electrical and hydraulic diagrams" on page 35.

Image 20. Protect the cable against sharp

edges and use cable grommets

Image 21. Earth and supply cables must

be routed outside clamping yoke