Installation & Operation • 21

INSTALLATION & OpERATION

Rear load Cases

Rear load cases are shipped with the rear sliding doors removed and shipped loose with the case. To maintain proper temperature, the Rear

load case must be positioned in the opening of a walk-in cooler. Before attaching the cases to the walk-in, measure the diagonal opening of the

Rear load case to ensure a square case installation. If the diagonal measurements are not within 1/8", the case must be re-leveled. After the

cases are set, install the doors into the opening by inserting the top of the door into the upper track and then sliding the bottom of the door into

the lower track.

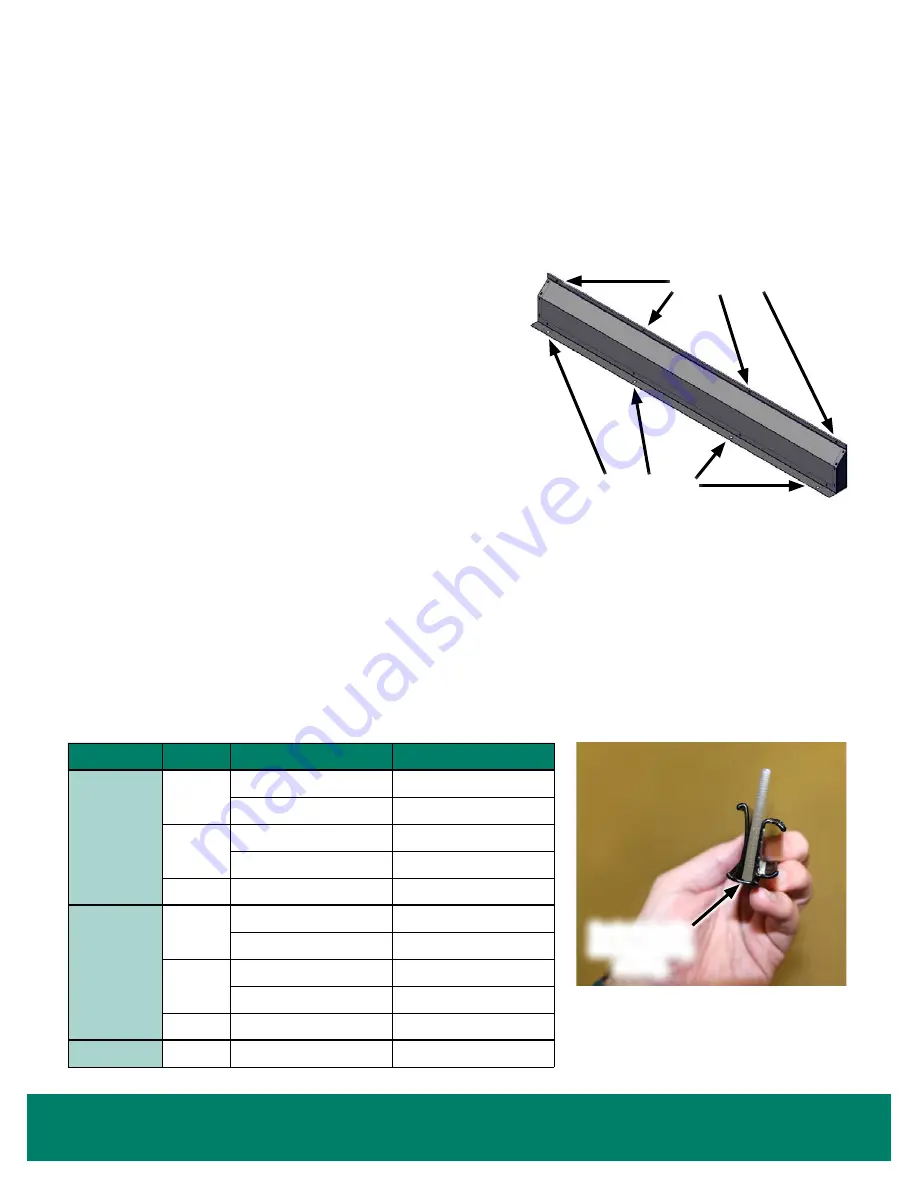

Rear load cases may be ordered with an optional insulated close-off for

applications where a walk-in cooler does not have a curb along the floor (

). After the case is set, the close-off must be installed to the bottom

rear of the display case. It protects the display case from potential damage if a

pallet of food or beverages is smashed into the back of the display case. It also

prevents warm air from entering the walk-in cooler and prevents water from

flowing underneath the display case.

Shelves & Stocking Product

Shelf location may be adjusted in 1" vertical increments in any position for best

display advantage. Make sure the shelf brackets are securely seated before

placing any product on the shelf. The standard shelves may be tilted down at a

10° angle. Optional shelf assemblies are available that may be tilted at 5°, 10°, or 15° angle.

The case may be stocked with product after it has operated at least 24 hours with correct case temperature and proper control operation. When

stocking the shelves, leave a gap between the product and the shelf above, which allows an air curtain on top of the product. Product should not

extend beyond the front of the shelves or bottom wire rack. Do not exceed shelf load capacity (

).

To unassemble a shelf, insert a putty knife between the side of the shelf and the shelf bracket. Pry the pieces apart to disengage the bracket.

Shelves can be ordered with 1", 2", or 3" acrylic product stops, which fit into aluminum price tag molding. Slide the product stop into the price

tag molding and push it down to the bottom of the channel (

). The channel of the price tag molding may need to be pried open

with a screwdriver, but the product stop should slide in easily once started.

FIGURE 28: Rear Load Insulated Close-Off

Fasten to Floor

Fasten to Case

SHELF TYPE

DEPTH

BRACKET TYPE

LOAD CAPACITY (LBS.)

Solid Shelf,

Standard Duty

22"

2-Position (0°/10°)

250/150

4-Position (0°/5°/10°/15°)

250/250/150/100

24"

2-Position (0°/10°)

250/150

4-Position (0°/5°/10°/15°)

250/250/150/100

27"

2-Position (0°/10°)

250/150

Solid Shelf,

Heavy Duty

22"

2-Position (0°/10°)

350/150

4-Position (0°/5°/10°/15°)

350/250/150/100

24"

2-Position (0°/10°)

350/150

4-Position (0°/5°/10°/15°)

350/250/150/100

27"

2-Position (0°/10°)

350/150

Wire Shelf

22"

2-Position (0°/10°)

250/150

FIGURE 29: Shelf Load Capacities

FIGURE 30: Acrylic Product Stops (1" Shown)

Product stop fits

into the price tag

molding.