Installation & Operation • 7

INSTALLATION & OpERATION

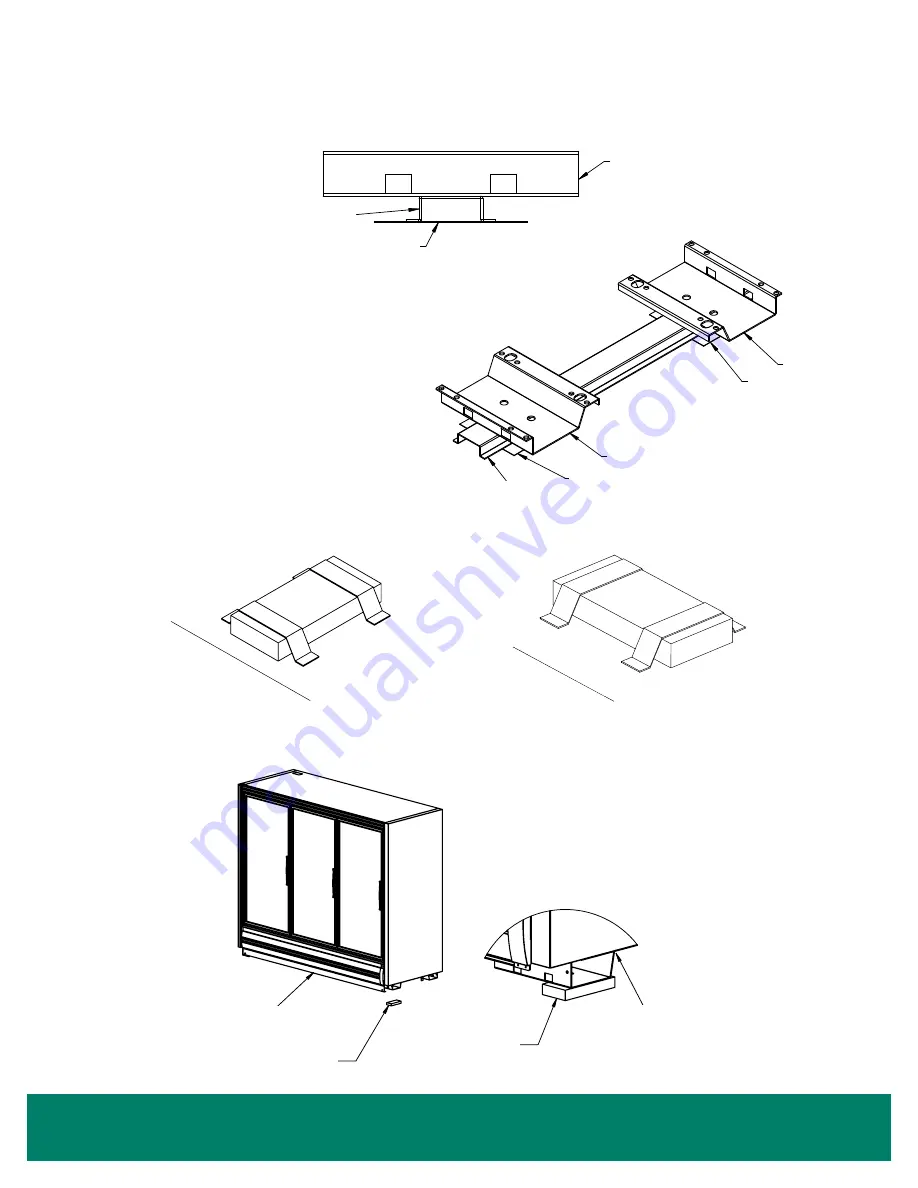

Hat Channel Rail

Hat Channel Rail

Shim

Shim

Shim

Base

Base

Base

Position hat channel rails with tape up. Place shims

perpendicularly under the hat channel rails.

2-door cases get 2 hat channel rails.

3 and 4-door cases get 3 hat channel rails.

Do not position under the drain hub.

5-door cases get 4 hat channel rails.

FIGURE 7: Hat Channel Rail Orientation

FIGURE 8: Tape Shims on the Floor Under Each Base or Hat Channel Rail

Cas

e F

ron

t

Case

Fr

ont

Placement

under Bases

Case Front

Case Front

Placement under

Hat Channel Rails

FIGURE 9: Shims Under Bases (Without Hat Channel Rails)

Shims must be placed under the front

and rear bends of each base to prevent

the base from warping/buckling.

Case

Shims

Case

Shims

Both corners of the base

must be supported by shims

to prevent base buckling

DWG. NO. SP-6006-1 REV. A

Display Case

Shims

Shims

Display Case