16 • Defrosting

DEFROSTING

Preferred Termination:

For optimal performance, Zero Zone recommends a temperature-terminated defrost, using a defrost termination

thermostat or probe attached to the dump line. At ASHRAE test conditions, termination ranges from 12-22 minutes. If the cases are so

equipped, the defrost termination is 65°F at the dump line. Zero Zone provides a defrost termination thermostat unless a control system defrost

probe is requested.

Defrost Operation

ELECTRIC DEFROST

The compressor stops when the defrost is initiated in a non-pump-down system. On pump-down systems, the liquid line solenoid will be de-

energized when the defrost is initiated. The clock will energize the defrost contactor, which will energize the defrost heater. This de-energizes

the 115-volt fans and anti-sweat heaters.

HOT GAS DEFROST

Several types of hot gas defrost methods (using time-actuated, time-terminated or temperature-terminated defrost timers) can be used to

defrost the evaporator.

The refrigeration system designer and installer are responsible for correct line sizing for effective hot gas defrost and liquid return from the

freezers. Sizing and component selection depend on the type of defrost, size, and location of high side refrigeration system.

Zero Zone freezers equipped for hot gas defrost consist of a side port distributor and a TXV check valve for coil defrost, and a suction line check

valve to bypass hot gas to the serpentine coil. The serpentine coil is attached to the bottom of the pan to ensure pan and drain defrost.

The timer starts the hot gas defrost cycle by energizing a solenoid, reversing valve, or directional valve. The hot gas is injected from the source

into the suction line of the evaporator to be defrosted. The hot gas flows into the serpentine coil attached to the floor of the case and then into

the evaporator. Condensed liquid leaves the evaporator through the side port distributor, through a check valve into the liquid line.

General Notes

The refrigeration technician should recheck coil condition after one week of retail operations to be certain that the frequency and duration

of defrost is adequate for the particular store and locality. For example, if defrost voltage is below 200 volts, additional fail-safe time may be

required.

When using time terminated defrost, the defrost termination thermostat should be wired in series with the defrost heater.

Defrost termination thermostats may be wired in series for multiple evaporator installations.

Defrost termination thermostats may be used as a digital input for electronic controllers.

Limit Thermostat

Each freezer has factory-set limit thermostats (Klixons) attached to the coil on the right end of the freezer to regulate the operation of the

evaporator fans and defrost heater.

!

CAUTION!

IMPORTANT! OPERATION OF THE LIMIT THERMOSTATS CAUSES THE EVAPORATOR FANS TO REMAIN

OFF UNTIL THE COMPRESSOR IS OPERATING AND THE COIL TEMPERATURE IS BROUGHT BELOW THE

THERMOSTAT CUT-IN SETTING (10°F ). SUPERHEAT MUST BE SET CORRECTLY BY THE INSTALLING

CONTRACTOR FOR PROPER THERMOSTAT OPERATION.

Summary of Contents for CRYSTAL MERCHANDISER

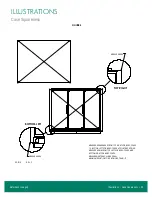

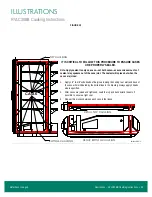

Page 25: ...Illustrations Case Squareness 23 Illustrations Figure 6 Case Squareness Refer back to page 5...

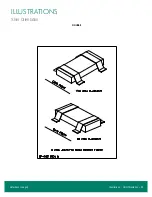

Page 26: ...24 Illustrations Shim Placement Illustrations Figure 7 Shim Placement Refer back to page 5...

Page 27: ...Illustrations Shim Orientation 25 Illustrations Figure 8 Shim Orientation Refer back to page 5...

Page 29: ...Illustrations Spacer Block 27 Illustrations Figure 10 Spacer Block Refer back to page 6...

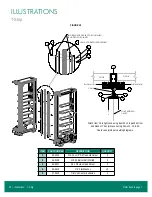

Page 34: ...32 Illustrations Drain Line Illustrations Figure 15 Drain Line Refer back to page 7...

Page 38: ...36 Illustrations Electrical Box Illustrations Figure 19 Electrical Box Refer back to page 11...