Installation & Operation • 15

INSTALLATION & OPERATION

Canopy Lights

Canopy lights can be angled to provide the best lighting for the product. We recommend adjusting these while stocking the case.

Shelves & Stocking Product

Shelf location may be adjusted in 1" vertical increments in any position for best display advantage. Make sure the shelf brackets are securely

seated before placing any product on the shelf. The standard shelves may be tilted down at a 10° angle. Optional shelf assemblies are available

that may be tilted at 5°, 10°, or 15° angle. Bottom wire racks are available as either flat with front fence or adjustable with front fence, which can

be set with a 15° angle.

The case may be stocked with product after it has operated at least 24 hours with correct case temperature and proper control operation.

Peg hooks require airflow baffles above each set to maintain proper product temperatures. When stocking the shelves, leave a gap between

the product and the shelf above, which allows an air curtain on top of the product. Angled, tiered, or lightly stocked shelves will reduce the air

curtain and may require lower evaporator temps. Product should not extend beyond the front of the shelves or bottom wire rack.

Note: Do not

place product on the return air grille or past the load limit line. Do not exceed shelf load capacity

(

. Do not stand on the

case when stocking or adjusting shelves.

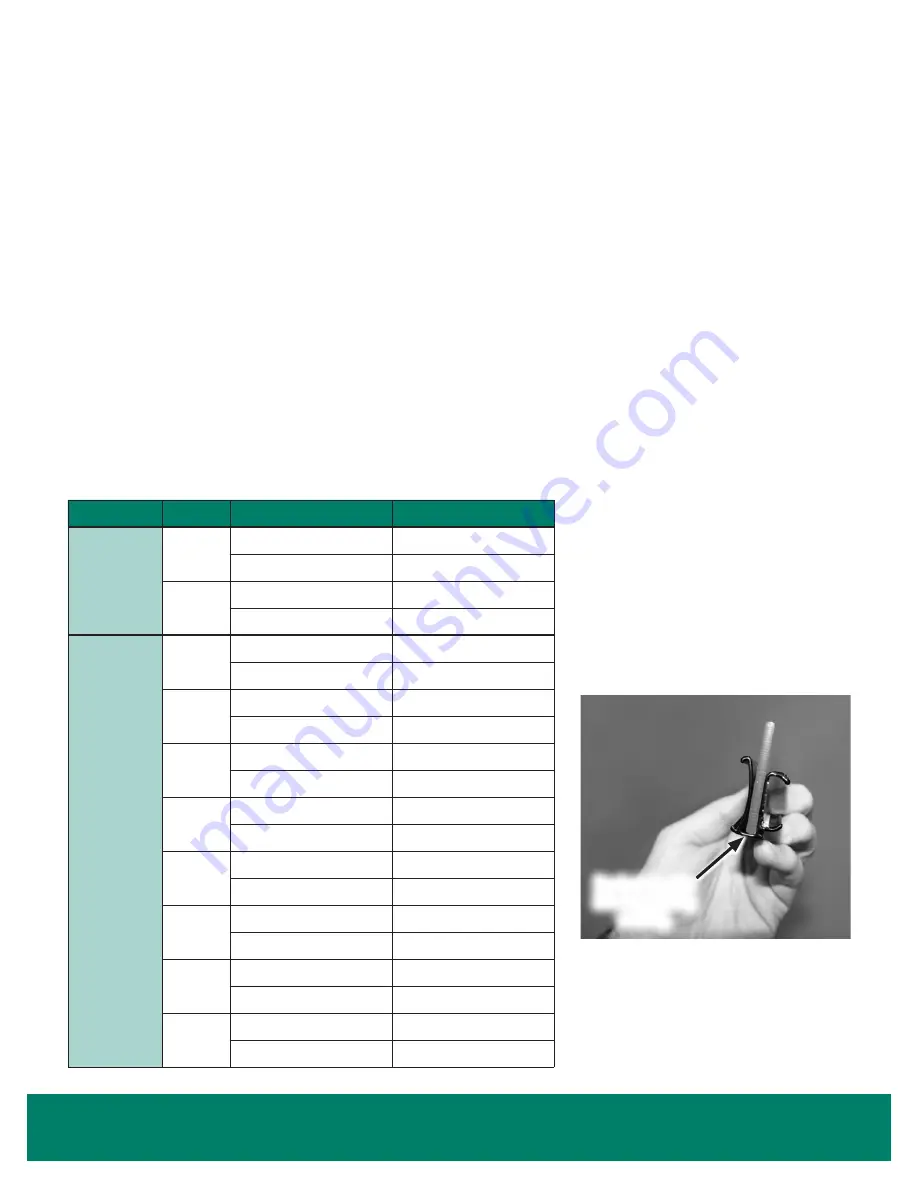

SHELF TYPE

DEPTH

BRACKET TYPE

LOAD CAPACITY (LBS.)

Solid Shelf,

Standard Duty

22"

2-Position (0°/10°)

250/150

4-Position (0°/5°/10°/15°)

250/250/150/100

24"

2-Position (0°/10°)

250/150

4-Position (0°/5°/10°/15°)

250/250/150/100

Solid Shelf,

Heavy Duty

10"

2-Position (0°/10°)

350/275

4-Position (0°/5°/10°/15°)

350/300/275/250

12"

2-Position (0°/10°)

350/275

4-Position (0°/5°/10°/15°)

350/300/275/250

14"

2-Position (0°/10°)

350/275

4-Position (0°/5°/10°/15°)

350/300/275/250

16"

2-Position (0°/10°)

350/275

4-Position (0°/5°/10°/15°)

350/300/275/250

18"

2-Position (0°/10°)

350/275

4-Position (0°/5°/10°/15°)

350/300/275/250

20"

2-Position (0°/10°)

350/275

4-Position (0°/5°/10°/15°)

350/300/275/250

22"

2-Position (0°/10°)

350/275

4-Position (0°/5°/10°/15°)

350/300/275/250

24"

2-Position (0°/10°)

350/275

4-Position (0°/5°/10°/15°)

350/300/275/250

FIGURE 28: Shelf Load Capacities

FIGURE 29: Acrylic Product Stops (1" Shown)

Product stop fits

into the price tag

molding.

Shelves can be ordered with 1", 2", or 3" acrylic

product stops, which fit into aluminum price tag

molding. Slide the product stop into the price tag

molding and push it down to the bottom of the

). The channel of the

price tag molding may need to be pried open with

a screwdriver, but the product stop should slide in

easily once started.