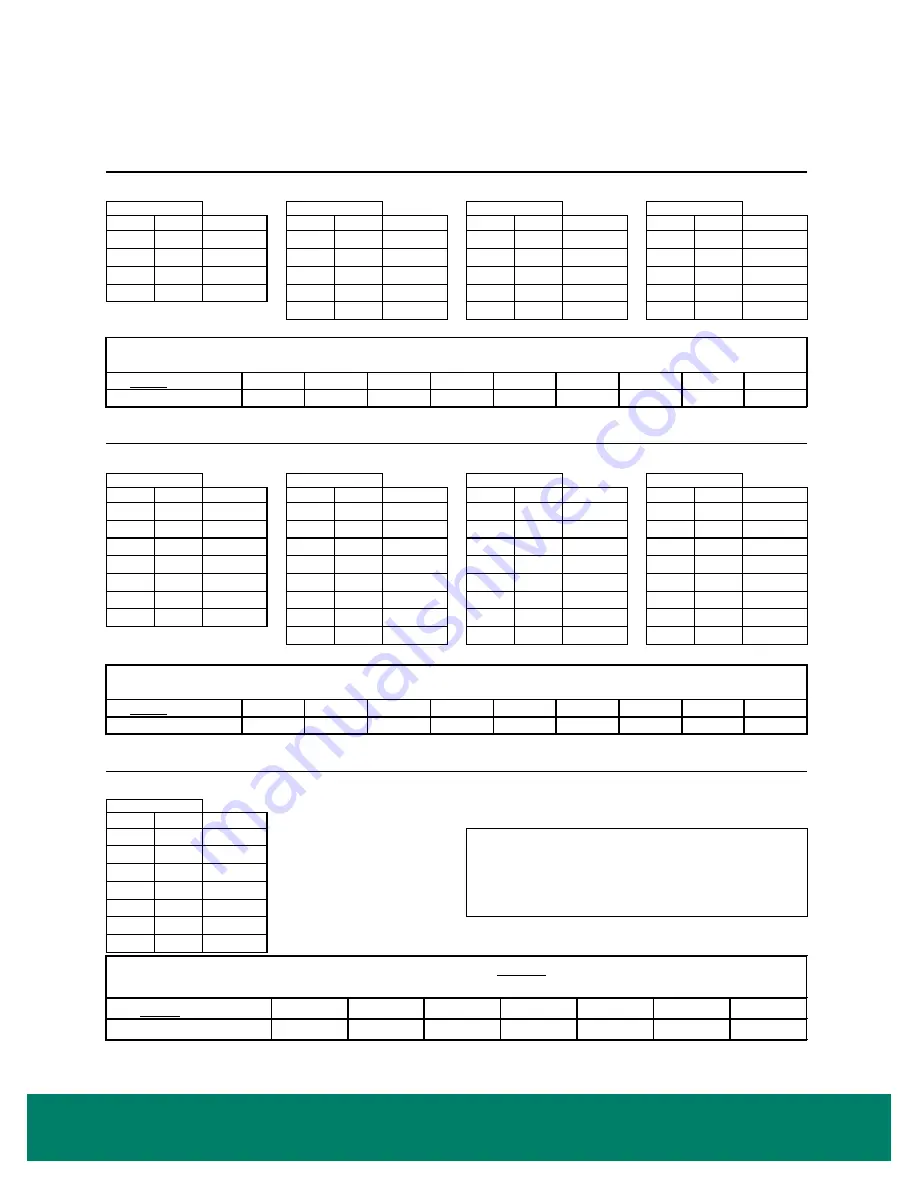

Refrigeration • 17

REfRIgERATION

From

To

Liquid Line

From

To

Liquid Line

From

To

Liquid Line

From

To

Liquid Line

5,280

30,720

3/8

5,280

21,010

3/8

5,280

16,790

3/8

5,280

14,310

3/8

30,730

72,750

1/2

21,020

49,900

1/2

16,800

39,960

1/2

14,320

34,110

1/2

72,760 136,380

5/8

49,910

93,740

5/8

39,970

75,160

5/8

34,120

64,210

5/8

136,390 226,300

3/4

93,750 155,790

3/4

75,170 125,030

3/4

64,220 106,890

3/4

155,800 246,590

7/8

125,040 198,070

7/8

106,900 169,440

7/8

From

To

Horizontal

From

To

Horizontal

From

To

Horizontal

From

To

Horizontal

5,280

8,350

1/2

5,280

5,730

1/2

---

---

---

---

---

---

8,360

15,640

5/8

5,740

10,760

5/8

5,280

8,630

5/8

5,280

7,380

5/8

15,650

25,950

3/4

10,770

17,880

3/4

8,640

14,360

3/4

7,390

12,280

3/4

25,960

41,010

7/8

17,890

28,290

7/8

14,370

22,740

7/8

12,290

19,460

7/8

41,020

82,770

1-1/8

28,300

57,220

1-1/8

22,750

46,030

1-1/8

19,470

39,430

1-1/8

82,780 143,860

1-3/8

57,230

95,580

1-3/8

46,040

80,190

1-3/8

39,440

68,720

1-3/8

143,870 226,880

1-5/8

95,590 157,230

1-5/8

80,200 126,700

1-5/8

68,730 108,640

1-5/8

157,240 325,130

2-1/8

126,710 262,250

2-1/8

108,650 225,030

2-1/8

From

To

Vertical

5,280

6,590

5/8

6,600

10,500

3/4

10,510

21,300

7/8

21,310

37,300

1-1/8

37,310

59,100

1-3/8

59,110 121,880

1-5/8

121,890 215,800

2-1/8

90°F Liquid, 2°F Pressure Drop

‡

Up to 50 equivalent feet

‡

For 1°F pressure drop, multiply rated Btuh by 1.44 before using the Suction Horizontal Line Sizing Table.

∆

For 1°F pressure drop, multiply rated Btuh by 1.45 before using the Liquid Line Sizing Table.

Suction Vertical Riser Sizing

Up to 100 equivalent feet

Up to 50 equivalent feet

90°F Liquid, 2°F Pressure Drop

∆

Up to 100 equivalent feet

Up to 200 equivalent feet

90°F Liquid, 2°F Pressure Drop

∆

Liquid Line Sizing

Suction Horizontal Line Sizing

90°F Liquid, 2°F Pressure Drop

‡

Up to 200 equivalent feet

90°F Liquid, 2°F Pressure Drop

‡

Up to 150 equivalent feet

90°F Liquid, 2°F Pressure Drop

‡

Up to 150 equivalent feet

90°F Liquid, 2°F Pressure Drop

∆

It may be necessary to make adjustments to compensate for special situations

which cause the actual Btuh to differ from the rated Btuh of the cases.

All liquid line and suction line sizes are inches, refrigeration O.D.

Subject to change without notice.

70°F Minimum Liquid Temperature, using 0.35 PSI Per 100 Feet (per 2006 ASHRAE Handbook - Refrigeration)

For rated Btuh:

Maximum Allowable Riser Size For Adequate Oil Return*

R-404 Line Sizing Tables for Zero Zone OVMC Multideck (+26°F Evaporator Temperature)

For rated Btuh:

For rated Btuh:

For rated Btuh:

For rated Btuh:

For rated Btuh:

For rated Btuh:

For rated Btuh:

For rated Btuh:

90°F Liquid, 2°F Pressure Drop

∆

Liquid Correction Factors for Suction Vertical Riser Sizing Table - Use Minimum Liquid Temperature

Multiply rated Btuh by liquid correction factor before using the Suction Vertical Riser Sizing Table

40°F

50°F

60°F

70°F

80°F

90°F

100°F

0.85

0.89

0.94

1.00

1.07

1.15

1.24

Minimum Liquid Temperature:

Liquid Correction Factor:

40°F

50°F

60°F

70°F

80°F

90°F

100°F

120°F

0.74

0.78

0.82

0.87

0.93

1.00

1.08

1.32

1.19

Liquid Correction Factors for Suction Horizontal Line Sizing Table - Use Maximum Liquid Temperature

For max imum liquid temperatures other than 90°F, multiply rated Btuh by liquid correction factor before using the Suction Horizontal Line Sizing Table

Max imum Liquid Temperature:

110°F

Liquid Correction Factor:

40°F

50°F

60°F

70°F

80°F

90°F

100°F

120°F

0.98

0.97

0.96

0.97

0.98

1.00

1.04

1.17

Liquid Correction Factors for Liquid Line Sizing Table - Use Maximum Liquid Temperature

For maximum liquid temperatures other than 90°F, multiply rated Btuh by liquid correction factor before using the Liquid Line Sizing Table

Max imum Liquid Temperature:

110°F

Liquid Correction Factor:

1.09

FIGURE 32: R-404A Line Sizing Tables for Zero Zone ORMC Multi-Deck (26°F Evaporator Temperature)