Page 4

OPERATING INSTRUCTIONS FOR COOLER

It is important to read through these instructions carefully before operating the cooler.

This instruction manual should be kept in a safe place for future reference.

GAS THERMOSTAT OPERATION

USER OPERATING INSTRUCTIONS

Note: Appliance cannot be run off 2 heat sources at the same time.

TO START GAS OPERATION

1. Open the shut-off valve for the gas bottle (check that there is enough gas).

Open any shut-off valve of the gas installation.

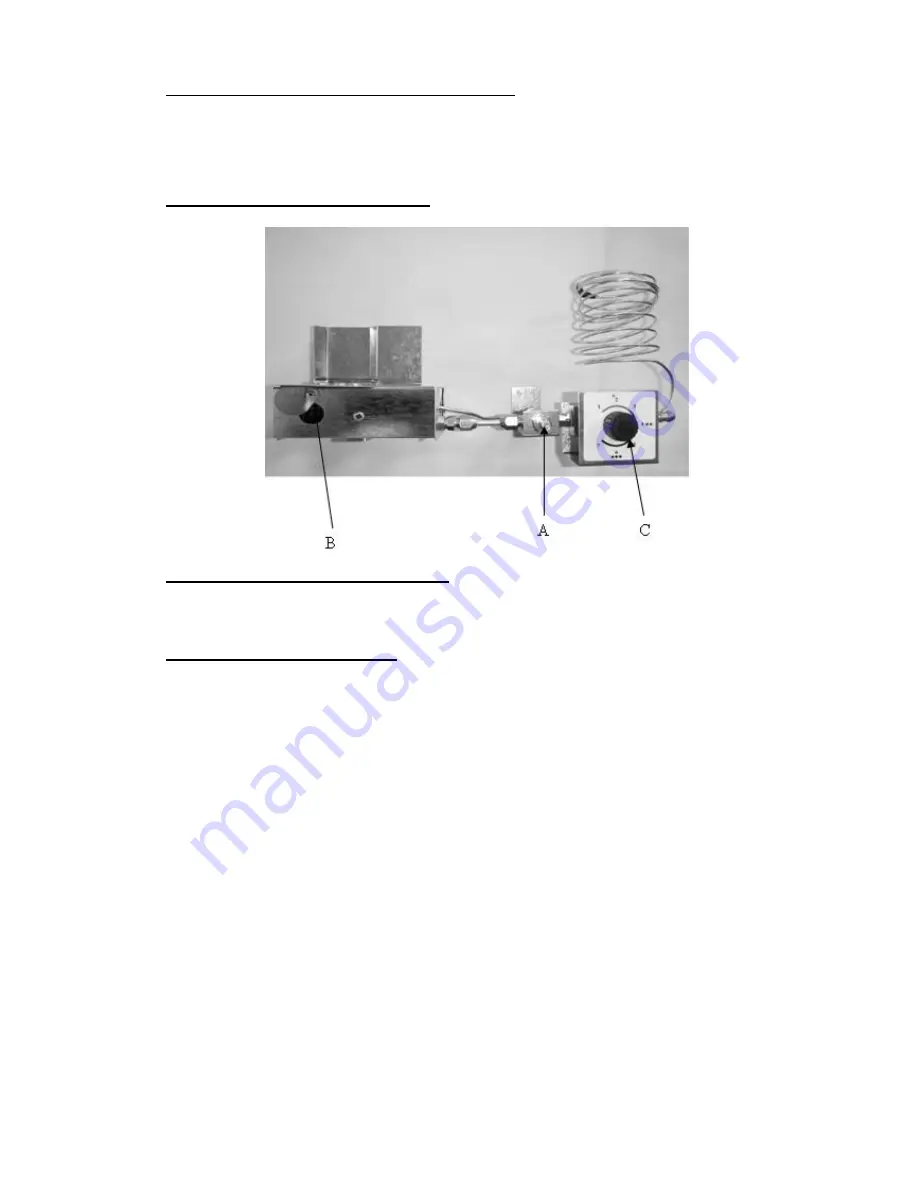

2. Open flap B.

3. Keep the flame failure device knob (A) pressed in for approximately 15 seconds.

4. Release for 10 seconds, strike match and insert into flap hole. Press (A) again.

5. Keep the knob (A) pressed in for a further 15 seconds then release it. If the flame

goes out, repeat steps 2, 3 and 4 until the flame stays alight.

To terminate the gas operation turn off the shut-off valve on the gas bottle.

On starting the cooler, it will take a few hours to start becoming cold.

Once the burner (B) has been lit turn the gas thermostat (C) to position ‘7’ for

maximum cooling (clockwise).

By adjusting the thermostat (C) knob down from position ‘7’ you can regulate the

temperature you desire in the bottle cooler.

NOTE:

The gas safety valve knob (A) should never be depressed for periods longer than

15 seconds with the burner unlit, as this can cause a potentially dangerous build-

up of unburnt gas. If the burner does not ignite, allow sufficient time for any

unburnt gas to disperse, then repeat the ignition steps.

Summary of Contents for GR250BC

Page 11: ...Made in South Africa Pty Ltd...

Page 12: ......