zero

HOME AUTOMATION

Z02 - SWING GATE

PG3

INDEX

01.

SAFETY INSTRUCTIONS

02. OPERATOR

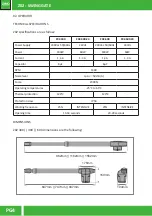

TECHNICAL SPECIFICATIONS

DIMENSIONS

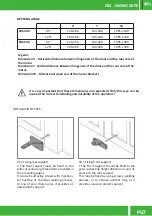

03. INSTALLATION

INSTALLATION DIMENSIONS

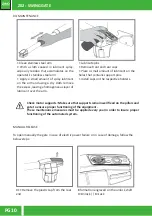

INSTALLATION STEPS

TYPICAL INSTALLATION

04. MAINTENANCE

MANUEL RELEASE

05. TROUBLESHOOTING

01. SAFETY INSTRUCTIONS

ATTENTION:

•To ensure the safety of people, it is important that you read all the following instructions.

Incorrect installation or incorrect use of the product can cause physical injury and material

damage.

•Keep these instructions in a safe place for future reference.

•This product was designed and produced strictly for the use indicated in this manual. Any

other use, not expressly indicated here, could compromise the good condition/ operation of

the product and/or be a source of danger.

•ZERO SRLS. is not responsible for the improper use of the product, or other use than that

for which it was designed.

•ZERO SRLS. is not responsible if safety standards were not taken into account when instal

-

ling the equipment, or for any deformation that may occur to it.

•ZERO SRLS. is not responsible for the safety and proper operation when using components

not sold by them.

•Do not make any modifications to the operator components and / or their accessories.

•Before installation unplug the automatism from the source of power.

•The installer must inform the client how to handle the product in case of emergency and

provide this manual to user.

•Keep remote controls away from children, to prevent the automated system from being

activated involuntarily.

•The customer shall not, under any circumstances, attempt to repair or tune the operator

.Must call qualified technician only.

•Connect the automatism to a 230V plug with ground wire.

•Operator for outdoor and indoor use.