152

MAINTENANCE INSTRUCTIONS

G715 D402

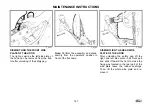

REASSEMBLY OF THE AIR CLEANER

ELEMENTS

When reassembling the air cleaner ele-

ments proceed in the reverse order.

Observe the following points during the

element reassembly:

- Make sure the contact surfaces are

clean.

- During the assembly the elements must

not get deformed and after installation

they must not vibrate.

- After closing of the cleaner with the lid

the whole cleaner must be perfectly

leak-proof.

- After the maintenance of the dry air

cleaner ensure proper functioning of

the clogging indicator again.

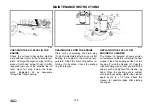

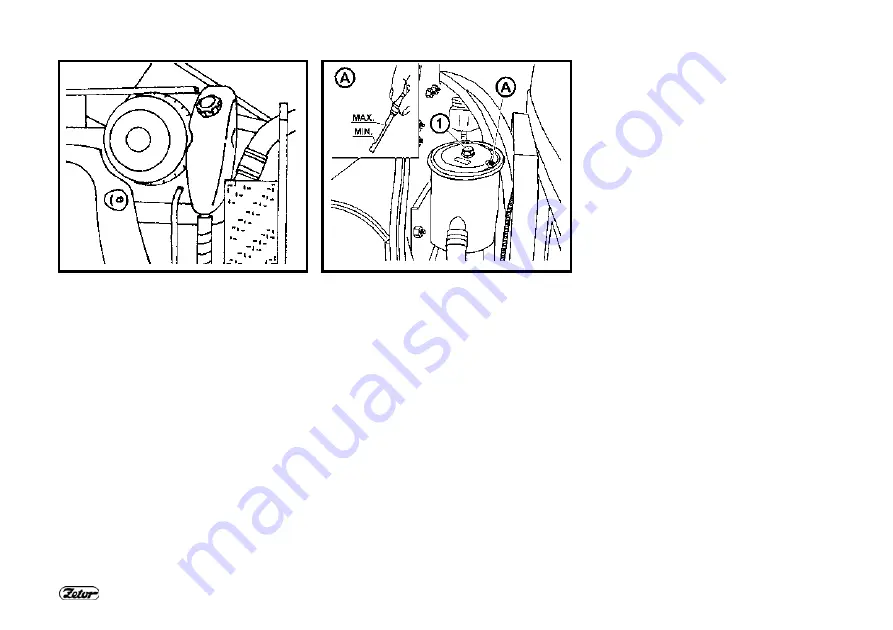

HYDROSTATIC STEERING OIL TANK

The tank is accessible after the removal

of the left rear side plate of the hood.

Use the dipstick (A) to check the oil level

in the hydrostatic steering tank; maintain

the oil level between the MIN and MAX

marks, see fig. (A).

If necessary, replenish oil after unscrew-

ing the nut (1) and removing the tank lid.

Summary of Contents for FORTERRA 105

Page 1: ......

Page 2: ......

Page 7: ...7 LOCATION OF SERIAL NUMBERS XH154...

Page 32: ...32 ACQUAINTANCE WITH THE TRACTOR B21a...

Page 34: ...34 ACQUAINTANCE WITH THE TRACTOR F54b...

Page 46: ...46 NOTES...

Page 64: ...64 NOTES...

Page 68: ...68 NOTES...

Page 80: ...80 NOTES...

Page 106: ...106 NOTES...

Page 120: ...120 NOTES...

Page 130: ...130 NOTES...

Page 176: ...176 NOTES...

Page 190: ...190 NOTES...

Page 197: ......