Work with PTO shaft

Before attaching of an implement, driven by means of the tractor PTO shaft, check the speed

compatibility of both, it means tractor PTO shaft and implement driven shaft (540 rpm or 1,000 rpm).

Different PTO speed values may cause serious damages and injuries.

Within any repair or modification on the implement powered by PTO or within any operation on

terrain in its working range the tractor engine ought to be switched off (ignition key in position 0).

1. When working with PTO shaft mind that all the covers are duly fixed.

2. After completing the work, always mount the cover of PTO shaft back.

3. Any repairs or cleaning of aggregated machines parts driven by PTO shaft to be done only with the

engine at halt and PTO clutch disengaged.

4. Before starting an aggregated machine driven by PTO shaft, make sure that there are no

unauthorized personnel near, there is a risk of injury.

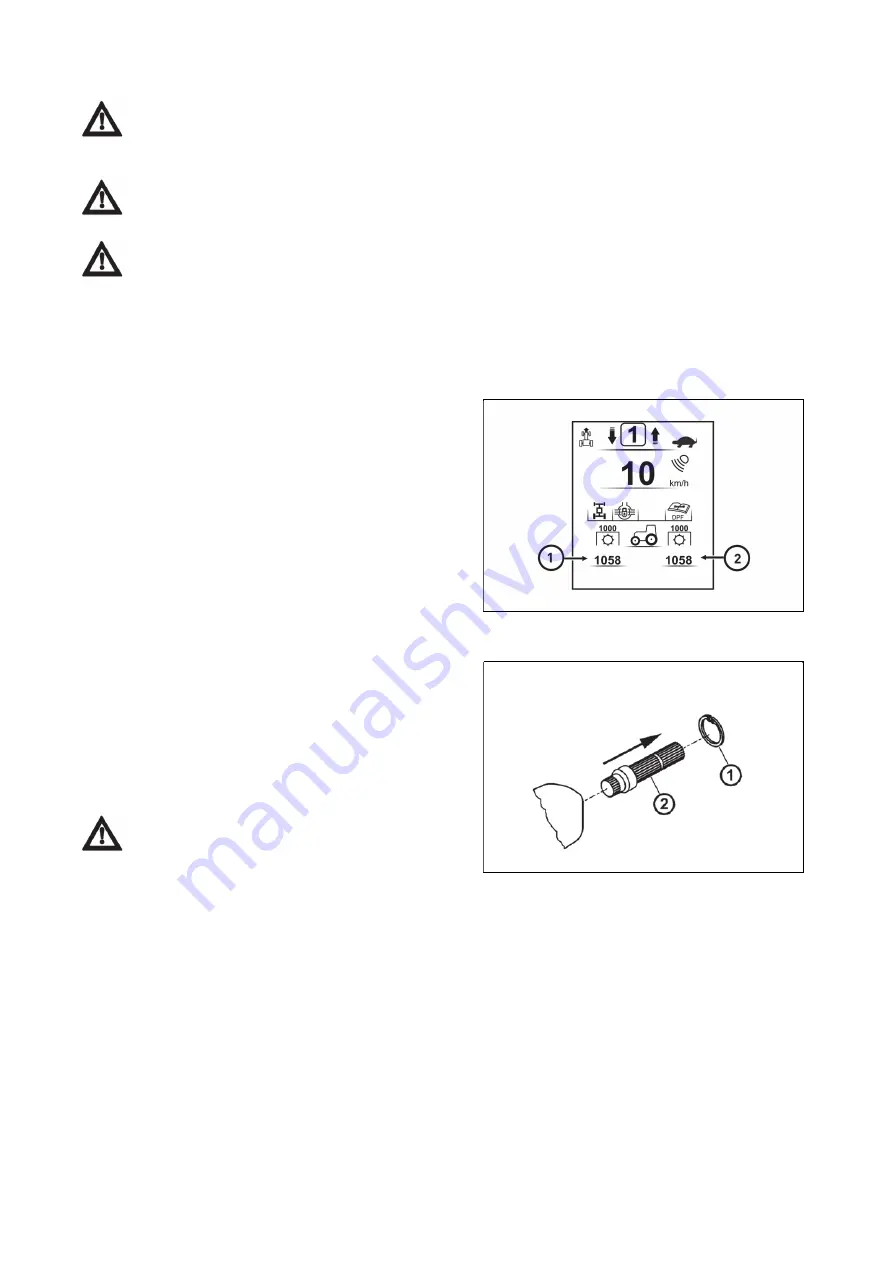

Display of revolutions of PTO shafts

Replaceable end points of rear PTO shaft

When the PTO shaft is switched on, the PTO shaft speed

is displayed on the instrument panel display.

1 - RPM of the front PTO shaft

2 - RPM of the rear PTO shaft

FHSX18N003

The tractor is equipped with six or twenty-one splined

replaceable end point of rear PTO shaft.

Replacement procedure:

1. Use safety ring pliers to demount a safety ring (1)

2. Remove replaceable end point by pulling in the

direction of an arrow (2)

3. Mount the end point in an opposite way, pay increased

attention to the mounting of the safety ring (1)

Replacement of the terminal shall be performed

when the engine is stopped.

Rpm of the output shaft and terminal type shall be

chosen depending on the prescribed rpm of the

coupled mechanism.

Shifting 540, 1,000, 1,000E or 540E min

-1

is possible

regardless to the number of splines of the installed

terminal.

E357

DRIVE OF AGRICULTURAL MACHINERY

131

Summary of Contents for FORTERRA HSX 120

Page 1: ...FORTERRA HSX 120 130 Tractor is Zetor Since 1946 140 OPERATOR S MANUAL 04 2020...

Page 3: ...2...

Page 93: ...NOTES 92...

Page 125: ...NOTES 124...

Page 131: ...NOTES 130...

Page 163: ...NOTES 162...

Page 179: ...Fuse panel B Tractors without light controller only FHSXS5N010 ELECTRIC INSTALLATION 178...

Page 181: ...Fuse panel B Tractors with light controller only FHSXS5N008 ELECTRIC INSTALLATION 180...

Page 195: ...NOTES 194...

Page 225: ...NOTES 224...

Page 230: ...229...